Method for fabricating patterned sapphire substrate by nanoimprint technology without residual layer

A patterned sapphire and nano-imprinting technology, which is applied in the direction of optomechanical equipment, photo-plate making process of pattern surface, optics, etc., can solve the problems of nano-imprinting residual layer, etc., and achieve industrialization, short process, and pattern resolution high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

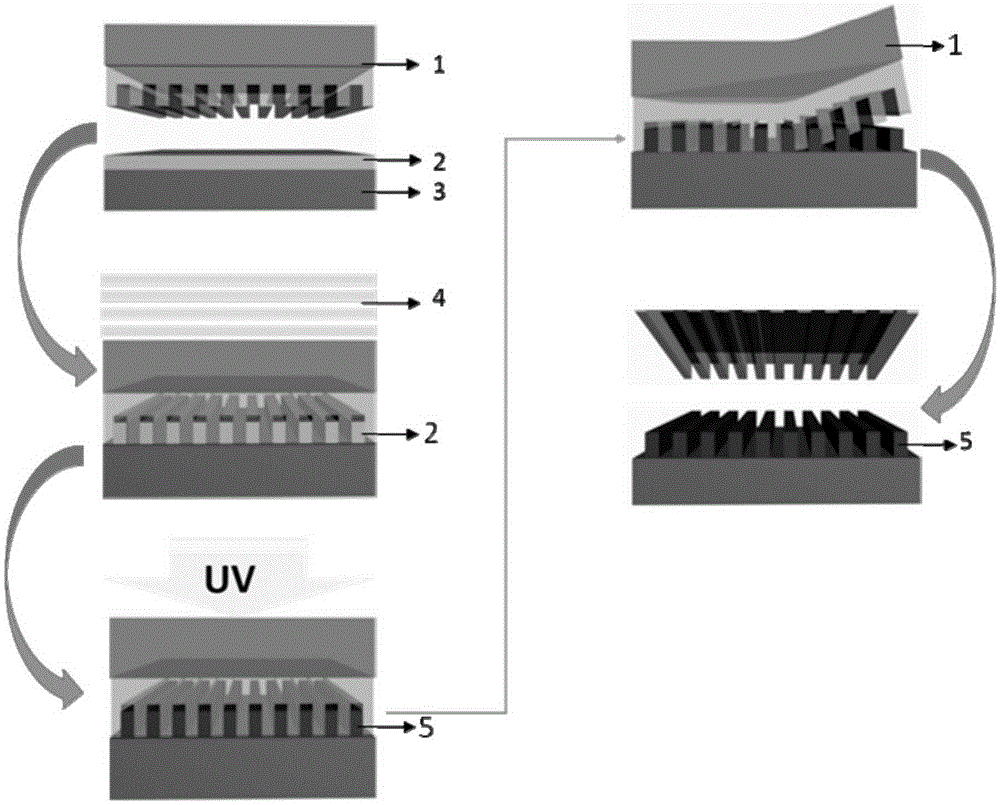

Method used

Image

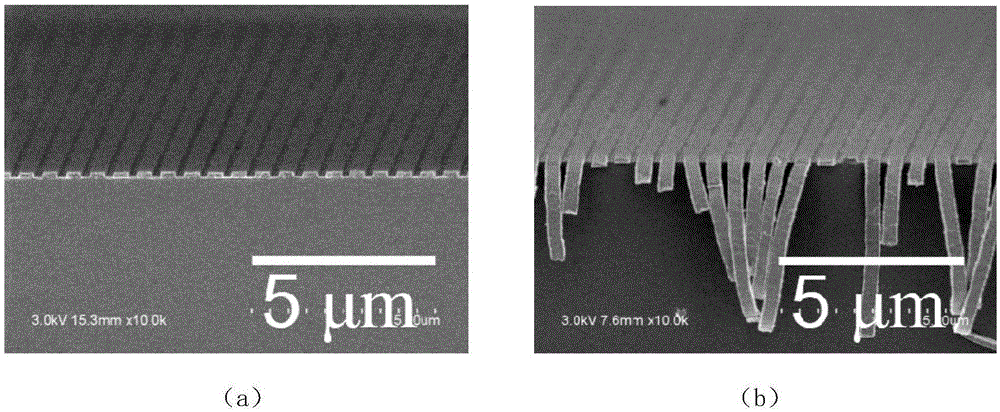

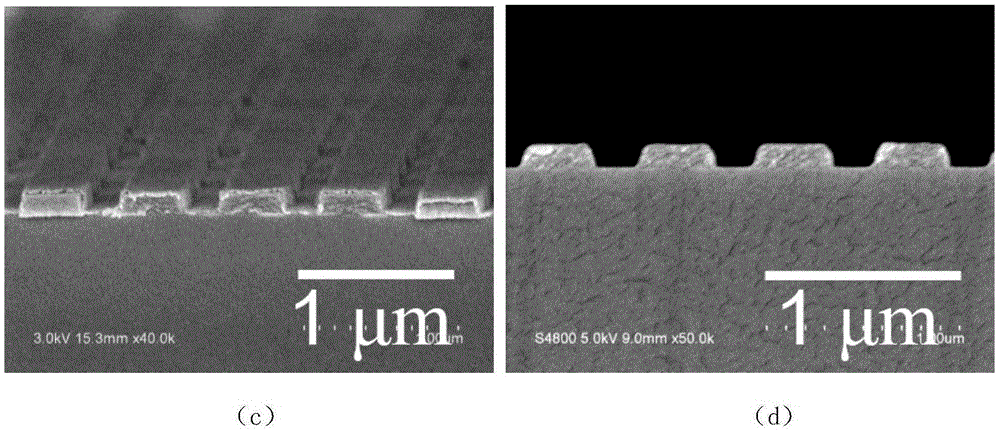

Examples

specific Embodiment approach

[0024] (1) Anti-adhesive treatment of composite formwork

[0025] Select a grating composite template with a period of 550nm and a depth of 110nm, and perform oxygen plasma treatment on the surface of the composite template for a very short time, so that a very thin layer of silicon dioxide is formed on the surface of the rigid structure layer, and then passed through the anti-adhesive agent in the vacuum desiccator Anti-adhesive treatment of composite formwork by gasification method.

[0026] (2) Selection and control of embossing film thickness

[0027] For the calculation of the duty cycle of the composite template, the depth of the template used is 110nm, the duty ratio is 1:1, the film thickness of the suitable imprinting glue is 55nm, the experimental control film thickness is between 50nm-55nm, and BYK3570 ultraviolet light is selected Take curing glue as an example, the concentration of the glue used is 2%, the speed of glue application is 3000rpm, the time of glue ap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com