High energy laser beam stray light energy measuring system

A high-energy laser beam and energy measurement technology, applied in the field of ring-shaped high-energy laser beam stray light energy measurement and high-energy laser beam stray light energy measurement system, can solve problems such as abnormal output, long transmission distance of high-energy laser, damage to inner channels, etc. Achieve the effect of improving response speed and temperature measurement accuracy, good scalability and portability, and improving energy measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

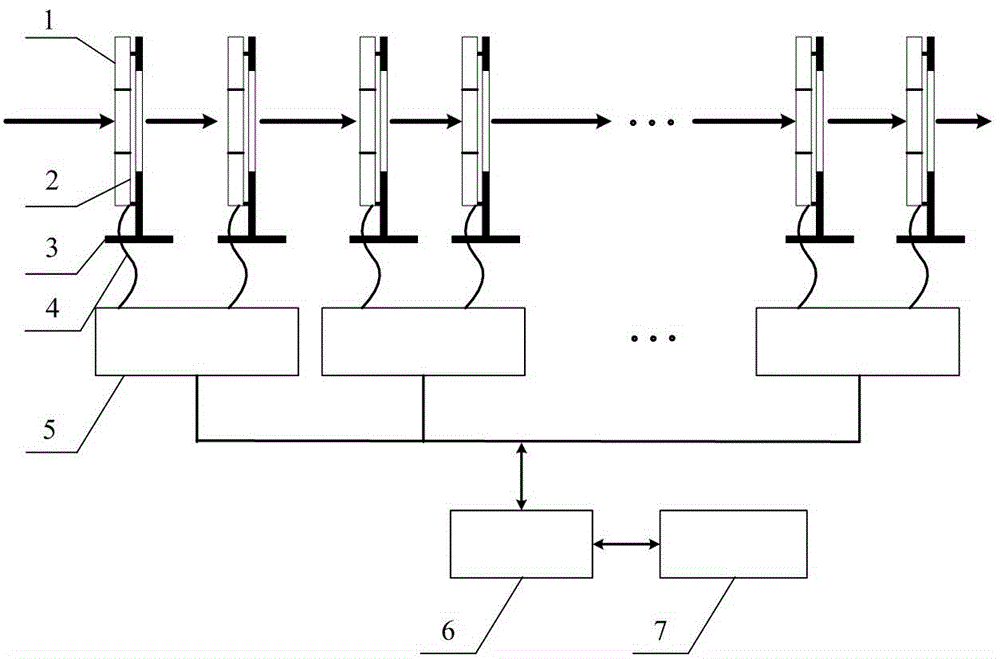

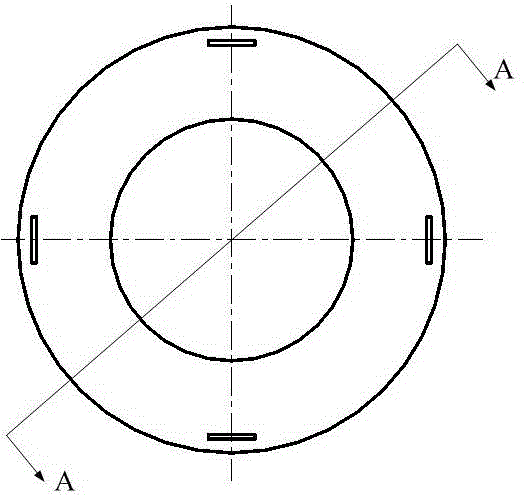

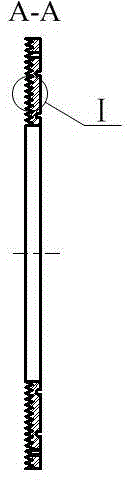

[0022] figure 1 It is a schematic structural diagram of a high-energy laser beam stray light energy measurement system of the present invention, and Fig. 2 (a) is a schematic structural diagram of an absorption aperture in the present invention, (b) is a schematic cross-sectional view of the absorption aperture AA, and (c) is an absorption light Partial enlarged view of appendix I, image 3 It is a schematic diagram of the installation layout of the thermocouple temperature sensor in the present invention, Figure 4 It is a schematic diagram of series connection of thermocouple temperature sensors in the present invention. exist Figure 1 ~ Figure 4 Among them, the high-energy laser beam stray light energy measurement system of the present invention includes several absorption apertures, thermocouple temperature sensors 2, aperture fixing brackets 3, lead wires 4, temperature acquisition modules 5, network switches 6, and host computers 7; The absorption diaphragm 1 is circ...

Embodiment 2

[0031] The structure of embodiment 2 is basically the same as that of embodiment 1. The difference is that the inner diameter of the absorption diaphragm in this embodiment is 1.1 times the outer diameter of the measured laser beam, and the ring-shaped V-shaped groove clip set on the light-facing surface of the absorption diaphragm The angle α is 45°. Sixty-four thermocouple temperature sensors with the same structure are bonded to each absorption aperture. The thermocouple temperature sensors are divided into four groups, and the sixteen thermocouple temperature sensors in each group are correspondingly bonded to the The thermocouple temperature sensor fixing slot located on a concentric circle on the backlight surface of the absorption diaphragm is made of red copper as the material of the absorption diaphragm.

Embodiment 3

[0033] Embodiment 3 has basically the same structure as Embodiment 1. The difference is that in this embodiment, the included angle α of the ring-shaped V-shaped groove arranged on the light-facing surface of the absorption diaphragm is 60°, and each absorption diaphragm is bonded with four Ten thermocouple temperature sensors with the same structure, the thermocouple temperature sensors are divided into five groups, and the eight thermocouple temperature sensors in each group correspond to the thermocouple temperature sensors bonded on a concentric circle on the backlight surface of the absorption aperture. slot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com