Visible light response AgCl-Ag-Ag2CO3 composite photocatalyst, and preparation method and application thereof

A technology of catalyst and composite light, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of reduced photocatalytic activity and poor photostability, and achieves simple operation, low cost, and excellent performance. Effect of Visible Light Degradation Activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Step 1, take 20ml of Changbaishan hot spring water and stir at room temperature;

[0021]Step 2, add 20 ml of 0.01 mol / L AgNO dropwise to the above solution with a constant pressure funnel 3 solution;

[0022] Step 3, after the dropwise addition, continue to stir for 1 hour to make the crystallization complete;

[0023] Step 4, the obtained product is centrifuged and washed with deionized water, and then dried to obtain AgCl-Ag-Ag 2 CO 3 .

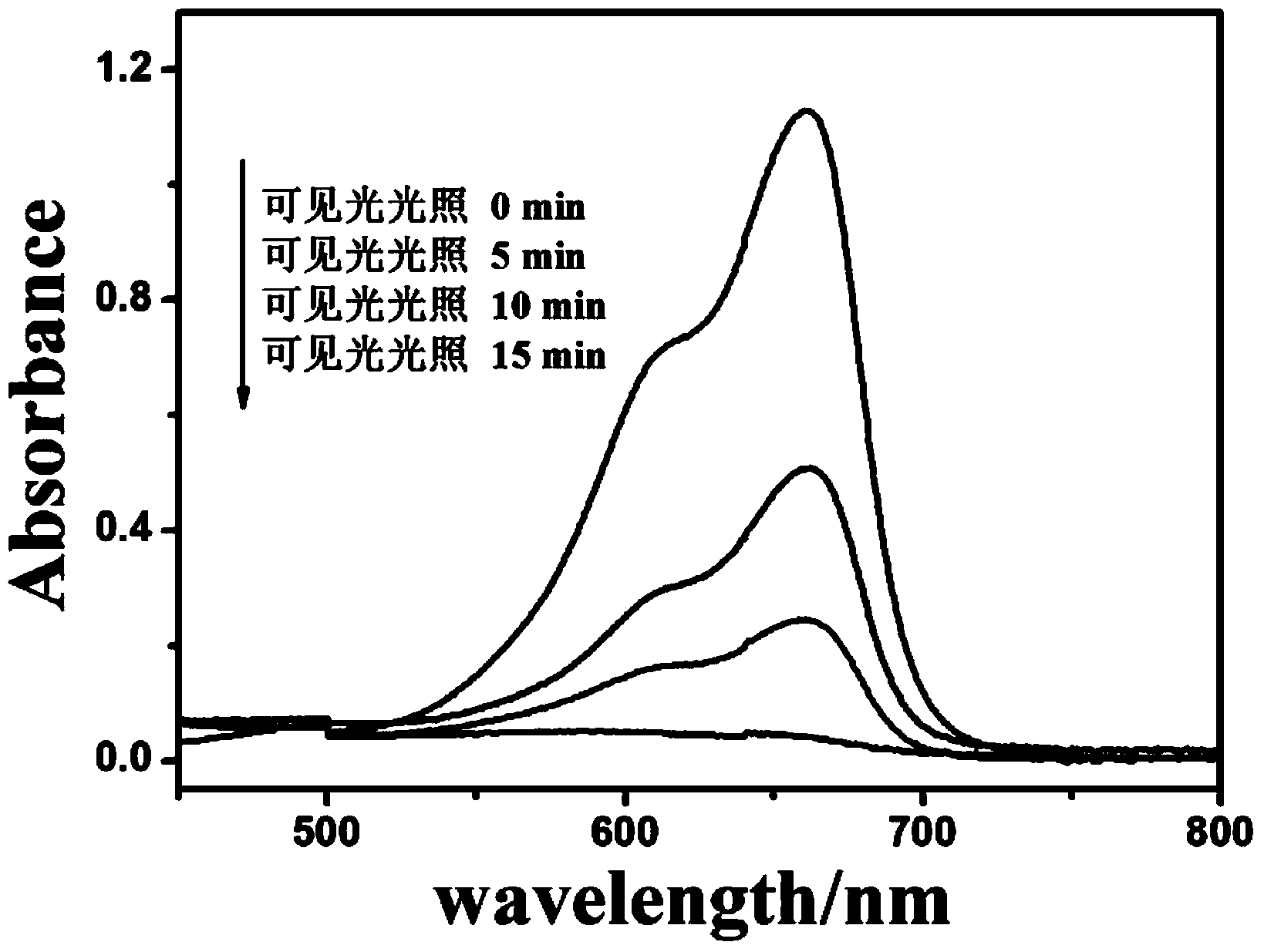

[0024] AgCl-Ag-Ag 2 CO 3 The photocatalytic application of the composite photocatalyst is: 0.01 gram of AgCl-Ag-Ag 2 CO 3 The powder was dispersed in 20 ml of 10 mg / L methylene blue solution, and the methylene blue was photocatalytically degraded under visible light irradiation; the light source used was a 300W xenon lamp equipped with a 400nm filter.

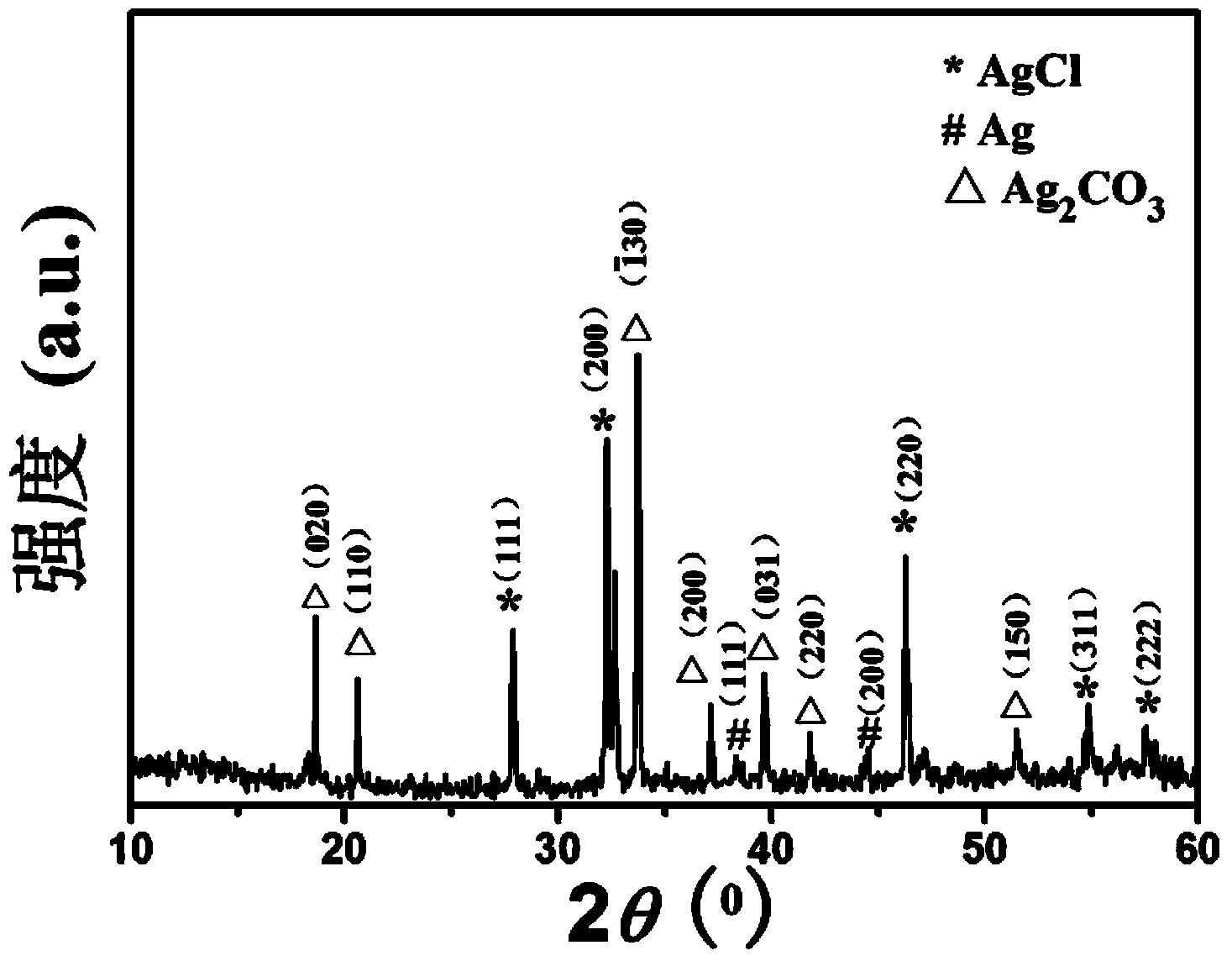

[0025] The prepared AgCl-Ag-Ag 2 CO 3 The mass fraction of AgCl in the composite photocatalyst is 39%, the mass fraction of Ag is 14%, and the Ag 2 CO 3 The quality score...

Embodiment 2

[0028] Step 1, take 100ml of Changbai hot spring water and stir at room temperature;

[0029] Step 2, add 15 ml of 0.05 mol / L AgNO dropwise to the above solution with a constant pressure funnel 3 solution;

[0030] Step 3, after the dropwise addition, continue to stir for 1 hour to make the crystallization complete;

[0031] Step 4, the obtained product is centrifuged and washed with deionized water, and then dried to obtain AgCl-Ag-Ag 2 CO 3 .

[0032] AgCl-Ag-Ag 2 CO 3 The photocatalytic application of the composite photocatalyst is the same as in Example 1.

[0033] The prepared AgCl-Ag-Ag 2 CO 3 The mass fraction of AgCl in the composite photocatalyst is 60%, the mass fraction of Ag is 15%, and the Ag 2 CO 3 The mass fraction is 25%.

Embodiment 3

[0035] Step 1, take 50ml of Yunnan Atami hot spring water and stir at room temperature;

[0036] Step 2, add 15 ml of 0.1 mol / L AgNO dropwise to the above solution with a constant pressure funnel 3 solution;

[0037] Step 3, after the dropwise addition, continue to stir for 1 hour to make the crystallization complete;

[0038] Step 4, the obtained product is centrifuged and washed with deionized water, and then dried to obtain AgCl-Ag-Ag 2 CO 3 .

[0039] AgCl-Ag-Ag 2 CO 3 The photocatalytic application of the composite photocatalyst is the same as in Example 1.

[0040] The prepared AgCl-Ag-Ag 2 CO 3 The mass fraction of AgCl in the composite photocatalyst is 30%, the mass fraction of Ag is 5%, and the Ag 2 CO 3 The quality score is 65%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com