Electrolyte for lithium ion battery

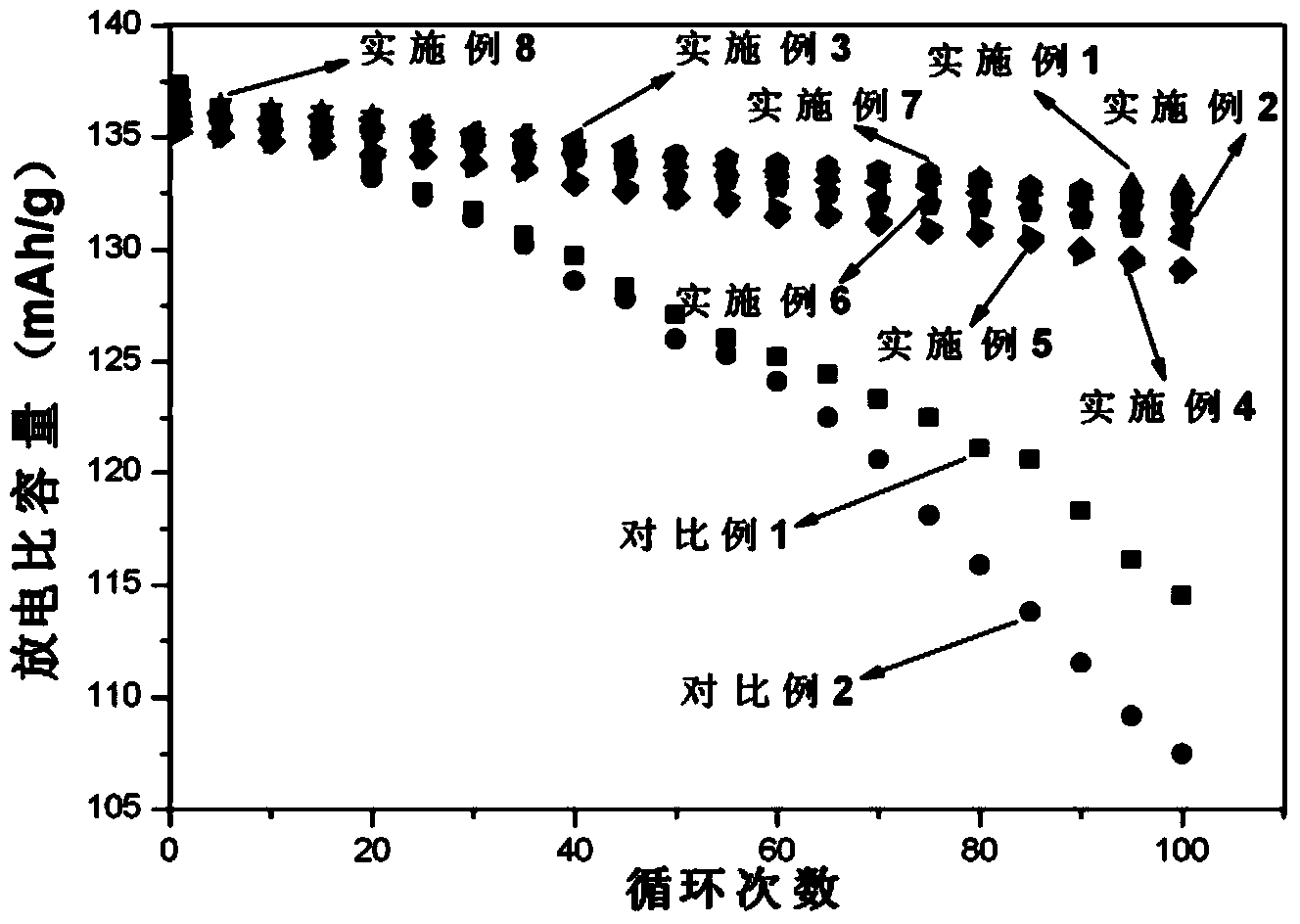

A lithium-ion battery and electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of low charging and discharging efficiency of lithium-ion batteries, poor cycle performance, restricting the development of high-voltage lithium-ion batteries, etc., so as to improve cycle performance and rate performance, Not easy to decompose and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

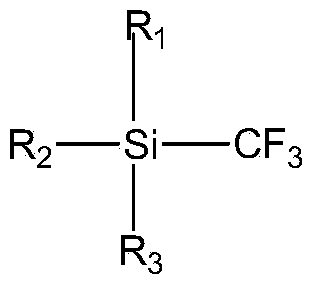

[0029] The present embodiment lithium-ion battery uses electrolytic solution:

[0030] According to the mass ratio of 1:1:1, ethylene carbonate, dimethyl carbonate, and ethyl methyl carbonate were respectively weighed to form mixed solvent A, and then mixed solvent A accounting for 50% of the total mass of the electrolyte was mixed with 35% of the total mass of the electrolyte. % trifluoromethyltrimethylsilane solvent mixed to form a mixed solvent B; in the mixed solvent B, add LiPF 6 Prepare an electrolyte solution with a lithium salt concentration of 1mol / L, and then add 1,3-propane sultone to obtain it. The amount of 1,3-propane sultone accounts for 2% of the total mass of the electrolyte.

Embodiment 2

[0032] The present embodiment lithium-ion battery uses electrolytic solution:

[0033] Weigh ethylene carbonate, dimethyl carbonate and diethyl carbonate according to the mass ratio of 2:2:1 to form mixed solvent A, and then mix solvent A accounting for 64% of the total mass of the electrolyte with 25% of the total mass of the electrolyte. % of trifluoromethyltriethylsilane solvent mixed to form mixed solvent B; in mixed solvent B, add LiClO 4 Make the lithium salt concentration 0.8mol / L, and then add 1,3-propane sultone to obtain it. The amount of 1,3-propane sultone accounts for 1% of the total mass of the electrolyte.

Embodiment 3

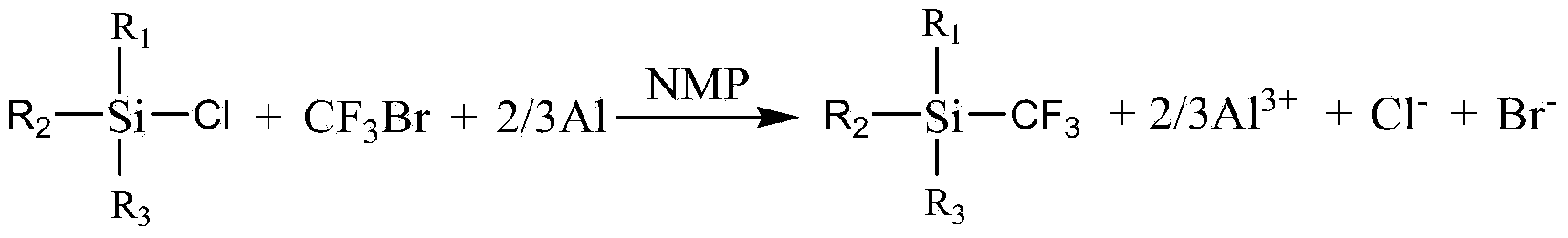

[0035] Synthesis of trifluoromethyl-n-propyldimethylsilane:

[0036] Add 70ml of N-methylpyrrolidone (NMP) into a 150ml stainless steel autoclave, then add 0.78g of aluminum powder (100-200μm), and then add 5.46g of propyl dimethyl chlorosilane and 6.2g of trifluoro Methyl bromide, heated at 50°C for 5 minutes to initiate the reaction, reacted at room temperature for 3 hours, and filtered. The filtrate was distilled at atmospheric pressure, and the fraction at 105°C was collected.

[0037] The present embodiment lithium-ion battery uses electrolytic solution:

[0038] Take by weighing propylene carbonate accounting for 25% of the total mass of the electrolyte, mix with trifluoromethyl-n-propyldimethylsilane accounting for 45% of the total mass of the electrolyte, and make a mixed solvent; add a mass ratio of 3 in the mixed solvent: 1:2 LiBF 4 , LiTFSI and LiFSI mixed lithium salt to make the lithium salt concentration 1.8mol / L, and then add 1,4-butane sultone to get it. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com