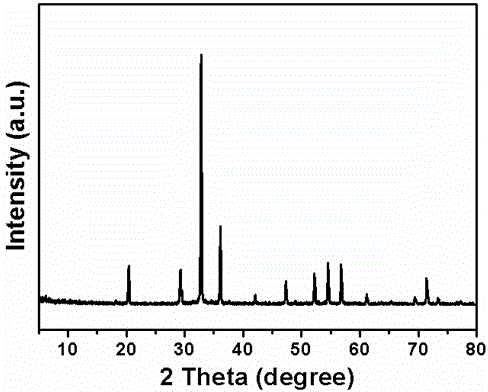

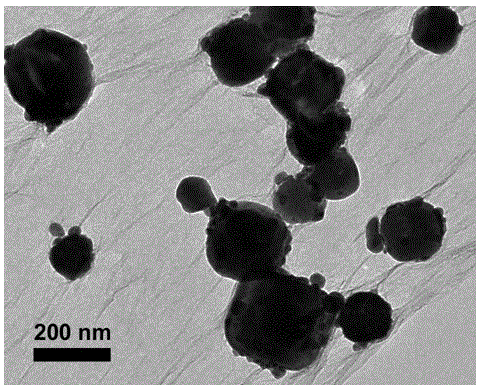

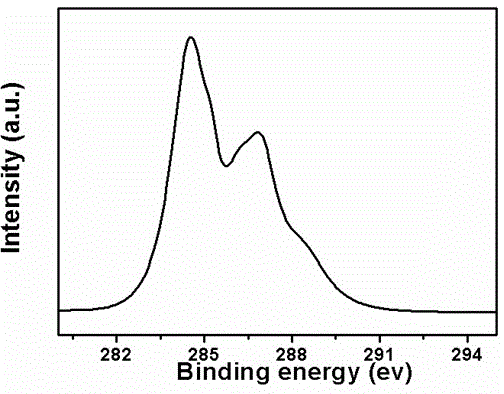

Preparation method of silver phosphate/graphene nanocomposite

A nanocomposite material, graphene technology, applied in the field of nanocomposite materials and photocatalysis, can solve problems such as poor stability and low photocatalytic efficiency, and achieve the effects of improving stability, improving photoelectric conversion efficiency, and inhibiting photocorrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Take 25 mg of graphene oxide and dissolve it in 50 ml of deionized water, and obtain a graphene oxide dispersion with a concentration of 0.5 mg / ml after ultrasonic dispersion; weigh 0.0711 g of disodium hydrogen phosphate solid and dissolve it in deionized water, and after ultrasonic dispersion is uniform Obtain a disodium hydrogen phosphate solution with a concentration of 0.01 mol / L; weigh 0.2548 g of silver nitrate solid and dissolve it in the above graphene oxide dispersion, wherein the concentration of silver nitrate is 0.03 mol / L, and obtain a precursor solution after magnetic stirring A. Slowly add 50 ml of the above-mentioned disodium hydrogen phosphate solution to 50 ml of precursor solution A under continuous magnetic stirring and dark conditions. After the addition is completed, the mixed solution is stirred at room temperature for 0.5 hours, After centrifugation, wash with deionized water and absolute ethanol several times, and dry in vacuum; weigh 0.05 g of ...

Embodiment 2

[0021] Take 25 mg of graphene oxide and dissolve it in 50 ml of deionized water, and obtain a graphene oxide dispersion with a concentration of 0.5 mg / ml after ultrasonic dispersion; weigh 0.3555 g of disodium hydrogen phosphate solid and dissolve it in deionized water, and after ultrasonic dispersion is uniform Obtain a disodium hydrogen phosphate solution with a concentration of 0.05 mol / L; weigh 1.274 g of silver nitrate solid and dissolve it in the above graphene oxide dispersion, wherein the concentration of silver nitrate is 0.15 mol / L, and obtain a precursor solution after magnetic stirring A. Slowly add 50 ml of the above-mentioned disodium hydrogen phosphate solution to 50 ml of precursor solution A under continuous magnetic stirring and dark conditions. After the addition is completed, the mixed solution is stirred at room temperature for 1 hour, and the precipitate After centrifugation, wash with deionized water and absolute ethanol several times, and dry in vacuum. ...

Embodiment 3

[0024] Take 25 mg of graphene oxide and dissolve it in 50 ml of deionized water, and obtain a graphene oxide dispersion with a concentration of 0.5 mg / ml after ultrasonic dispersion; weigh 0.7107 g of disodium hydrogen phosphate solid and dissolve it in deionized water, and after ultrasonic dispersion is uniform Obtain a disodium hydrogen phosphate solution with a concentration of 0.1 mol / L; weigh 2.548 g of silver nitrate solid and dissolve it in the above graphene oxide dispersion, wherein the concentration of silver nitrate is 0.3 mol / L, and obtain a precursor solution after magnetic stirring A. Slowly add 50 ml of the above-mentioned disodium hydrogen phosphate solution to 50 ml of precursor solution A under continuous magnetic stirring and dark conditions. After the addition, the mixed solution is stirred at room temperature for 2 hours, and the precipitate After centrifugation, wash with deionized water and absolute ethanol several times, and dry in vacuum; weigh 0.5 g of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com