High-flocculation capability bacterial strain and use thereof

A flocculation and capacity technology, applied to strains with high flocculation ability and their application fields, can solve problems such as unsatisfactory treatment effect and environmental pollution, and achieve the effect of improving sewage treatment effect, improving treatment efficiency and reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

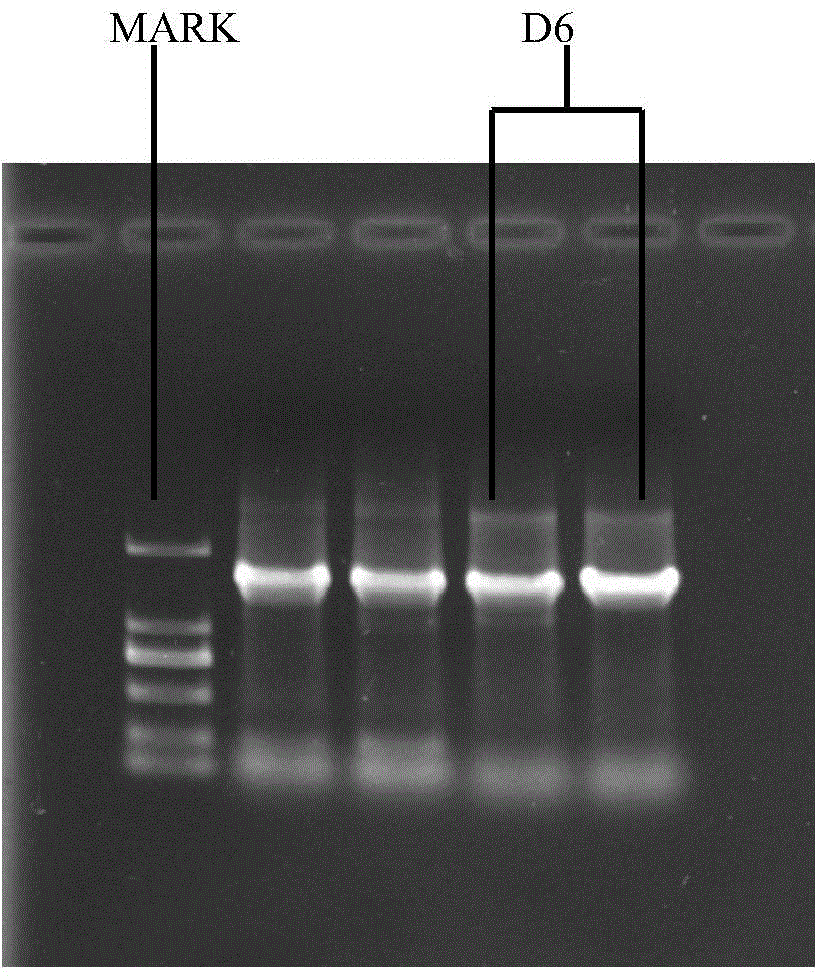

[0021] Example 1 Acquisition and Identification of Bacillus muralis D6

[0022] (1) Screening method of D6

[0023] Bacterial strains were isolated from the bottom sludge of a meat and poultry processing factory in Shenyang and the activated sludge of the aeration tank by dilution coating and plate streaking method, and 55 strains were isolated and purified. After preliminary screening, 15 strains were fermented The product can cause flocculation of kaolin suspension, and flocs are produced, which proves that the fermentation product has flocculation characteristics. The 15 strains obtained after the primary screening were re-screened, and the flocculation ability of the microbial flocculant was characterized by the flocculation rate. The flocculation rate is the largest, which is 96.77%.

[0024] Table 1 Re-screening results

[0025]

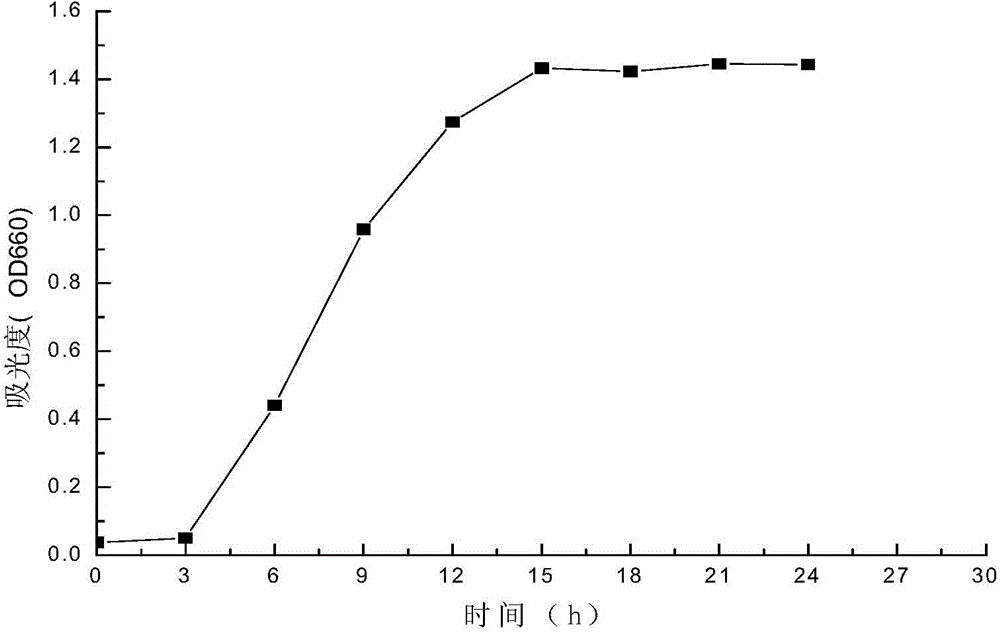

[0026] (2) Determination of the growth curve of strain D6

[0027] Liquid medium formula: 1000mL distilled water, 3g beef extract, 10g ...

Embodiment 2

[0048] Example 2 Determination and application of optimal flocculation conditions for degradation of slaughter wastewater

[0049] (1) Preparation of microbial flocculant: Insert strain D6 into 50mL fermentation medium (1000mL distilled water, 20g soluble starch, KH 2 PO 4 2g,K 2 HPO 4 5g, (NH 4 ) 2 SO 4 0.2g, NaCl 0.1g, urea 0.5g, yeast extract 0.5g, MgSO 4 ·7H 2 O 0.2g, initial pH 7.0, sterilized at 121°C for 20min) in a 250mL Erlenmeyer flask, cultured in a constant temperature shaking incubator with an oscillator temperature of 30°C and a rotation speed of 160r / min for 72h. After cultivation, the fermented liquid was centrifuged at 4000r / min for 30min with a centrifuge, and the supernatant was taken as the microbial flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com