Preparation method of synthetic graphene

A technology for synthesizing graphite and synthesizing loads, which is applied in the field of graphene, can solve problems such as high cost and complex process, and achieve the effect of reducing energy consumption, reducing reaction temperature, and requiring simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

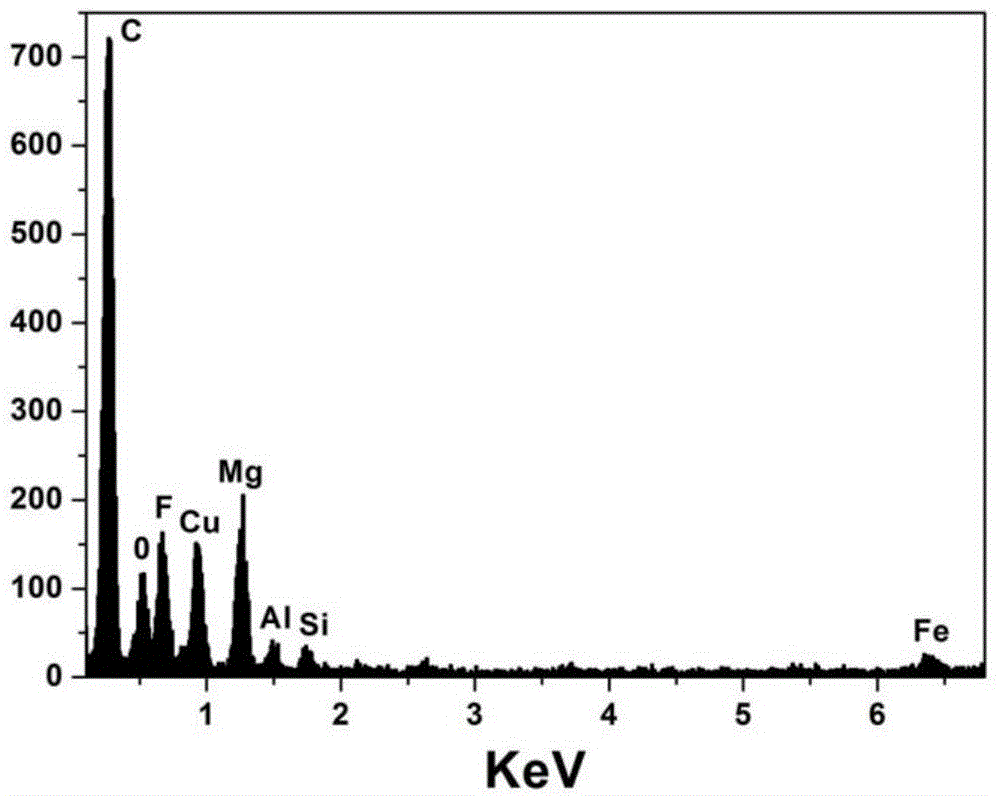

[0034] Place 20 grams of purchased sodium montmorillonite in 0.1mol / L of FeCl 3 The solution was stirred overnight, the purpose is to make the iron ions replace the sodium ions between the clay layers, and obtain the clay that absorbs iron ions between the layers; then centrifuge to discard the supernatant, and place the obtained precipitate in a 0.1mol / L FeCl 3 solution, so circulated 3 times, and finally the centrifuged precipitate was freeze-dried to obtain the loaded Fe 3+ Ionic montmorillonite catalyst.

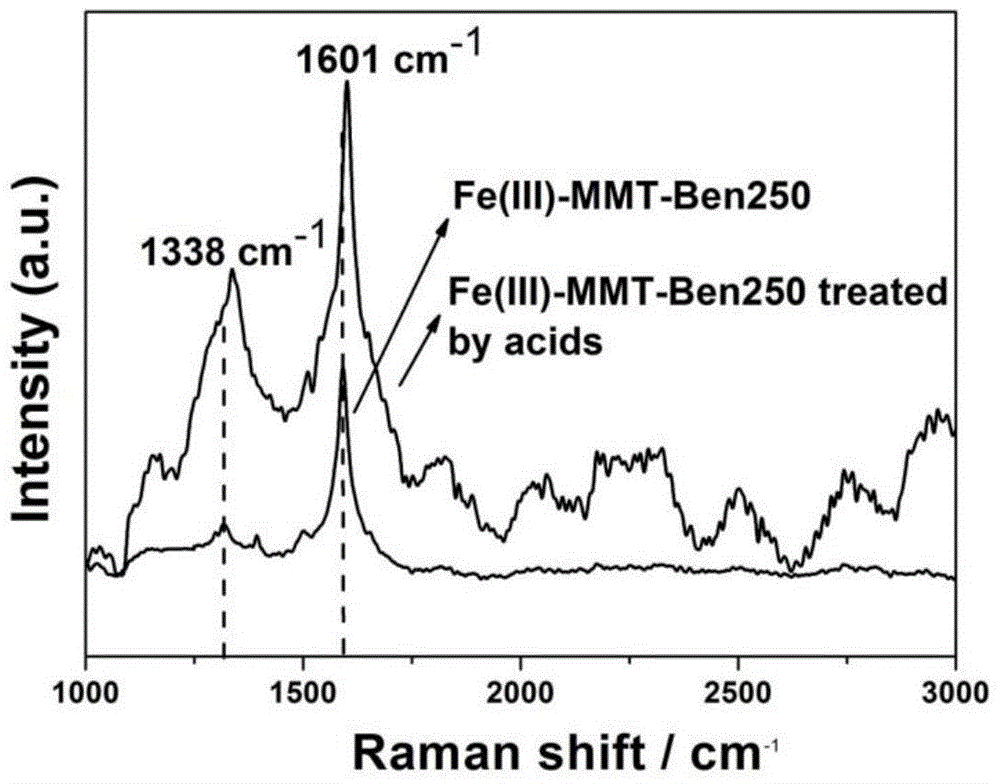

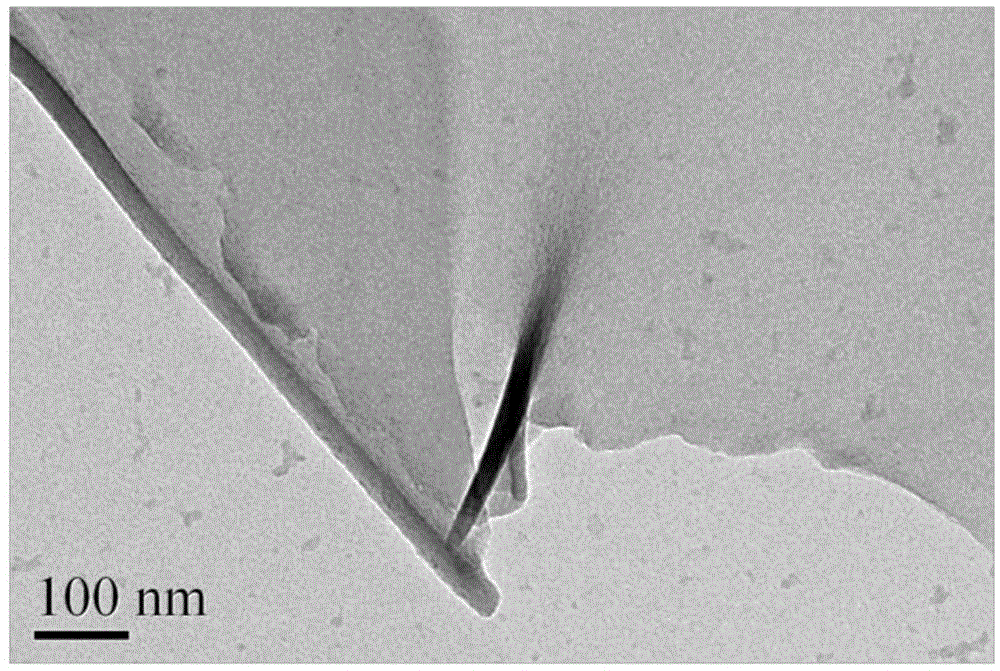

[0035] Will Fe 3+- 0.5g of montmorillonite (yellow) is placed in one crucible, 5ml of benzene solution is placed in another crucible, and then these two crucibles are placed in the reactor of the reactor (the middle and lower part of the reactor has been separated by a steel plate) It is divided into two parts, but the upper end is not sealed, and the gas can diffuse freely in these two parts, the purpose is to allow the benzene vapor volatilized by heating to be abso...

Embodiment 2

[0038] Place 30 grams of purchased sodium montmorillonite in 0.1mol / L of FeCl 3 The solution was stirred overnight, the purpose is to make the iron ions replace the sodium ions between the clay layers, and obtain the clay that absorbs iron ions between the layers; then centrifuge to discard the supernatant, and place the obtained precipitate in a 0.1mol / L FeCl 3 solution, so circulated 3 times, and finally the centrifuged precipitate was freeze-dried to obtain the loaded Fe 3+ Ionic montmorillonite catalyst.

[0039] Will Fe 3+ - 0.5g of montmorillonite (yellow) is placed in one crucible, 5ml of benzene solution is placed in another crucible, and then these two crucibles are placed in the reactor of the reactor (the middle and lower part of the reactor has been separated by a steel plate) It is divided into two parts, but the upper end is not sealed, and the gas can diffuse freely in these two parts, the purpose is to allow the benzene vapor volatilized by heating to be abs...

Embodiment 3

[0041] Place 40 grams of purchased sodium montmorillonite in 0.1mol / L of FeCl 3 The solution was stirred overnight, the purpose is to make the iron ions replace the sodium ions between the clay layers, and obtain the clay that absorbs iron ions between the layers; then centrifuge to discard the supernatant, and place the obtained precipitate in a 0.1mol / L FeCl 3 solution, so circulated 3 times, and finally the centrifuged precipitate was freeze-dried to obtain the loaded Fe 3+ Ionic montmorillonite catalyst.

[0042] Will Fe 3+ - 0.5g of montmorillonite (yellow) is placed in one crucible, 5ml of benzene solution is placed in another crucible, and then these two crucibles are placed in the reactor of the reactor (the middle and lower part of the reactor has been separated by a steel plate) It is divided into two parts, but the upper end is not sealed, and the gas can diffuse freely in these two parts, the purpose is to allow the benzene vapor volatilized by heating to be abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com