Material CdS/Ba0.4Sr0.6TiO3 for producing hydrogen by photocatalytically decomposing water and preparation method thereof

A technology for photocatalysis and water splitting, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as easy recombination of photogenerated electrons and holes, low utilization rate of visible light, harsh preparation conditions, etc. , to achieve the effect of easy reuse, low production cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

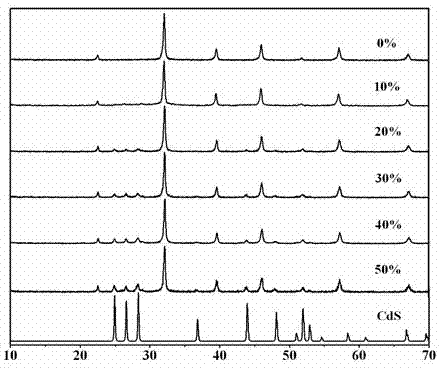

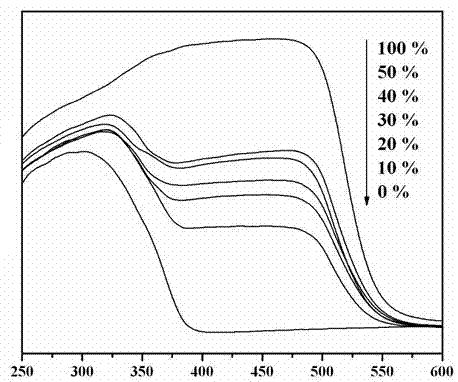

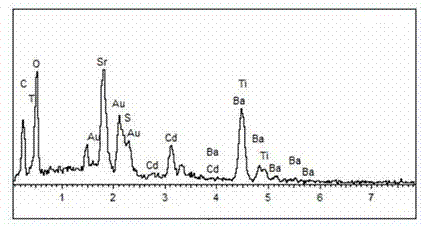

[0014] Synthesis of catalyst material of the present invention:

[0015] Disperse 4 mmol (1.0454 g) of barium nitrate and 6 mmol (1.2698 g) of strontium nitrate in 25 ml of 2 mol / L sodium hydroxide solution, and stir for 30 minutes to obtain A solution. Then 10 mmol (3.4 mL) of tetra-n-butyl titanate was dissolved in 5 mL of absolute ethanol, and stirred evenly to obtain B solution. Solution B was poured into solution A stirred in an ice-water bath, and solution C was obtained after stirring for 30 minutes. Dissolve 4 mmol (1.0661 g) of cadmium acetate in 5 mL of deionized water, slowly add it dropwise to solution C, and obtain solution D after ultrasonic dispersion for 15 minutes. Dissolve 4 mmol (0.9607 g) of sodium sulfide in 5 ml of deionized water, slowly add it dropwise to solution D, and ultrasonically disperse for 15 minutes. The above solution was put into a 100 ml polytetrafluoroethylene reaction kettle, and put into a muffle furnace at 200° C. for hydrothermal rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com