Preparation method of garlic oil

A technology of garlic oil and garlic, which is applied in the fields of fat oil/fat refining, fat oil/fat production, and fat production. Effect of cleaning and improving extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

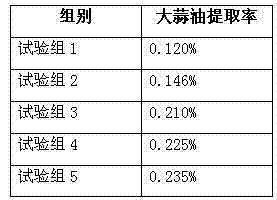

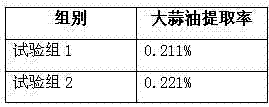

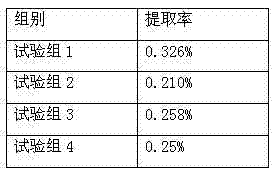

Examples

Embodiment 1

[0025] Example 1: A preparation method of garlic oil, comprising the steps of:

[0026] Step a: Washing and beating: Select high-quality garlic without moths and mildew, separate the garlic and peel it, wash it with clean water, drain the water, and grind it into garlic pulp at 30°C;

[0027] Step b: enzymatic hydrolysis: add cellulase to the garlic pulp in step a, adjust the pH value of the garlic pulp to 6.5 with a phosphate buffer solution, and enzymolyze the garlic pulp at 30°C for 60 minutes to obtain the first primary enzymatic solution;

[0028] Step c: Filter the enzymolysis solution for the first time: filter the first enzymolysis solution in step b to obtain the filter residue and the first filtrate, add cellulase to the filter residue, and use the buffer solution to adjust the pH value of the filter residue to 6.5 , enzymatically hydrolyzing the filter residue for 60 minutes at a temperature of 30°C to obtain a second enzymatic hydrolysis solution;

[0029] Step ...

Embodiment 2

[0034] Example 2: A method for preparing garlic oil, comprising the following steps: step a: cleaning and beating: selecting high-quality garlic without moths and mildew, separating the garlic into petals and peeling the garlic, washing it with clean water, draining the water, and drying the garlic at 10°C. garlic pulp under the conditions; step b: enzymatic hydrolysis: add cellulase to the garlic pulp in step a, and use phosphate buffer solution to adjust the pH value of the garlic pulp to 5.0, so that the garlic pulp can be heated at a temperature of 25°C Under the condition of enzymatic hydrolysis for 40 minutes, the first enzymatic hydrolysis solution was obtained; step c: the first filtration of the enzymatic hydrolysis solution: filter the first enzymatic hydrolysis solution in step b to obtain the filter residue and the first filtrate, and add to the filter residue Cellulase, using a buffer solution to adjust the pH of the filter residue to 5.0, and enzymatically hydro...

Embodiment 3

[0035] Example 3: A preparation method of garlic oil, comprising the steps of:

[0036] Step a: Washing and beating: select high-quality garlic without moths and mildew, separate the garlic and peel it, wash it with clean water, drain the water, and grind it into garlic pulp at 20°C;

[0037] Step b: enzymatic hydrolysis: add cellulase to the garlic pulp in step a, adjust the pH value of the garlic pulp to 5.5 with a phosphate buffer solution, and enzymolyze the garlic pulp at 30°C for 140 minutes to obtain the first primary enzymatic solution;

[0038] Step c: Filter the enzymolysis solution for the first time: filter the first enzymolysis solution in step b to obtain the filter residue and the first filtrate, add cellulase to the filter residue, and use the buffer solution to adjust the pH of the filter residue to 5.5 , enzymatically hydrolyzing the filter residue for 90 minutes at a temperature of 30°C to obtain a second enzymolysis solution;

[0039] Step d: the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com