Coating composition for drilling tool as well as preparation method and application thereof

A composition, coating technology, applied in the field of drilling, which can solve the problems of velcro, gaps, punctured shoulders and threads, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The invention provides a kind of preparation method of coating composition for drilling tool, comprises the following steps:

[0043] Dissolving nano-copper and polytetrafluoroethylene powder in an organic solvent to obtain an organic mixture;

[0044] The organic mixed liquid is mixed with a metal binder to obtain a coating composition for drilling tools.

[0045] The present invention preferably dissolves the nano-copper and polytetrafluoroethylene micropowder described in the above technical solution in an organic solvent to obtain an organic mixed liquid. The present invention has no special limitation on the way of dissolving. Nano-copper and polytetrafluoroethylene micropowder can be added to the organic solvent, or the organic solvent can be added to the mixed powder of nano-copper and polytetrafluoroethylene micropowder. A homogeneous organic mixture was obtained after stirring. The present invention has no special limitation on the method of stirring, and the...

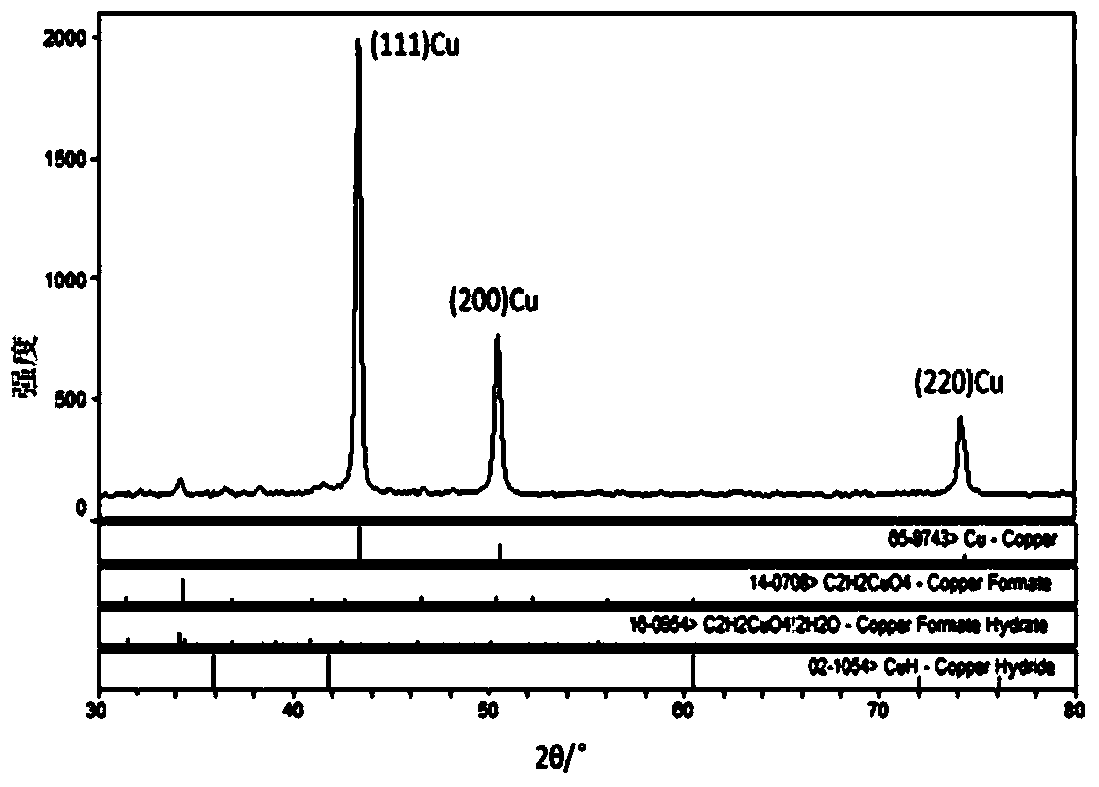

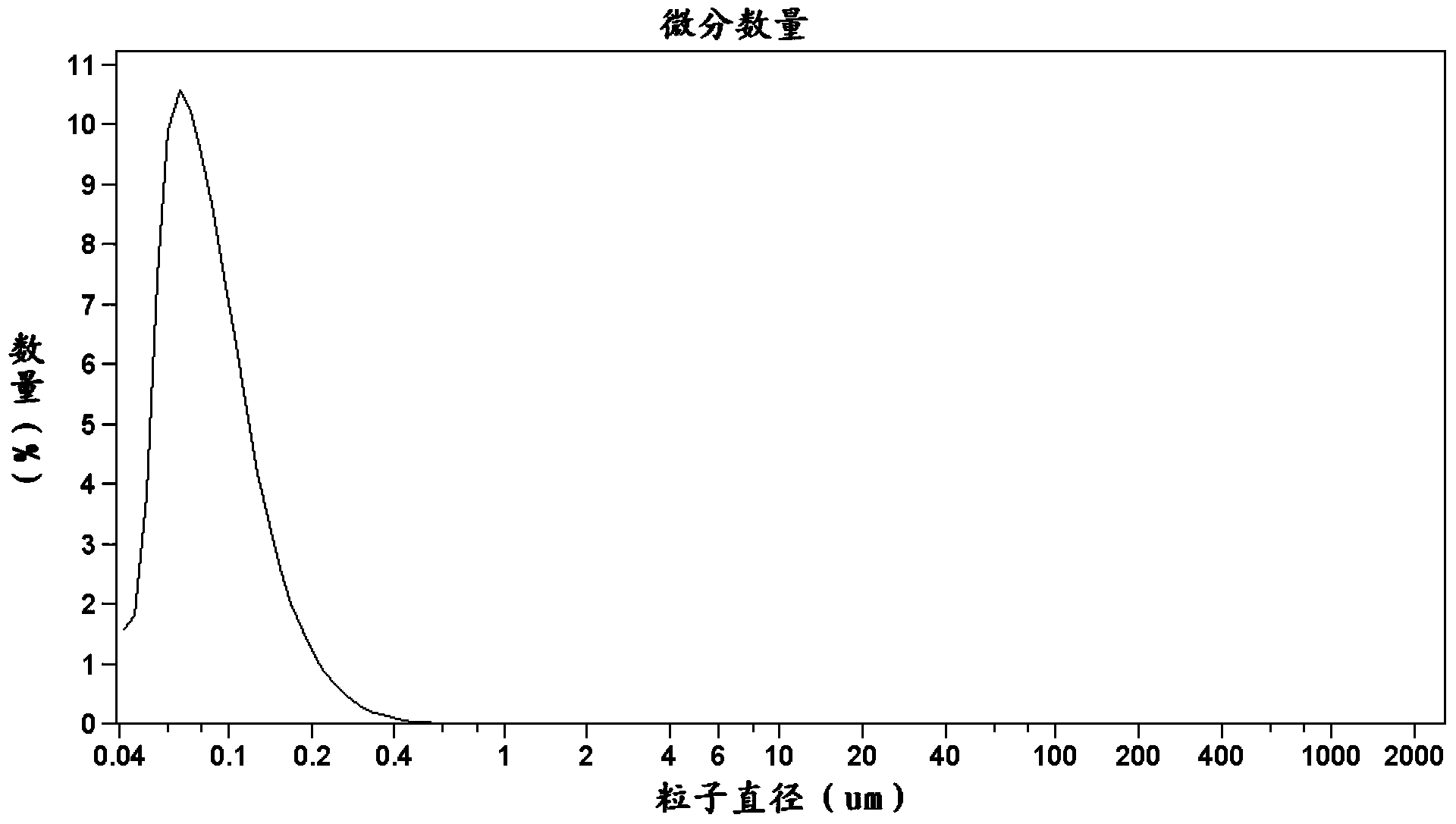

Embodiment 1

[0054] Add 12.5g of copper oxide with a mass purity of more than 98% to 100mL of absolute ethanol to dissolve, weigh 2g of polyvinylpyrrolidone and add it to the copper oxide solution obtained above, and place the obtained mixed solution in an ultrasonic oscillator for ultrasonication. Dispersion, the working frequency of the ultrasonic oscillator is 40KHZ, the oscillation time is 5min, and a uniform mixed solution is obtained;

[0055] Add 3.5g±0.2g of hydrazine hydrate solution with a mass concentration of 3.5g / 10mL to the obtained mixed solution, and complete the dropwise addition within 10 minutes;

[0056] Place the obtained mixed solution with reducing agent in an ultrasonic oscillator and oscillate at a working frequency of 20KHZ to 40KHZ. During the process of oscillating, the mixed solution will produce bubbles on nominal basis, and the liquid will slowly turn red, and the oscillating reaction will stop after 30 minutes. , the obtained reaction solution was left to st...

Embodiment 2

[0061] The polytetrafluoroethylene micropowder that the particle diameter D50 of 16 weight parts of embodiment 1 preparations and 5 weight parts is about 10nm is dissolved in the ethylene glycol monomethyl ether of 65 weight parts, after stirring evenly, add 14 wherein The cyanoacrylate binder in parts by weight is uniformly mixed to obtain the coating composition for drilling tools.

[0062] The coating composition for drilling tool obtained in this example was sprayed on the outer surface of the drilling tool thread, the drilling tool thread was a round thread, and the sprayed thickness was 12 μm, and the obtained drilling tool could be used after drying.

[0063] The present invention investigates the threaded connection of the drilling tool coated with the coating composition for the drilling tool provided by the present invention on an existing make-up machine to test its anti-friction performance.

[0064] First, with the maximum torque as the target make-up, the influen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| D5 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com