Method for synthesizing ethyl 3-n-butyl amino propionate

A technology for ethyl n-butylaminopropionate and a synthesis method, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., and can solve the synthesis of ethyl 3-n-butylaminopropionate, an intermediate of repellent esters. Long time, small environmental pollution, low cost and other problems, to achieve the effect of good solubility, reduced reaction time, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

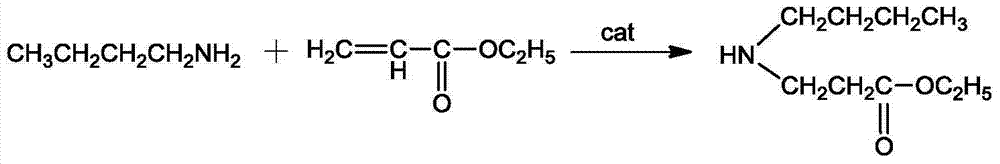

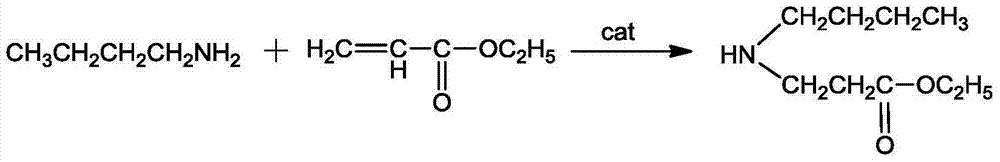

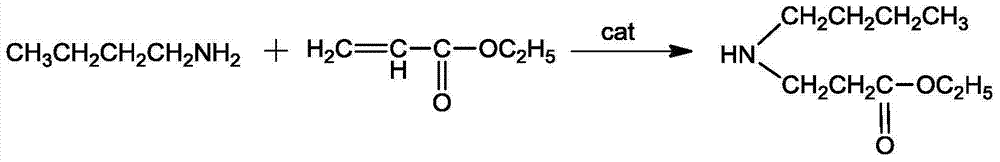

[0017] A kind of synthetic method of 3-n-butylaminopropionate ethyl ester, select n-butylamine and ethyl acrylate to react and prepare 3-n-butylaminopropionate ethyl ester, reaction formula is as follows:

[0018]

[0019] The specific reaction steps are as follows: add n-butylamine and catalyst cerium nitrate in a 500mL four-necked bottle with a stirring device, a reflux device, a thermometer and a constant pressure dropping funnel; Add ethyl acrylate dropwise under conditions, after the dropwise addition, continue to stir and keep warm for 4h; wherein the mol ratio of n-butylamine to ethyl acrylate is 4:1, and the amount of cerium nitrate added is 10% of the molar number of ethyl acrylate; After the reaction was finished, excess n-butylamine was distilled off under atmospheric pressure, and then fractionated under controlled pressure at 0.67KPa to obtain ethyl 3-n-butylaminopropionate with a yield of 92.6%, a purity of 99.6%, and a reaction time of 5 hours.

Embodiment 2

[0021] A kind of synthetic method of 3-n-butylaminopropionate ethyl ester, select n-butylamine and ethyl acrylate to react and prepare 3-n-butylaminopropionate ethyl ester, reaction formula is as follows:

[0022]

[0023] The specific reaction steps are as follows: add n-butylamine and catalyst cerium nitrate in the 500mL four-necked bottle with stirring device, reflux device, thermometer and constant pressure dropping funnel; Add ethyl acrylate dropwise under conditions, after the dropwise addition, continue to stir and keep warm for 8 hours; wherein the mol ratio of n-butylamine to ethyl acrylate is 3:1, and the amount of cerium nitrate added is 10% of the molar number of ethyl acrylate; After the reaction was finished, excess n-butylamine was distilled off under atmospheric pressure, and then fractionated under controlled pressure at 1.33KPa to obtain ethyl 3-n-butylaminopropionate with a yield of 93.8%, a purity of 99.7%, and a reaction time of 5 hours.

Embodiment 3

[0025] A kind of synthetic method of 3-n-butylaminopropionate ethyl ester, select n-butylamine and ethyl acrylate to react and prepare 3-n-butylaminopropionate ethyl ester, reaction formula is as follows:

[0026]

[0027] The specific reaction steps are as follows: add n-butylamine and catalyst cerium nitrate in a 500mL four-necked bottle with stirring device, reflux device, thermometer and constant pressure dropping funnel; Add ethyl acrylate dropwise under conditions, after the dropwise addition, continue to stir and keep warm for 6 hours; wherein the mol ratio of n-butylamine to ethyl acrylate is 5:1, and the amount of cerium nitrate added is 10% of the molar number of ethyl acrylate; After the reaction was finished, excess n-butylamine was distilled off under atmospheric pressure, and then fractionated under controlled pressure at 1.0 KPa to obtain ethyl 3-n-butylaminopropionate with a yield of 93.2%, a purity of 99.6%, and a reaction time of 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com