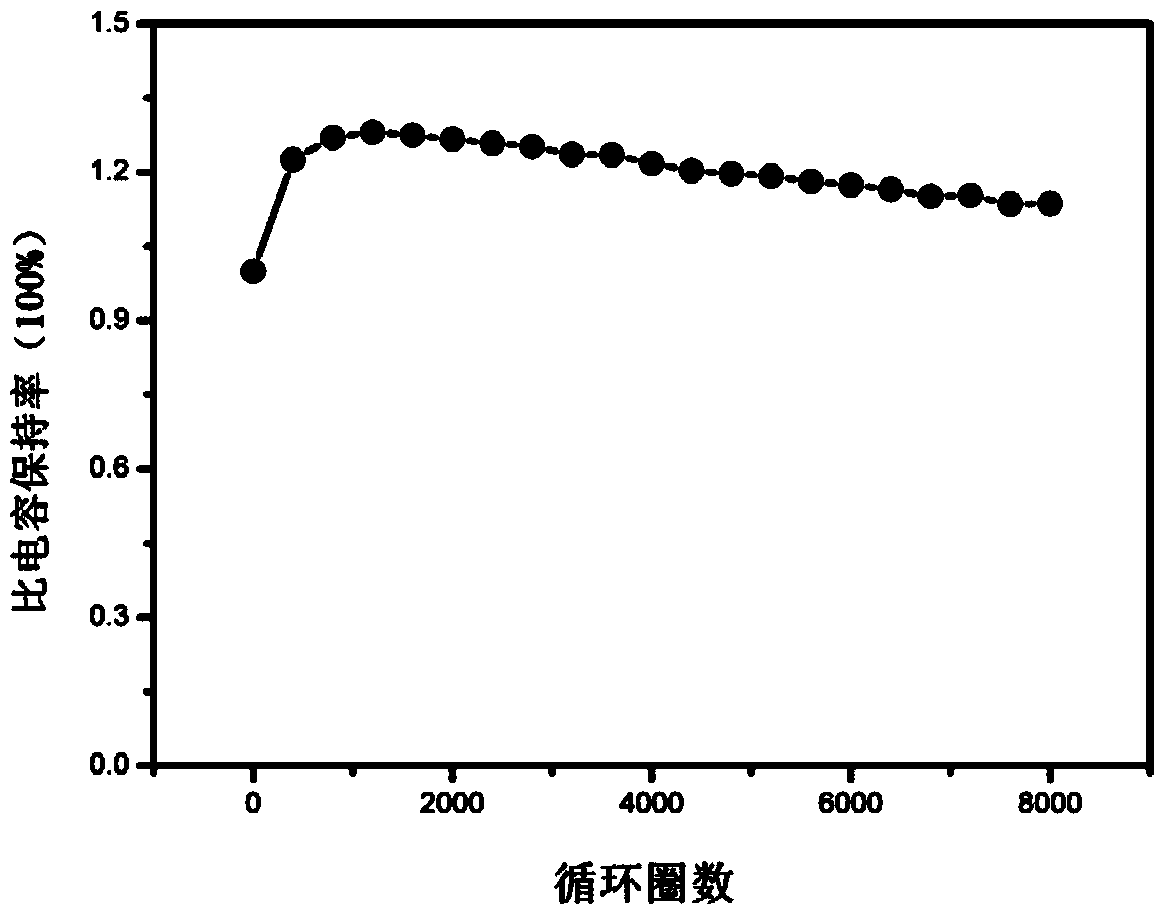

Method for preparing porous NiCo2O4/MnO2 nuclear shell nanowire array supercapacitor electrode material

A nanowire array, supercapacitor technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, nanotechnology, etc. The problem is that the preparation method is simple, the supercapacitor performance is good, and the low conductivity is solved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Put nickel foam of appropriate size into a solution containing 1M hydrochloric acid for ultrasonic cleaning, the purpose is to remove nickel oxide on the surface of nickel foam.

[0028] (2) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and urea were dissolved in water and stirred to obtain a mixed solution in which Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The molar amounts of O are 0.1 mmol and 0.2 mmol, respectively, and the amount of urea is 0.05 g.

[0029] (3) Pour the above mixed solution into the polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, and put in a piece of cleaned foam nickel with a size of 1*4cm, and put the hydrothermal reaction kettle Put it into a blast drying oven, react under hydrothermal conditions at 120° C. for 6 hours, and then cool the reaction kettle to room temperature.

[0030] (4) Take out the pink nickel foam,...

Embodiment 2

[0035] (1) Put nickel foam of appropriate size into a solution containing 1M hydrochloric acid for ultrasonic cleaning, the purpose is to remove nickel oxide on the surface of nickel foam.

[0036] (2) Weigh the raw material nickel nitrate hexahydrate (Ni(NO 3 ) 2 ·6H 2 O), cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 O) and urea were dissolved in water and stirred to obtain a mixed solution in which Ni(NO 3 ) 2 ·6H 2 O and Co(NO 3 ) 2 ·6H 2 The molar amounts of O are 0.1 mmol and 0.2 mmol, respectively, and the amount of urea is 2 g.

[0037] (3) Pour the above mixed solution into the polytetrafluoroethylene hydrothermal reaction kettle, keep the filling degree of 80%, and put in a piece of cleaned foam nickel, the size of which is 1*4cm, and put the hydrothermal reaction kettle Put it into a blast drying oven, react under hydrothermal conditions at 90°C for 6 hours, and then cool the reaction kettle to room temperature.

[0038] (4) Take out the pink nickel foam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com