Preparation method for terbium oxide and yttrium oxide co-stabilized zirconia nano fluorescent ceramic powder

A technology of stabilizing zirconia and nano-fluorescence, which is applied in the field of preparation of rare earth luminescent materials, can solve the problems of particle agglomeration and sintering, small specific surface area, and limitations, and achieve good luminescence performance, easy availability of raw materials, and improved density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

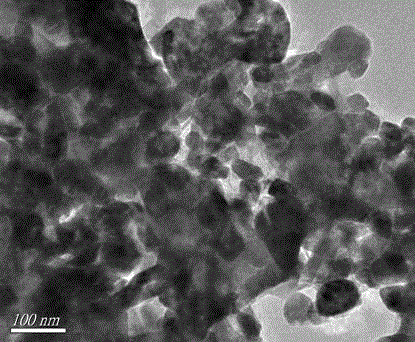

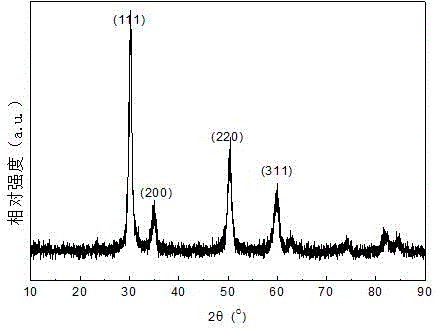

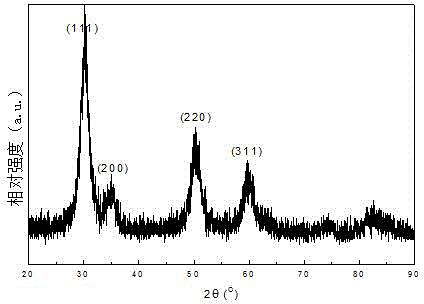

[0035] Weigh 3.0960g ZrOCl 2 ·8H 2 O,0.0339gY 2 o 3 and 0.0187g Tb 4 o 7 , adding an excess of 1:1 nitric acid and heating to dissolve Y 2 o 3 and Tb 4 o 7 , to form a clear solution of yttrium nitrate and terbium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain the mixed salt solution of the metal contained in the target product, then add 1.7532g NaCl and 1.7099g glycine to the solution, after heating to dissolve completely, continue heating and concentrating the mixed solution until viscous, put it into the The fixed temperature is 600°C and ignited in the fixed temperature cavity. After the combustion is completed, the sample is taken out, washed, filtered and dried to obtain a specific surface area of 123 m 2 g -1 of (Tb 4 o 7 ) 0.0025 (Y 2 o 3 ) 0.015 (ZrO 2 ) 0.96 Pale yellow powder.

Embodiment 2

[0037] Weigh 2.993g ZrOCl 2 ·8H 2 O, 0.0339gY 2 o 3 and 0.0748g Tb 4 o 7 , add excess 1:1 nitric acid and heat to dissolve Y 2 o 3 and Tb 4 o 7 , to form a clear solution of yttrium nitrate and terbium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain the mixed salt solution of the metal contained in the target product, then add 1.7532g NaCl and 1.7596g glycine to the solution, after heating to dissolve completely, continue to heat and concentrate the mixed solution until it is viscous, and put it into the set The temperature is 600°C and ignited in a constant temperature chamber. After the combustion is completed, the sample is taken out, washed, filtered, and dried to obtain a specific surface area of 171m 2 g -1 of (Tb 4 o 7 ) 0.010 (Y 2 o 3 ) 0.015 (ZrO 2 ) 0.930 Pale yellow powder.

Embodiment 3

[0039] Weigh 2.7410g ZrOCl 2 ·8H 2 O, 0.0339gY 2 o 3 and 0.2244g Tb 4 o 7 , adding an excess of 1:1 nitric acid and heating to dissolve Y 2 o 3 and Tb 4 o 7 , to form a clear solution of yttrium nitrate and terbium nitrate, the weighed ZrOCl 2 ·8H 2 O is completely dissolved in it to obtain a mixed salt solution of the metal contained in the target product, and then add 1.7532g NaCl and 1.8934g glycine to the solution, after heating to dissolve completely, continue to heat and concentrate the mixed solution until it is viscous, and put it into the set The temperature is 600°C and ignited in a constant temperature chamber. After the combustion is completed, the sample is taken out, washed, filtered, and dried to obtain a specific surface area of 120m 2 g -1 of (Tb 4 o 7 ) 0.030 (Y 2 o 3 ) 0.015 (ZrO 2 ) 0.850 Pale yellow powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com