Novel synthetic method for lanthanum-manganese doped strontium ferrite magnetic powder

A magnetic powder, strontium ferrite technology, applied in the field of co-precipitation method, can solve the problems of impurity separation, product uniformity is not as good as co-precipitation, etc., and achieve the effect of improving product purity, expanding application and improving magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

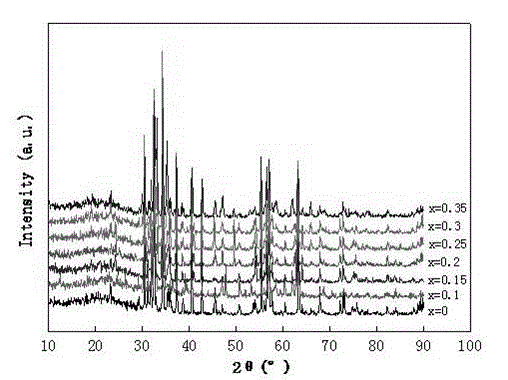

[0023] FeCl 3 , La (NO 3 )·6H 2 O, SrCl 2 4H 2 O, MnCl 2 4H 2 O was dissolved in deionized water, stirred on a stirrer, then poured into the triethylamine solution, stirred while pouring, until no precipitation was precipitated, then stirred on a heating type stirrer at 70°C for 1 h, and suction filtered with a Buchner funnel. The precipitate was dried in a drying oven at 120°C, ground into powder, baked in a muffle furnace at 900°C and kept for 2 hours. figure 1 The XRD patterns of pre-fired powders with different doping amounts of rare earths after annealing at 900°C show that the crystal lattice of the sample does not change after annealing at 900°C, and a single strontium ferrite phase is formed, which shows that La 3+ , Mn 2+ The ions have been fully incorporated into the strontium ferrite lattice structure in the form of interstitials. According to the XRD pattern, the grain size of the sample calculated by Scherrer's formula is about 280nm, which is much smaller...

Embodiment 2

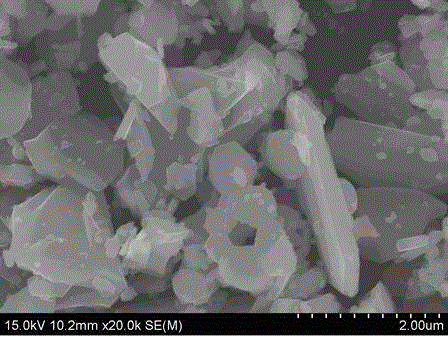

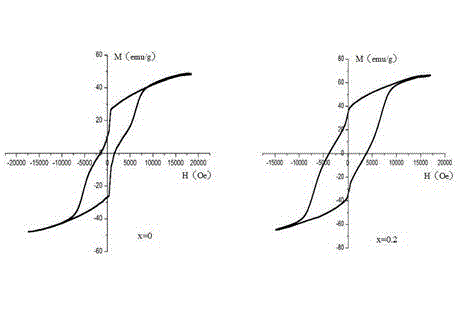

[0025] FeNO 3 , La (NO 3 ) 3 ·6H 2 O, SrCl 2 4H 2 O, MnCl 2 4H 2 O dissolved in triethylamine, replacing La-Mn with M-type strontium ferrite Sr 1-x Fe 12-x La x mn x o 19 (x=0~0.35) As a precursor, stir on a stirrer, then pour into triethylamine solution, stir while pouring, until no precipitation occurs, then stir for 1h on a heating stirrer at 70°C, use Brookfield The funnel was suction-filtered, and the precipitate was dried in a drying oven at 120°C, ground into powder, put into a muffle furnace for roasting at 900°C and kept for 2 hours. figure 2 It is a scanning electron micrograph of controllable composition x=0.2. SEM shows that the product has a diameter of about 200nm, a nanorod with an aspect ratio of 10:1 and a hexagonal flake powder with a diameter of 500nm. Depend on Figure 6 It can be seen that the sample only contains Sr, La, Mn, Fe, O elements, which also shows that the prepared sample does not contain any impurities. From the composition of do...

Embodiment 3

[0027] FeCl 3 、LaCl 3 ·6H 2 O, SrCl 2 4H 2 O, MnCl 2 4H 2 O was dissolved in deionized water and La-Mn was substituted for M-type strontium ferrite Sr 1-x Fe 12-x La x mn x o 19 (x=0~0.35) As a precursor, stir on a stirrer, then pour into triethylamine solution, stir while pouring, until no precipitation occurs, then stir on a heating stirrer at 50°C for 1h, use Brookfield The funnel was suction-filtered, and the precipitate was dried in a drying oven at 120°C, ground into powder, put into a muffle furnace for roasting at 900°C and kept for 2 hours. Figure 4 is the change of the specific saturation magnetization and specific residual magnetization of the sample with the doping amount x. When the doping amount x=0.15, the coercive force is higher, and other doping amounts, the coercive force drops faster, which shows that the La-Mn doping amount can effectively control the coercive force of strontium ferrite, see Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com