Functionalized mesoporous bioglass porous scaffolds as well as preparation method and application thereof

A bioglass, porous scaffold technology, applied in medical science, prosthesis, etc., can solve the problems of limited bone repair capacity, damage to mesoporous structure, low porosity, etc., to achieve enhanced hydrophilicity, enhanced adsorption, and improved bone repair. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033](1) Add 4g P123 (a three-block copolymer, full name: polyethylene oxide-polypropylene oxide-polyethylene oxide three-block copolymer, its molecular formula is: PEO-PPO-PEO) , 6.7g ethyl orthosilicate, 1.4g Ca(NO 3 ) 2 4H 2 O, 0.73g of triethyl phosphate and 1.0g of 0.5M hydrochloric acid were added to 60.0g of absolute ethanol, stirred at 30°C for 18h to form a transparent sol, and the obtained sol was placed in a petri dish and volatilized at 27°C for 48h to form gel, and then roast the obtained gel in a muffle furnace at 600°C for 5 hours, take it out and grind it to obtain mesoporous bioglass powder;

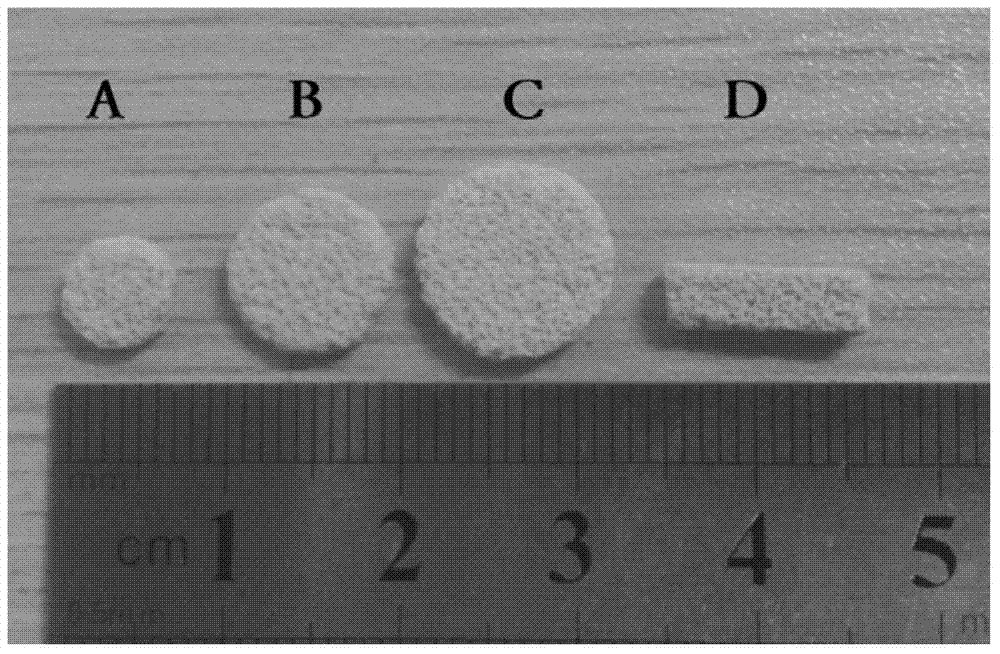

[0034] (2) Mix 0.3g of mesoporous bioglass powder, 0.05g of polyvinylpyrrolidone powder and 0.3g of polyethylene glycol particles evenly, put them into a cylindrical steel mold with a diameter of 0.5cm, and press them under a pressure of 3MPa. The formed mesoporous bioglass was put into a muffle furnace at 500° C. for 6 hours and fired for 6 hours to obtain a cylindr...

Embodiment 2

[0041] (1) Mix 4g P123, 7.5g tetraethyl orthosilicate, 0.5g Ca(NO 3 ) 2 4H 2 O, 0.73g of triethyl phosphate and 1.0g of 0.5M hydrochloric acid were added to 60.0g of absolute ethanol, stirred at 28°C for 24h to form a transparent sol, and the obtained sol was placed in a petri dish and volatilized at 25°C for 36h to form gel, and then roast the obtained gel in a muffle furnace at 500°C for 5 hours, take it out and grind it to obtain mesoporous bioglass powder;

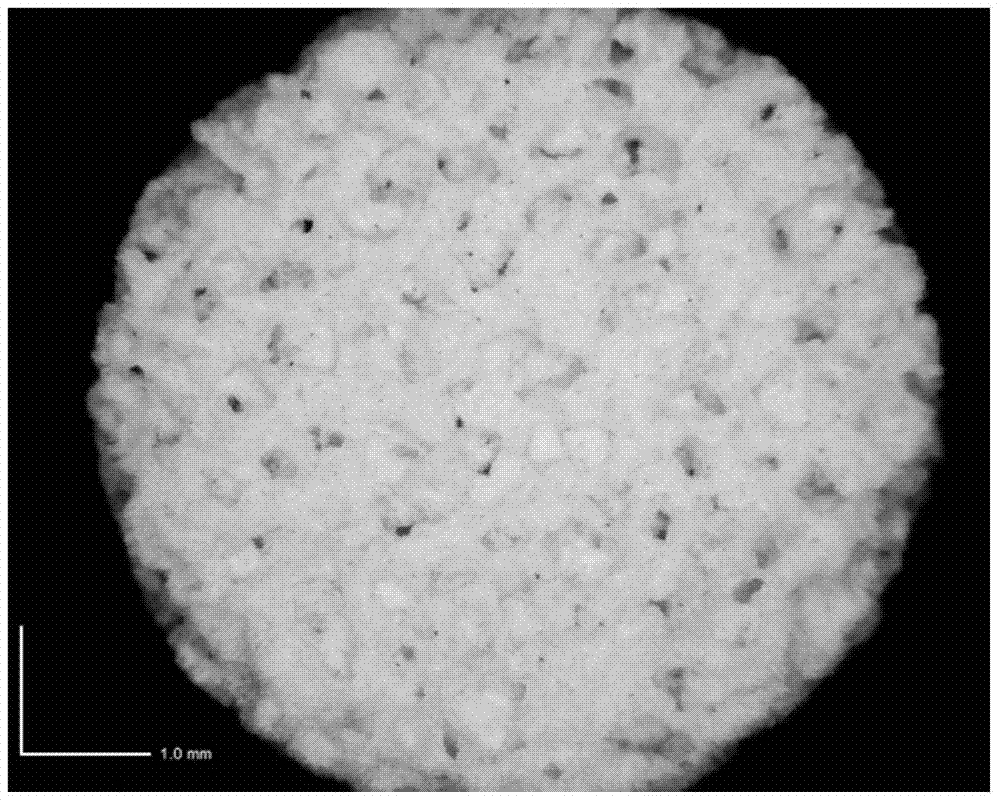

[0042] (2) Mix 0.4g of mesoporous bioglass powder, 0.1g of polyvinylpyrrolidone powder and 0.4g of polyethylene glycol particles evenly, put it into a cylindrical steel mold with a diameter of 1cm, and press it under a pressure of 4MPa. The shaped mesoporous bioglass was placed in a muffle furnace at 600°C for 5 h and fired to obtain a cylindrical mesoporous bioglass scaffold MBG-SCA with a diameter of 1 cm and a thickness of 0.3 cm.

[0043] Such as figure 1 As shown in B in , it can be roughly observed that there...

Embodiment 3

[0045] (1) Mix 8g P123, 5.8g tetraethyl orthosilicate, 2.4g Ca(NO 3 ) 2 4H 2 O, 0.73g of triethyl phosphate and 1.0g of 0.5M hydrochloric acid were added to 60.0g of absolute ethanol, stirred at 32°C for 12h to form a transparent sol, and the obtained sol was placed in a petri dish and volatilized at 30°C for 72h to form gel, and then roast the obtained gel in a muffle furnace at 700°C for 5 hours, take it out and grind it to obtain mesoporous bioglass powder;

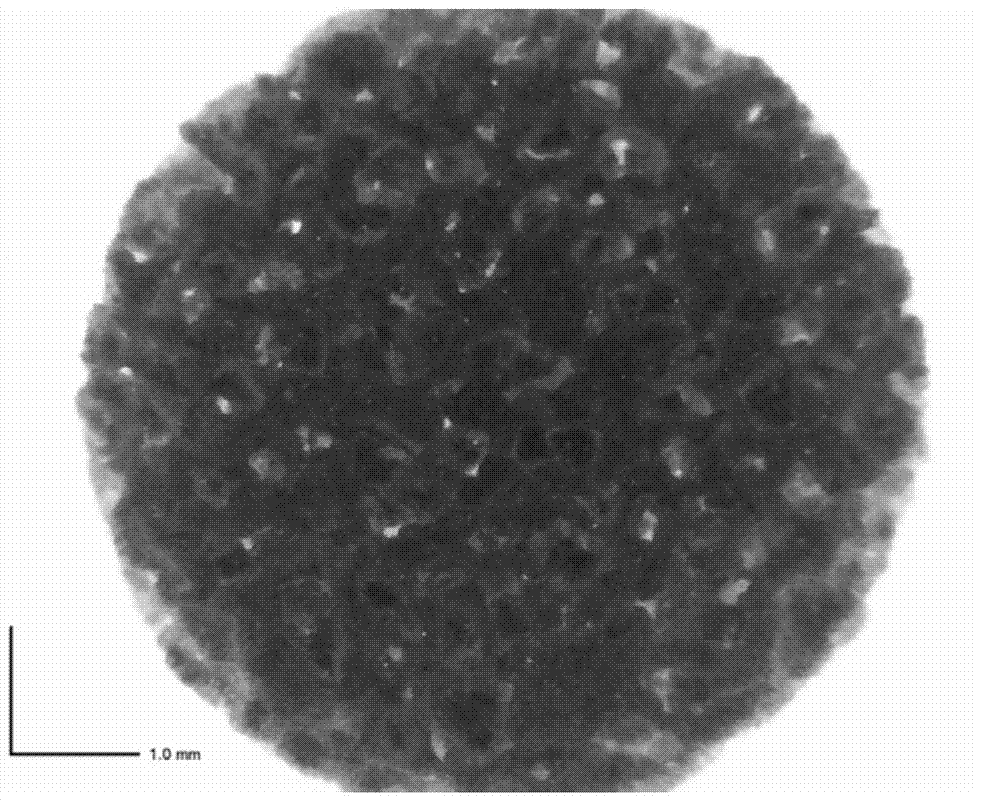

[0046] (2) Mix 0.5g of mesoporous bioglass powder, 0.15g of polyvinylpyrrolidone powder and 0.5g of polyethylene glycol particles evenly, put it into a cylindrical steel mold with a diameter of 1.5cm, and press it under a pressure of 5MPa. The shaped mesoporous bioglass was put into a muffle furnace at 700°C for 4 hours and fired for 4 hours to obtain a cylindrical mesoporous bioglass scaffold MBG-SCA with a diameter of 1.5 cm and a thickness of 0.3 cm.

[0047] Such as figure 1 As shown in C in , it can be roughly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com