Nano titanium dioxide modification method of electric adsorption desalinization carbon electrode

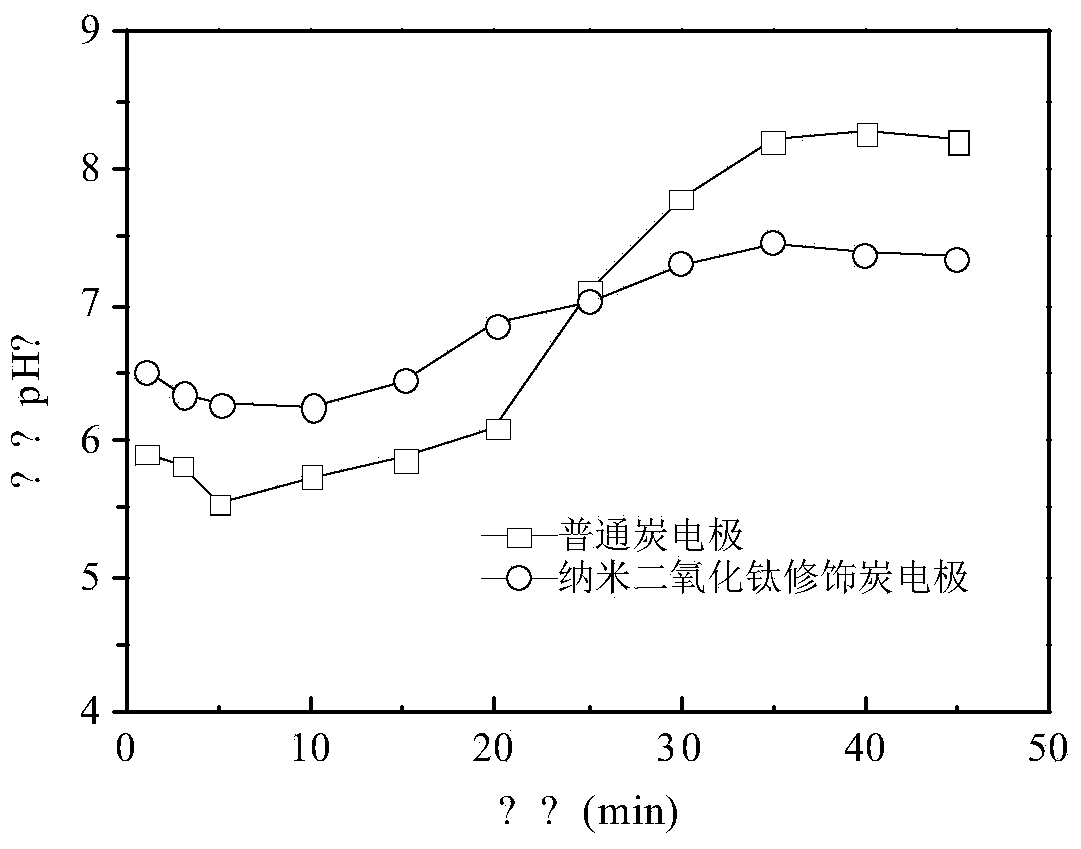

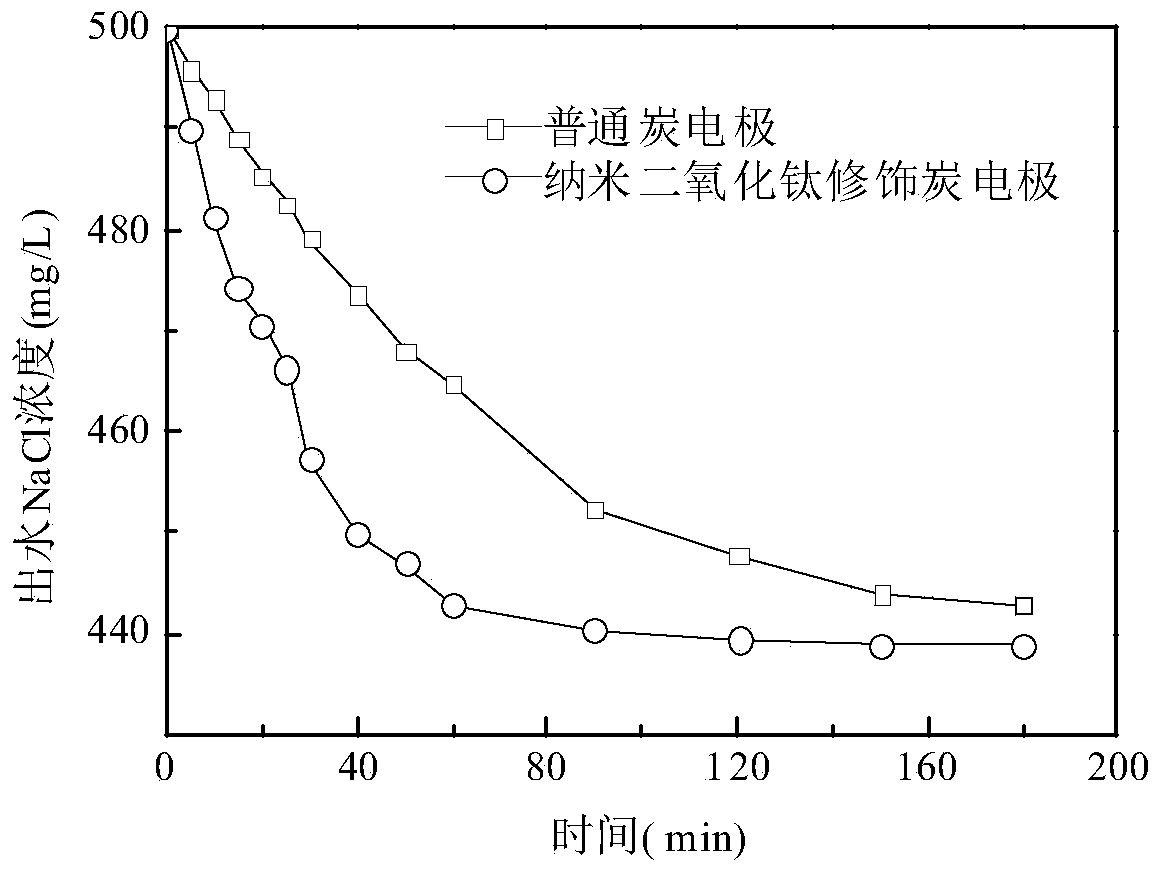

A technology of nano-titanium dioxide and modification method, which is applied in the field of nano-titanium dioxide modification and surface modification of carbon electrode pores by nano-titanium dioxide. To achieve the effect of improving the electric adsorption capacity, reducing the ion exchange effect, and increasing the specific surface utilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Wash the manufactured sheet-shaped electro-adsorption desalting carbon electrode with a thickness of 0.5mm and a size of 70mm×70mm with distilled water to remove the ash inside the electrode, wash it several times until the pH value is 7, and then dry it to a constant temperature. Heavy.

[0026] (2) Mix tetrabutyl titanate and ethanol at a volume ratio of 1:5 and stir vigorously (stirring on a magnetic stirrer at a speed of 500 rpm); mix concentrated nitric acid and water at a volume ratio of 1:5, Prepare nitric acid solution (stabilizer); then slowly drop the nitric acid solution into the mixed solution of tetrabutyl titanate and ethanol according to the volume ratio of concentrated nitric acid, tetrabutyl titanate, and ethanol as 1:5:25, and vigorously Stir, and continue stirring vigorously for 30 minutes after the addition of the nitric acid solution is completed, and the solution obtained at this time is nano-titanium dioxide sol.

[0027] (3) Modification tre...

Embodiment 2

[0033] (1) Wash the manufactured sheet-shaped electro-adsorption desalination carbon electrode with a thickness of 1mm and a size of 70mm×70mm with distilled water to remove the ash inside the electrode, wash it several times until the pH value is close to 7, and then dry it to a constant weight .

[0034] (2) Mix tetrabutyl titanate and glycerol at a volume ratio of 1:5 and stir vigorously (stirring on a magnetic stirrer at a speed of 300 rpm); mix concentrated nitric acid and water at a volume ratio of 1: 10. Prepare nitric acid solution (stabilizer); then slowly drop the nitric acid solution into the mixture of tetrabutyl titanate and glycerol according to the volume ratio of concentrated nitric acid, tetrabutyl titanate, and glycerol as 1:5:25. Mixed solution, and vigorously stirred, continued to stir vigorously for 30 minutes after the nitric acid solution was added dropwise, and the solution obtained at this time was nano-titanium dioxide sol.

[0035] (3) Modification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com