Fruit and vegetable nutritional ice cream and preparation method thereof

An ice cream, fruit and vegetable technology, applied in the field of fruit and vegetable nutritional ice cream and its preparation, can solve the problems that the fruit and vegetable ice cream cannot present the fruit and vegetable flavor as a whole, the nutrient content of the peel is wasted, and the ice cream has a weak aroma, so as to achieve rich varieties, increased nutrition, and fine taste slippery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

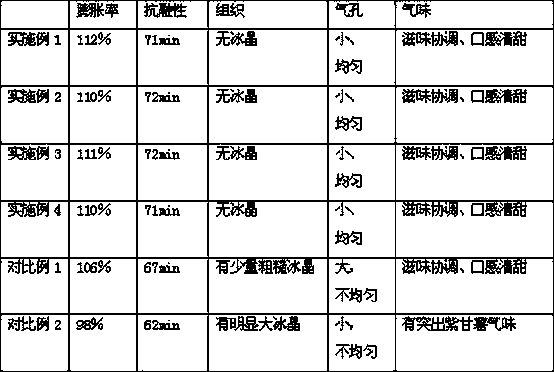

Examples

Embodiment 1

[0027] Taking purple sweet potato as an example, choose purple sweet potato with no pests, no scars, uniform size and plump shape, remove fibrous roots, wash it in tap water, cut it into potato chips of about 3 mm, and blanch it in boiling water for 3 minutes. Drain in a stainless steel tray and let cool to room temperature. Put the drained potato chips in an oven, blow dry them at 50°C for 12 hours, until the purple potato chips have a moisture content of 5%, and then crush them into 120-mesh coarse powder; put the purple potato coarse powder at 12°C Make 400-mesh purple sweet potato superfine powder, and adopt microwave sterilization to obtain purple sweet potato superfine powder.

[0028] The specific process for preparing purple sweet potato ice cream is as follows:

[0029] a. Preparation of emulsifier water-sugar solution: mix 0.1 part of emulsifier and 30 parts of sugar evenly, add 45°C water, mix and dissolve for later use;

[0030] b. Preparation of ice cream base l...

Embodiment 2

[0038] Taking apples as an example, choose apples that are free from pests and rot, wash them in tap water, cut them into apple slices of about 3 mm, place them in an oven, and dry them with air at 45°C for 6 hours until the moisture content reaches 5 The apple slices of one portion were crushed into 100-mesh coarse powder; the apple coarse powder was made into 600-mesh apple superfine powder under the condition of 8°C, and microwave sterilization was adopted to obtain apple superfine powder. Apples are rich in vitamin C, which is good for those who lack vitamin C.

[0039] The concrete process of apple ice cream preparation is:

[0040] a. Preparation of emulsifier water-sugar solution: mix 0.3 parts of emulsifier and 35 parts of sugar evenly, add 60°C water, mix and dissolve for later use;

[0041] b. Preparation of ice cream base liquid: put 30 parts of fresh milk and 20 parts of cream in the batching tank, then slowly pour the emulsifier water sugar solution into the tank...

Embodiment 3

[0049] Taking pumpkins as an example, select pumpkins that are free from pests and rot, wash them in tap water, cut them into slices of about 3 mm, place them in an oven, and dry them with blast air at 35 °C for 24 h until the water content reaches 5 mm. The pumpkin slices of one portion were crushed into 80-mesh coarse powder; the pumpkin coarse powder was made into 500-mesh pumpkin superfine powder under the condition of 10° C., and microwave sterilization was adopted to obtain pumpkin superfine powder. Pumpkin is rich in nutrients such as vitamin A, trace elements cobalt and pectin. It can be eaten by the general population, especially for obese and elderly people with constipation.

[0050] The specific process of pumpkin ice cream preparation is:

[0051] a. Preparation of emulsifier water sugar solution: mix 0.2 parts of emulsifier and 25 parts of sugar evenly, add 50°C water, mix and dissolve for later use;

[0052] b. Preparation of ice cream base liquid: put 50 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com