Preparation method of halogen-free low-temperature flame-retardant fiber

A flame-retardant fiber and low-temperature technology, which is applied in the field of preparation of self-assembled low-temperature flame-retardant fibers at room temperature, can solve the problems of high flame-retardant temperature of flame retardants, achieve high enthalpy, reduce smoke release, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific implementation mode 1: The preparation method of halogen-free low-temperature flame-retardant fiber in this implementation mode is as follows:

[0014] 1. Preparation of titanyl sulfate mixed solution: pour titanyl sulfate into sulfuric acid solution, and stir at 0-20°C for 1-60 minutes to obtain titanyl sulfate mixed solution, the concentration of titanyl sulfate in titanyl sulfate mixed solution 1~100g / L, the concentration of sulfuric acid is 5~100ml / L;

[0015] Two, according to the ratio of Ti ion, Cu ion, Ca ion molar ratio 1~10:1:1, calcium nitrate solution is added in the titanyl sulfate mixed solution, stir well, add copper sulfate solution, stir 1~30min, obtain Mixed solution, the concentration of the calcium nitrate solution is 1-100g / L, and the concentration of the copper sulfate solution is 1-80g / L;

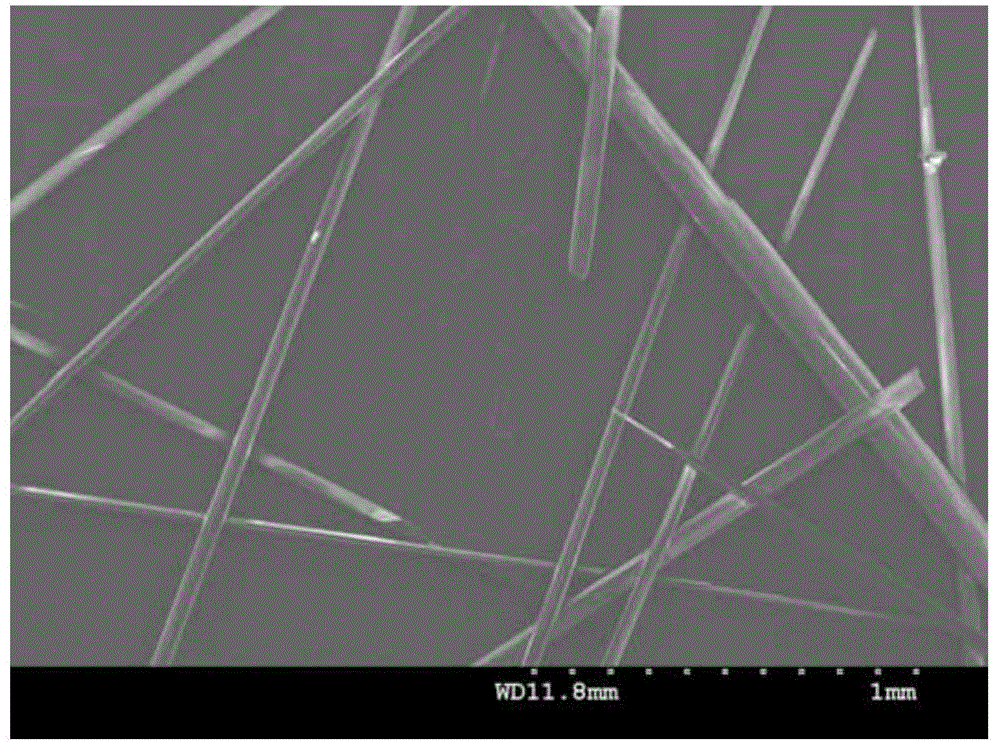

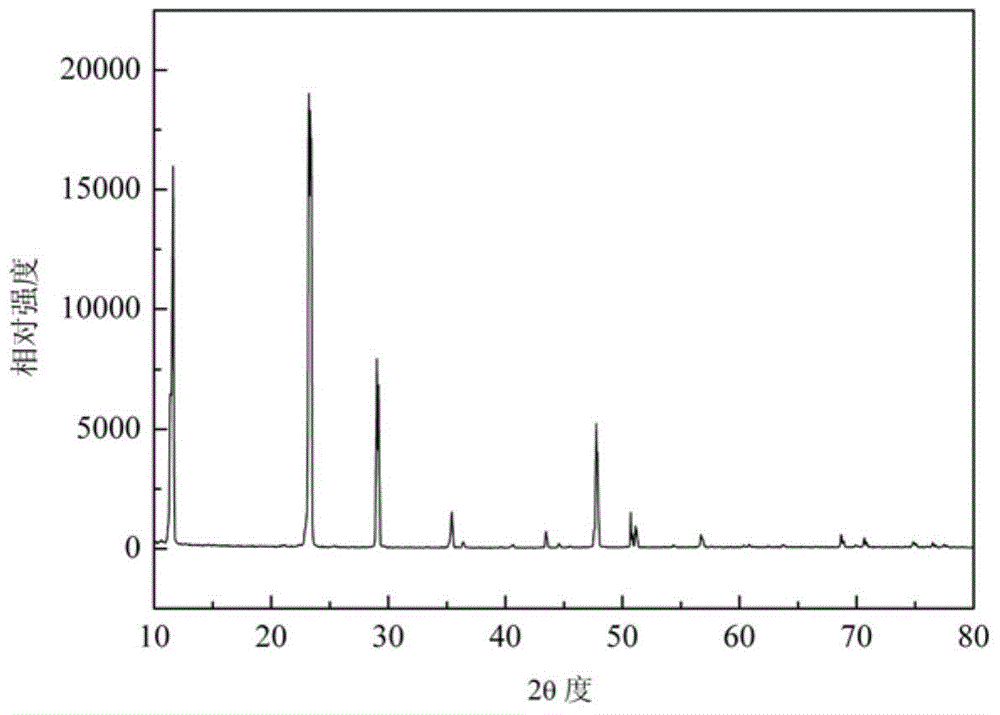

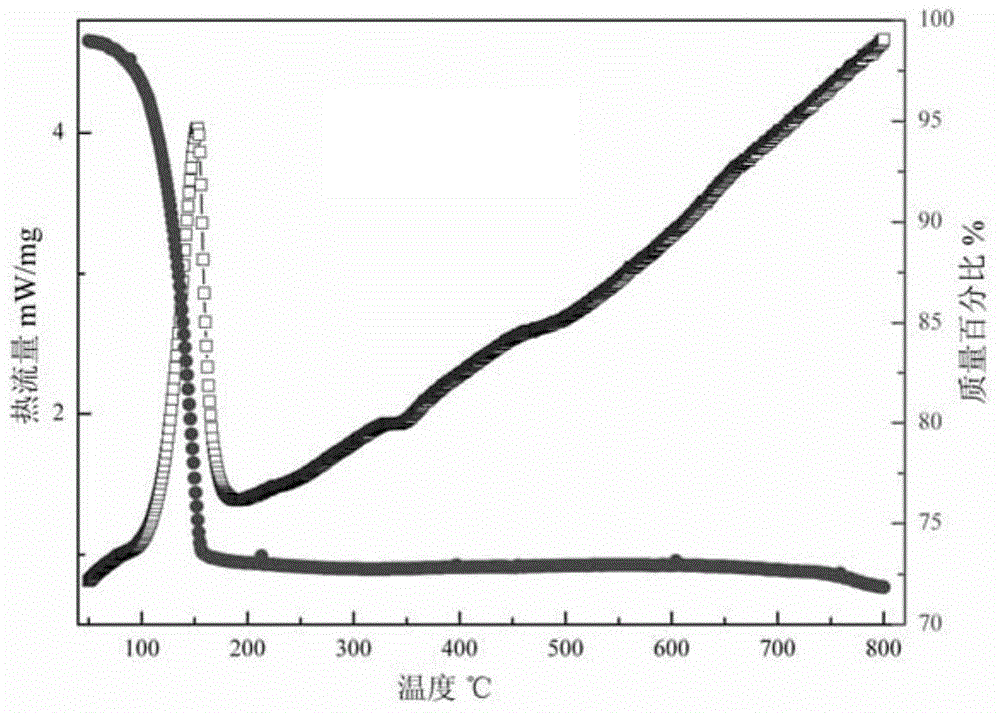

[0016] 3. Seal the mixed solution obtained in step 2, let it stand for 1-600 hours, filter it, wash it with water for 3-7 times, and then dry it at 4...

specific Embodiment approach 2

[0017] Embodiment 2: This embodiment differs from Embodiment 1 in that the concentration of titanyl sulfate in the titanyl sulfate mixed solution in step 1 is 5-60 g / L, and the concentration of sulfuric acid is 10-80 ml / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the concentration of titanyl sulfate in the titanyl sulfate mixed solution in step 1 is 15 g / L, and the concentration of sulfuric acid is 20 ml / L. Others are different from the first or second specific embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com