Method for increasing protein adsorption capacity and adsorption rate by using high-density polyethylenimine (PEI) modified medium

A polyethyleneimine, high-density technology, applied in the field of protein chromatographic separation, can solve the problems of high price of dextran, high cost of medium synthesis, complex synthesis process, etc., and achieves low price, high adsorption rate, and biocompatibility. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Take 1g Sepharose FF (average particle size 90μm) drained from the G3 funnel and put it into a 50mL Erlenmeyer flask. Add 2mL dimethyl sulfoxide, 1mL epichlorohydrin, and 2mL NaOH (1mol / L). 25℃, 170rpm shaker reaction for 2.5h, rinse repeatedly with deionized water until the cleaning solution is phenolphthalein-Na 2 S 2 O 3 Solution detection does not change color, and an activation medium with active epoxy groups on the surface is prepared. The epoxy modification density of the activation medium is 60mmol / L.

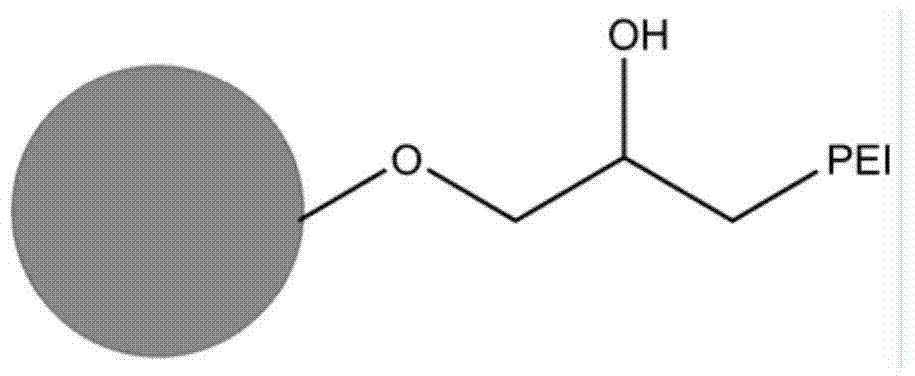

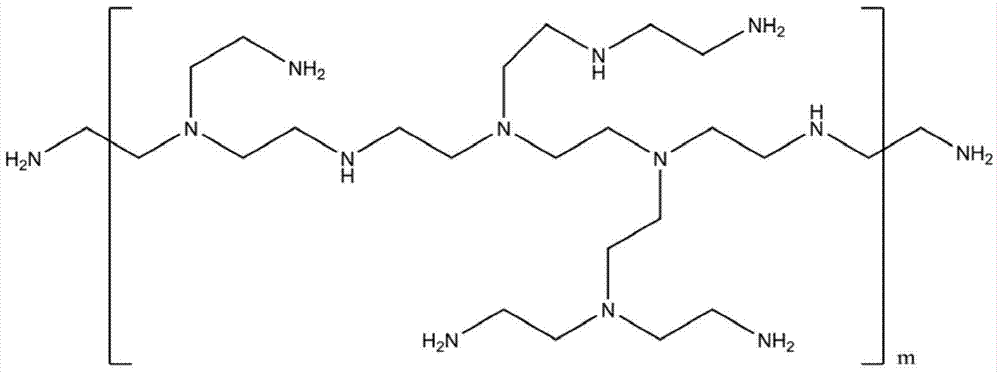

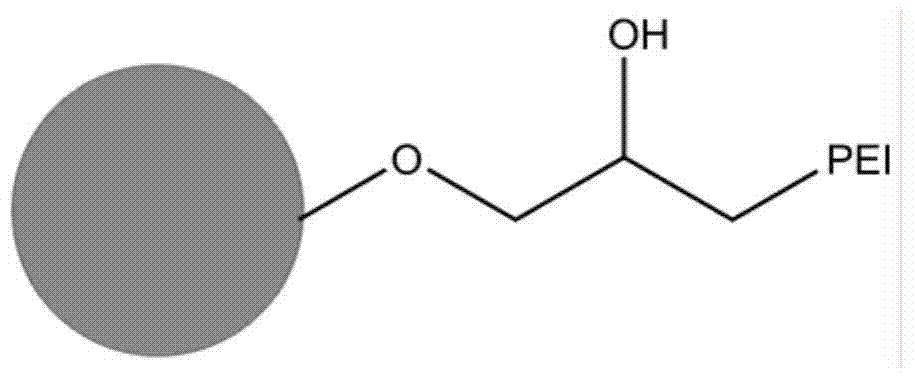

[0025] Add 1mL of PEI (MW1200Da) aqueous solution (25%w / w) to the activation medium (1g), 25℃, 170rpm, 4h, so that PEI can fully diffuse into the medium pores, add 0.5mL NaOH (2mol / L) , 25℃, 170rpm reaction for 48h to couple PEI to agarose, rinse repeatedly with deionized water, until the cleaning solution is detected with phenolphthalein and do not change color, then put the medium in 0.5g / L sodium borohydride solution at room temperature After 12 hours of reactio...

Embodiment 2

[0027] Add 1g of the activation medium in Example 1 drained with a G3 funnel to 1mL of PEI (MW750000Da) aqueous solution (6%w / w), 25℃, 170rpm, 4h, so that PEI can fully diffuse into the pores of the medium, add 1mL of NaOH (1mol / L), 25℃, 170rpm for 48h to couple PEI to agarose, rinse repeatedly with deionized water until the cleaning solution is detected by phenolphthalein and do not change color, and then put the medium at 0.5g / L In the sodium borohydride solution, the residual epoxy group on the surface of the reduction medium was reacted at room temperature for 12 hours, and the ion exchange capacity of the prepared medium was 520 mmol / L by repeated washing with deionized water.

Embodiment 3

[0029] Add 1g of the activation medium in Example 1 drained with a G3 funnel to 1mL of PEI (MW750000Da) aqueous solution (12%w / w), 25℃, 170rpm, 8h, so that PEI can fully diffuse into the medium pores, add 1mL of NaOH (1mol / L), 25℃, 170rpm for 48h to couple PEI to agarose, rinse repeatedly with deionized water until the cleaning solution is detected by phenolphthalein and do not change color, and then put the medium at 0.5g / L In the sodium borohydride solution, the residual epoxy groups on the surface of the reduction medium were reacted at room temperature for 12 hours, and the ion exchange capacity of the prepared medium was 740 mmol / L by repeated washing with deionized water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com