Method for exploitation and utilization of polyhalite-halite accompanying mineral deposit

A technology of polyhalite and halite, which is applied in the field of mining and utilization of polyhalite-halite associated deposits, can solve problems such as ineffective utilization, deep burial, and insoluble potassium salt components, etc., so as to reduce mining costs, The effect of high yield, high yield and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

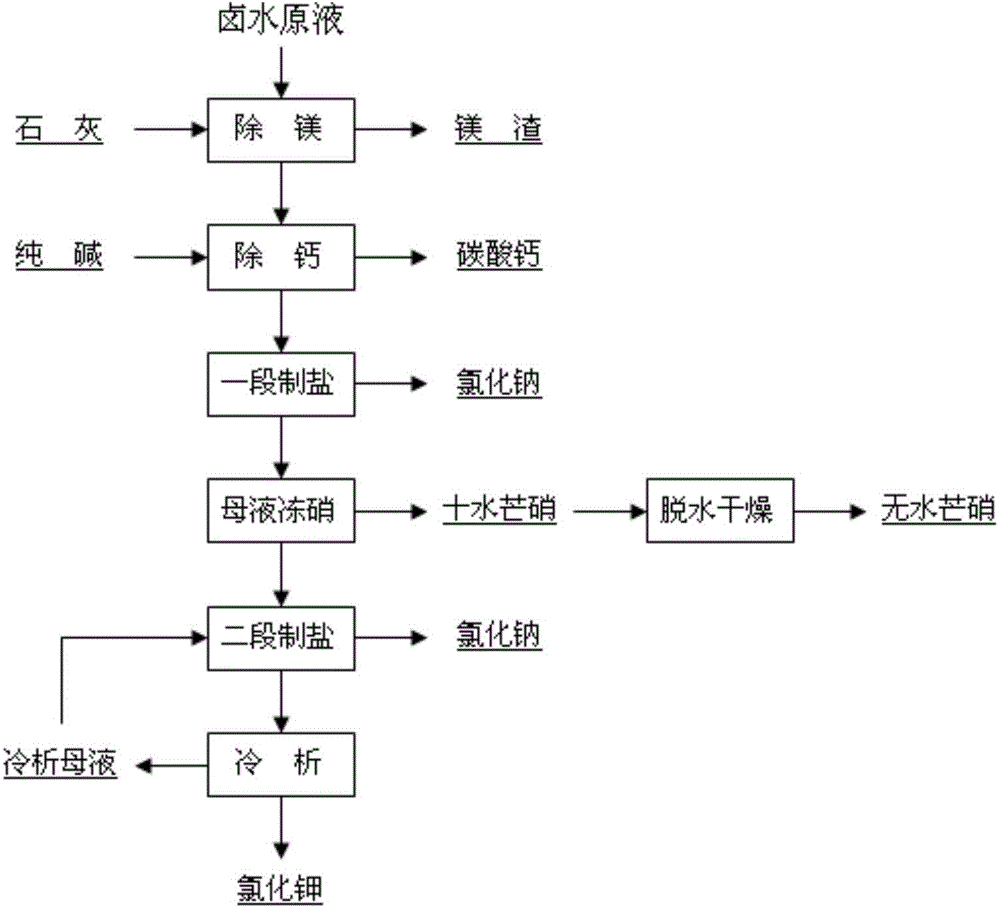

Embodiment 1

[0044] The fresh water is continuously pumped into the inlet end of the polyhalite and halite-associated deposit dissolution well group wells, and at the same time, the dissolved brine is continuously collected from the outlet end. According to the mensuration of sodium ion and potassium ion content in polyhalite and halite associated ore deposit, after obtaining the content of sodium ion and potassium ion, after guaranteeing Na + Under the premise of saturation, the concentration of potassium ions should be increased as much as possible, and the amount of injected water should be calculated according to this principle. After injecting water, control the leaching time for 15 days, at which time the brine Na + Concentration 110g / l, K + Concentration 8g / l. Add 10% lime emulsion made of water under stirring condition to precipitate Mg in brine 2+ , the temperature of the solution during precipitation is 40°C, the pH of the precipitation end point is controlled at 10.0, the pre...

Embodiment 2

[0050] The fresh water is continuously pumped into the inlet end of the polyhalite and halite-associated deposit dissolution well group wells, and at the same time, the dissolved brine is continuously collected from the outlet end. According to the Na in the leaching brine + with K + concentration to determine the injection water flow rate, and control the leaching time for 25 days, at which time the leaching brine Na + Concentration 110g / l, K + Concentration 12g / l. Add 15% lime emulsion made of water under stirring condition to precipitate Mg in brine 2+ , the temperature of the solution during precipitation is 60°C, the pH of the precipitation end point is controlled at 10.4, the precipitation is filtered, and then a sodium carbonate solution with a saturation of 60% is added to the supernatant of the filtered precipitation to precipitate calcium. The molar ratio of the amount of sodium carbonate added to calcium The ratio is 1.5:1, the precipitation temperature is 60°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com