Preparation method for high-nutrition and high-function oatmeal

An oatmeal, high-function technology, used in food preparation, food heat treatment, food drying and other directions, can solve problems such as decline, unfavorable industrial production, and easy breeding of microorganisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

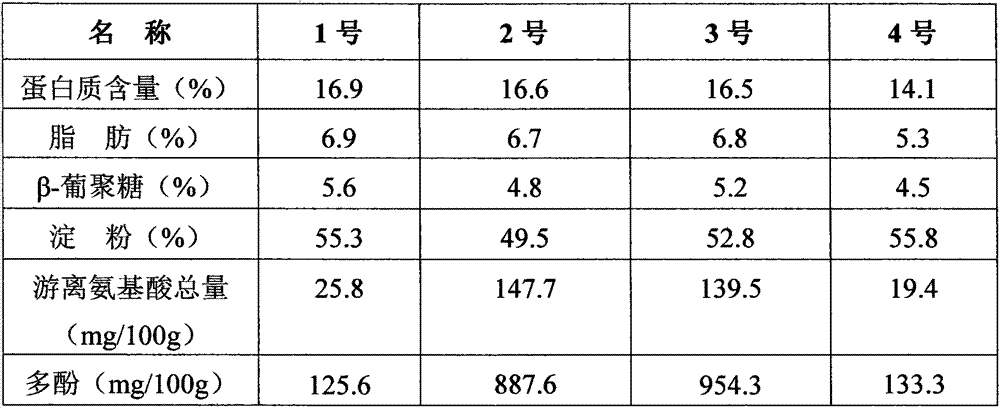

Embodiment example 1

[0020] 1. Raw material screening: select the fresh shelled oat grains of the year, and measure the main nutritional components. The raw material β-glucan, protein and fat contents are 5.63%, 16.88% and 6.87% respectively (the results are all calculated on a dry basis);

[0021] 2. Pretreatment: Remove weeds, stones and other impurities through the primary selection machine and selection machine, and sieve to remove broken and unfulfilled oat grains, weigh 10kg of screening raw materials; add 25kg of tap water to rinse and drain surface moisture;

[0022] 3. Disinfection: Soak the cleaned oat grains in 25kg, 1% sodium hypochlorite aqueous solution at room temperature (25±2°C) for 6 minutes, and drain the surface water;

[0023] 4. Soaking: Place the sterilized oat grains in the germination bed, add 30kg of clean water, cover them to avoid light, and pass in filtered clean air with an air flow rate of 0.06 liters per minute. Soak them in water at 37±2°C for 7 hours. Change the ...

Embodiment example 2

[0040] 1. Screening of raw materials: The fresh shelled oat grains of the year were selected, and the main nutritional components were determined. The contents of β-glucan, protein and fat in the raw materials were 5.74%, 16.32% and 6.60% respectively (the results were all calculated on a dry basis).

[0041] 2. Pretreatment: Remove impurities such as weeds and stones through the primary selection machine and selection machine, sieve the broken and unfulfilled oat grains, weigh 20kg of the screened raw materials; add 45kg of tap water to rinse, and drain the surface moisture;

[0042] 3. Disinfection: Soak the cleaned oat grains in 40kg, 1% sodium hypochlorite aqueous solution at room temperature (25±2°C) for 8 minutes, and drain the surface water;

[0043] 4. Soaking: Place the sterilized oat grains in the germination bed, add 50kg of clean water, cover them to avoid light, and pass in filtered clean air with an air volume of 0.08 liters per minute. Soak them in water at 38±2...

Embodiment example 3

[0051] 1. Screening of raw materials: Select the fresh shelled oat grains of the year, and measure the main nutritional components. The raw materials β-glucan, protein and fat contents are 5.55%, 16.97% and 6.77% respectively (the results are all calculated on a dry basis).

[0052] 2. Pretreatment: Remove impurities such as weeds and stones through the primary selection machine and selection machine, sieve the broken and unfulfilled oat grains, weigh 30kg of the screened raw materials; add 65kg of tap water to rinse, and drain the surface moisture;

[0053] 3. Disinfection: soak the cleaned oat grains in 70kg, 1% sodium hypochlorite aqueous solution at room temperature (25±2°C) for 10 minutes, and drain the surface water;

[0054] 4. Soaking: Place the sterilized oat grains in the germination bed, add 75kg of clean water, cover to avoid light, pass in filtered clean air with an air flow rate of 0.06 liters per minute, soak in water at 37±2°C for 6.5 hours , Change the water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com