A kind of preparation method of the intermediate of apixaban

A technology for intermediates and compounds, applied in the field of preparation of intermediates, can solve problems such as low yield, and achieve the effects of high product yield, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

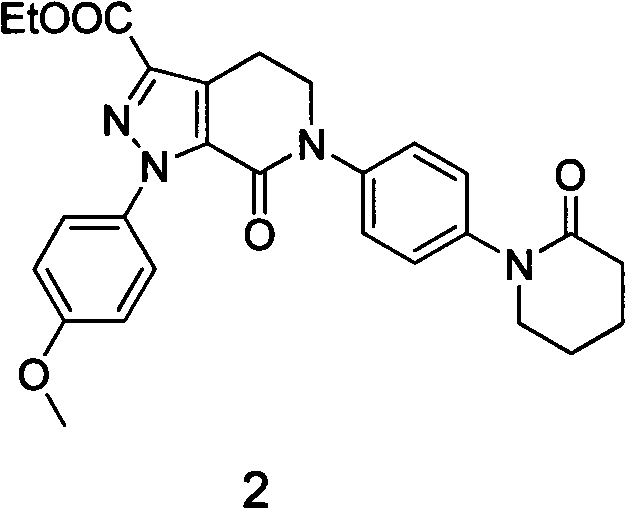

[0030] Example 1: 1-(4-methoxyphenyl)-7-carbonyl-6-[4-(2-carbonylpiperidinyl)phenyl]-4,5,6,7-tetrahydro-1H- Preparation of ethyl pyrazolo[3,4-c]pyridine-3-carboxylate

[0031] Dissolve compound 3 (11.4g, 0.03mol), compound 4 (12.6g, 0.045mol), triethylamine (13.2ml, 0.09mol) in dichloromethane (250ml), reflux for 9 hours, add 4mol / L hydrochloric acid (64ml, 0.25mol), stirred for 2 hours. Liquid separation, extraction with dichloromethane, washing with water, drying over anhydrous magnesium sulfate, evaporation of the solvent to give a reddish-brown solid, which was recrystallized from absolute ethanol to give 12.6 g of a white solid. Yield: 80%, HPLC: 99.7%. (instrument: Agilent1260 high performance liquid chromatography, chromatographic column: C18, column length: 25cm, mobile phase: (water: acetonitrile=50:50), flow rate: 1.0ml / min, wavelength: 254nm, column temperature: 30 ℃, Injection volume: 20 μL).

[0032] MS (ESI, m / z): 489.21[M+1], 506.24[M+NH 4 + ]

[0033] 1...

Embodiment 2

[0034] Example 2: 1-(4-methoxyphenyl)-7-carbonyl-6-[4-(2-carbonylpiperidinyl)phenyl]-4,5,6,7-tetrahydro-1H- Preparation of ethyl pyrazolo[3,4-c]pyridine-3-carboxylate

[0035] Dissolve compound 3 (3.8g, 0.01mol), compound 4 (4.2g, 0.015mol), triethylamine (4.4ml, 0.03mol) in dichloromethane (90ml), reflux for 12 hours, add 4mol / L hydrochloric acid (21ml, 0.08mol), stirred for 2 hours. Liquid separation, extraction with dichloromethane, washing with water, drying over anhydrous magnesium sulfate, evaporation of the solvent to give a reddish-brown solid, which was recrystallized from absolute ethanol to give 4.3 g of a white solid. Yield: 82%, HPLC: 99.6%.

Embodiment 3

[0036] Example 3: 1-(4-methoxyphenyl)-7-carbonyl-6-[4-(2-carbonylpiperidinyl)phenyl]-4,5,6,7-tetrahydro-1H- Preparation of ethyl pyrazolo[3,4-c]pyridine-3-carboxylate

[0037] Dissolve compound 3 (3.0g, 0.008mol), compound 4 (2.5g, 0.0088mol), triethylamine (3.4ml, 0.024mol) in dichloromethane (70ml), reflux for 12 hours, add 4mol / L hydrochloric acid (16ml, 0.06mol), stirred for 2 hours. Separation, extraction with dichloromethane, washing with water, drying over anhydrous magnesium sulfate, evaporation of the solvent to give a reddish-brown solid, which was recrystallized from acetonitrile to give 3.3 g of a white solid. Yield: 80%, HPLC: 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com