Wool fabric anti-pilling finishing method

An anti-pilling and fabric technology, which is applied in the field of anti-pilling of wool fabrics, can solve the problems of poor bonding fastness between finishing agents and fibers, and achieve the effects of avoiding easy yellowing, improving bonding fastness and short finishing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

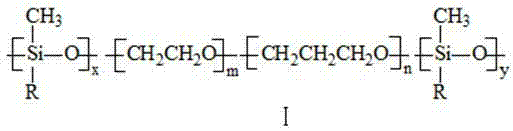

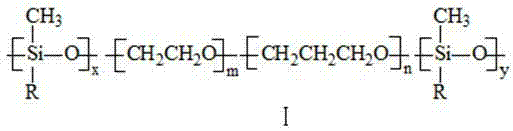

Image

Examples

Embodiment 1

[0038] Example 1: Anti-pilling finishing of wool fabric

[0039] In the wool batch dyeing machine, (1) impregnate 100Kg of wool fabric with enzyme and reduction treatment solution with a bath ratio of 1:10; add 0.2Kg of alkaline protease and 0.2Kg of 1-dodecylazacyclohepta to the aqueous solution Alkane-2-one, adjust the pH of the solution to 8.0 with an appropriate amount of borax to obtain an enzyme treatment solution. The immersion treatment temperature is 55°C and the immersion treatment time is 15 minutes; then 1.5 Kg of sodium tetrahydroborate is added to the above enzyme treatment solution, Sodium bisulfite 5.0 Kg, sodium gluconate 3.5 Kg, immersion treatment at 55°C for 15 minutes is reduction treatment. After the treatment is completed, drain and wash with water at 40°C for 10 minutes;

[0040] (2) Immerse the washed wool fabric in the oxidation and softening treatment solution with a bath ratio of 1:10; add 0.25Kg of hydrogen peroxide and 0.15Kg of tetraacetylethylenediam...

Embodiment 2

[0043] Example 2: Anti-pilling finishing of wool fabric

[0044] In the wool batch dyeing machine, (1) impregnate 100Kg of wool fabric with enzyme and reduction treatment solution with a bath ratio of 1:10; add 0.5Kg of alkaline protease and 1.0Kg of 1-dodecylazacyclohepta to the aqueous solution Alkane-2-one, adjust the pH of the solution to 8.0 with an appropriate amount of borax to obtain an enzyme treatment solution. The immersion treatment temperature is 50°C and the immersion treatment time is 20 minutes; then add 2.0 Kg of sodium tetrahydroborate to the above enzyme treatment solution, Sodium bisulfite 6.5Kg, sodium gluconate 4.0Kg, immersion treatment at 50℃ for 10min is reduction treatment. After the treatment is completed, drain the liquid and wash with water at 40℃ for 10 min;

[0045] (2) Immerse the washed wool fabric in the oxidation and softening treatment solution with a bath ratio of 1:10; add 0.5Kg hydrogen peroxide and 0.2Kg tetraacetylethylenediamine to the aque...

Embodiment 3

[0048] Example 3: Anti-pilling finishing of wool fabric

[0049] In the wool batch dyeing machine, (1) impregnate 100Kg wool fabric with enzyme and reduction treatment solution with a bath ratio of 1:15; add 1.0Kg alkaline protease and 1.5Kg 1-dodecylazacyclohepta to the aqueous solution Alkane-2-one, adjust the pH of the solution to 7.5 with an appropriate amount of borax to obtain an enzyme treatment solution. The immersion treatment temperature is 45°C and the immersion treatment time is 30 minutes; then 2.5 Kg of sodium tetrahydroborate is added to the above enzyme treatment solution, Sodium bisulfite 7.8 Kg, sodium gluconate 5.0 Kg, immersion treatment at 45°C for 10 minutes is reduction treatment. After the treatment is completed, drain and wash with water at 40°C for 10 minutes;

[0050] (2) Immerse the washed wool fabric in the oxidation and softening treatment solution, the bath ratio is 1:10; add 0.1Kg hydrogen peroxide and 0.05Kg tetraacetyl ethylene diamine to the aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com