A method of degumming after high-energy ion implantation

An ion implantation, high-energy technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as adverse effects on devices, affect device performance, and difficult to remove, reduce wafer surface defects, and improve product quality. rate, the effect of reducing the generation of residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

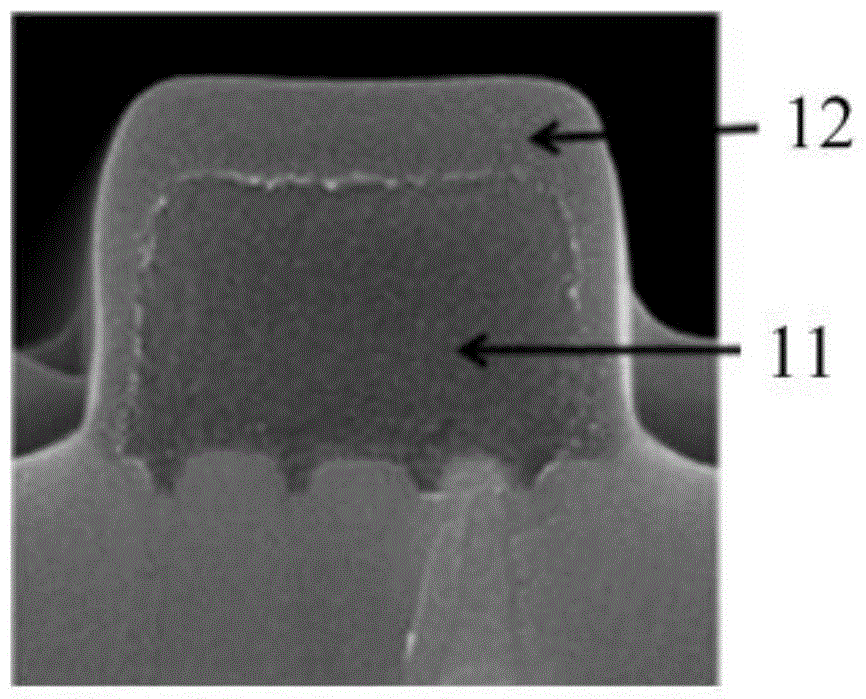

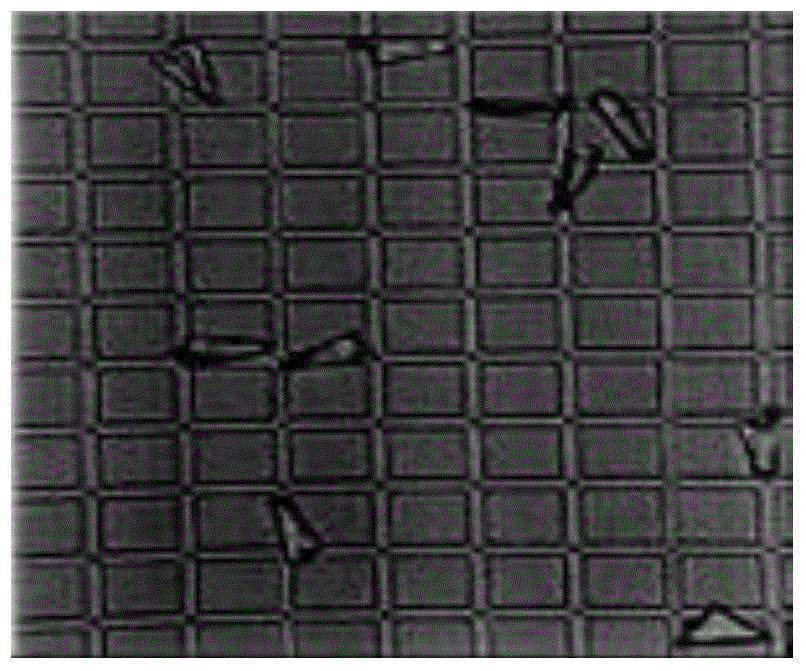

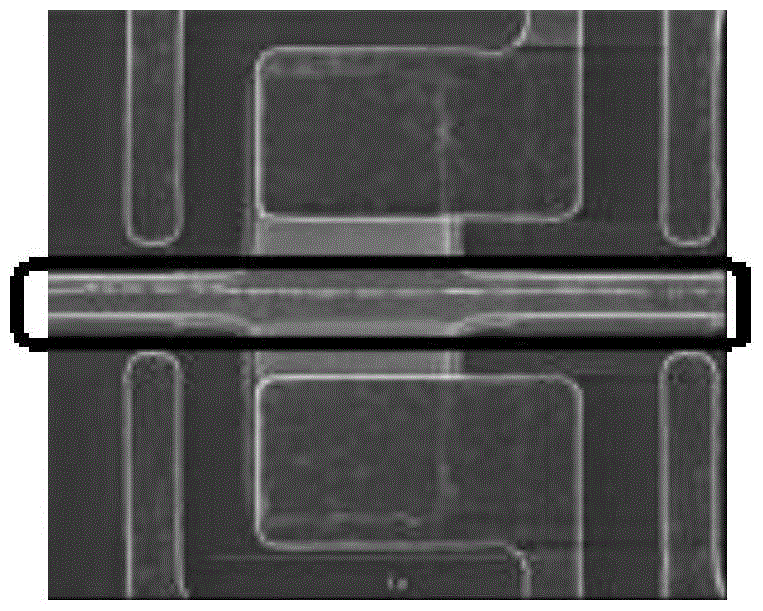

[0032] The core idea of the present invention is to propose a degumming method after high-energy ion implantation, which adopts three stages of degumming, the first stage is the wafer preheating stage, and the process temperature required for subsequent reactions is reached; the second stage It is the surface hard shell removal stage, using pure hydrogen and nitrogen mixed gas as the process gas to remove the surface carbonized hard shell after high-energy ion implantation; the third stage is the main photoresist removal stage, mixed with a certain proportion of oxygen, hydrogen, nitrogen Gas is the process gas to remove residual photoresist. The degumming method of the three-stage process of the present invention utilizes the principle of hydrogen to reduce the cross-linked carbon chain, and removes the carbonized hard shell on the outer surface of the photoresist after injection under mild reaction conditions, thereby avoiding the excessive degumming rate at the beginning o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com