Non-aqueous electrolyte for high-voltage lithium ion batteries

A lithium-ion battery, non-aqueous electrolyte technology, applied in non-aqueous electrolytes, electrolytes, secondary batteries, etc., can solve the problems of cycle performance degradation, battery leakage, battery pressure and temperature rise, etc., to improve the flame retardant effect , prevent battery abuse, improve the effect of flash point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

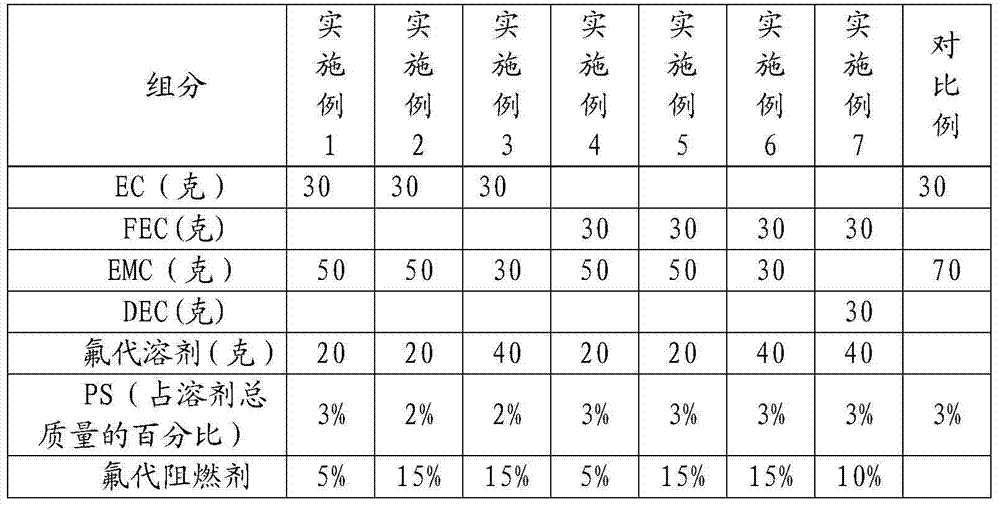

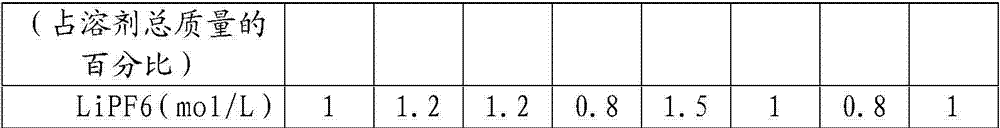

Embodiment 1

[0026] The electrolyte is prepared in the BRAUN glove box, which is filled with nitrogen with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is at room temperature. Mix 30 grams of EC, 50 grams of EMC, and 20 grams of 1,1,2,2-tetrafluoroethyl-2,2,2-trifluoroethyl ether evenly, seal it, and put it in the refrigerator until it cools down to 8°C After that, transfer to the glove box, then add LiPF6 in two batches and fully mix to form the non-aqueous electrolyte of the lithium-ion battery whose molar concentration of lithium salt is 1mol / L, and add 5% of the total mass of the solvent to the above non-aqueous electrolyte. Tris(1,1,1,3,3,3-hexafluoroisopropyl) phosphate (self-made), uniformly mixed and added with 3% of the total mass of solvent PS, evenly mixed to obtain a high-voltage lithium-ion non-aqueous electrolyte.

[0027] The preparation method of tris (1,1,1,3,3,3-hexafluoroisopropyl) phosphate:

[0028] Mix and stir 500 mi...

Embodiment 2

[0030]The electrolyte is prepared in the BRAUN glove box, which is filled with nitrogen with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is at room temperature. Mix 30 grams of EC, 50 grams of EMC and 20 grams of difluoromethyl-2,2,2-trifluoroethyl ether, mix well, seal it and put it in the refrigerator until it cools down to 8°C, then transfer it to the glove box , and then add LiPF6 in two batches and mix thoroughly to form a non-aqueous electrolyte solution for a lithium-ion battery with a molar concentration of lithium salt of 1.2mol / L. Add tris(2,2, 2-trifluoroethyl) phosphite (CAS: 358-63-4, purchased from Alfa Aisha Chemical Co., Ltd.), uniformly mixed, adding 3% of the total mass of solvent PS and uniformly mixed to obtain a high-voltage lithium ion water electrolyte.

Embodiment 3

[0032] The electrolyte is prepared in the BRAUN glove box, which is filled with nitrogen with a purity of 99.999%, the moisture in the glove box is controlled at ≤5ppm, and the temperature is at room temperature. Mix 30 grams of EC, 30 grams of EMC and 40 grams of 1,1,2,2-tetrafluoroethyl-2,2,3,3-tetrafluoropropyl ether, mix well, seal it and put it in the refrigerator until it cools After reaching 8°C, transfer it to a glove box, then add LiPF6 in two batches and mix thoroughly to form a non-aqueous electrolyte solution for a high-voltage battery with a lithium salt molar concentration of 1.2mol / L. Add a total of solvents to the above non-aqueous electrolyte Tris(2,2,2-trifluoroethyl) phosphite (CAS: 358-63-4, purchased from Alfa Aisha Chemical Co., Ltd.) with 15% mass, mixed evenly, and 3% total mass of solvent was added The PS is evenly mixed to obtain a high-voltage lithium-ion non-aqueous electrolyte.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com