Method for completely removing diamond-like carbon film from surface of workpiece

A workpiece surface, diamond technology, applied in the field of completely removing the coating on the workpiece surface, can solve the problems of destructive ablation of the workpiece substrate, incomplete deplating of the diamond-like carbon film, and difficulty in obtaining the diamond carbon film, etc., to achieve strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

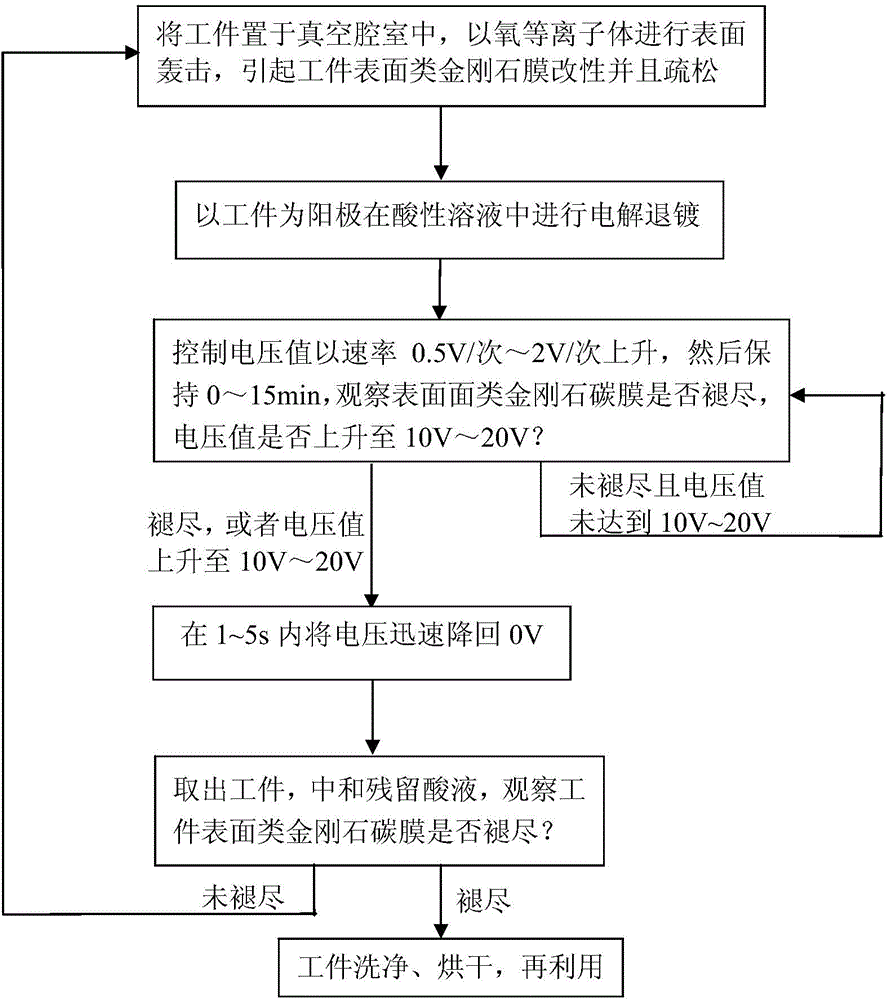

Method used

Image

Examples

Embodiment 1

[0045] In this embodiment, the workpiece substrate is made of iron and steel, and the surface of the workpiece substrate is a diamond-like carbon film. Deplating the diamond-like carbon film comprises the following steps:

[0046] (1) Place the workpiece in a vacuum chamber, use a linear ion beam source to provide an oxygen plasma beam, and accelerate the ion beam to bombard the workpiece under a certain bias, causing the diamond-like film on the surface of the workpiece to be modified and loose in structure. The time is 180min;

[0047] (2) Use the workpiece as an anode at room temperature, and perform electrolysis in a sulfuric acid electrolyte with a volume concentration of 1%. From 0V, the voltage is controlled to increase slowly and gradually at a step rate of 2V each time, and stay for 2min after each voltage increase. Observe whether the carbon film on the surface of the workpiece fades away. When the voltage rises to 8V and observe for 1 minute, the diamond-like carbo...

Embodiment 2

[0050] This example is a comparative example of Example 1.

[0051] In this embodiment, the workpiece is exactly the same as in Embodiment 1. Deplating the diamond-like carbon film on the surface of the workpiece substrate comprises the following steps:

[0052] (1) Same as step (1) of Example 1;

[0053] (2) Use the workpiece as an anode at room temperature, and perform electrolysis in a sulfuric acid electrolyte with a volume concentration of 1%. From 0V, the voltage is controlled to increase slowly and gradually at a step rate of 2V each time, and stay for 2min after each voltage increase. Observe whether the carbon film on the surface of the workpiece has faded. When the voltage is increased to 8V and observed for 1 minute, the diamond-like carbon film on the surface of the workpiece has faded. Slowly lower the voltage to 0V. It takes 1 minute. During the step-down process, the surface of the workpiece is ablated and emits Pungent smell.

Embodiment 3

[0055] This example is another comparative example of Example 1. Include the following steps:

[0056] In this embodiment, the workpiece is exactly the same as in Embodiment 1. Deplating the diamond-like carbon film on the surface of the workpiece substrate comprises the following steps:

[0057] (1) Same as step (1) of Example 1;

[0058] (2) Use the workpiece as an anode at room temperature, and perform electrolysis in a sulfuric acid electrolyte with a volume concentration of 1%. From 0V, the voltage is controlled to increase slowly and gradually at a step rate of 2V each time, and stay for 2min after each voltage increase. Observe whether the carbon film on the surface of the workpiece fades away. When the voltage rises to 22V, the surface of the workpiece is ablated and emits a pungent smell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com