Method of preparing a groove grid-control power device

A technology for power devices and trench gates, which is used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., and can solve problems such as poor terminal structure, complicated steps, and poor breakdown voltage and reliability of semiconductor devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

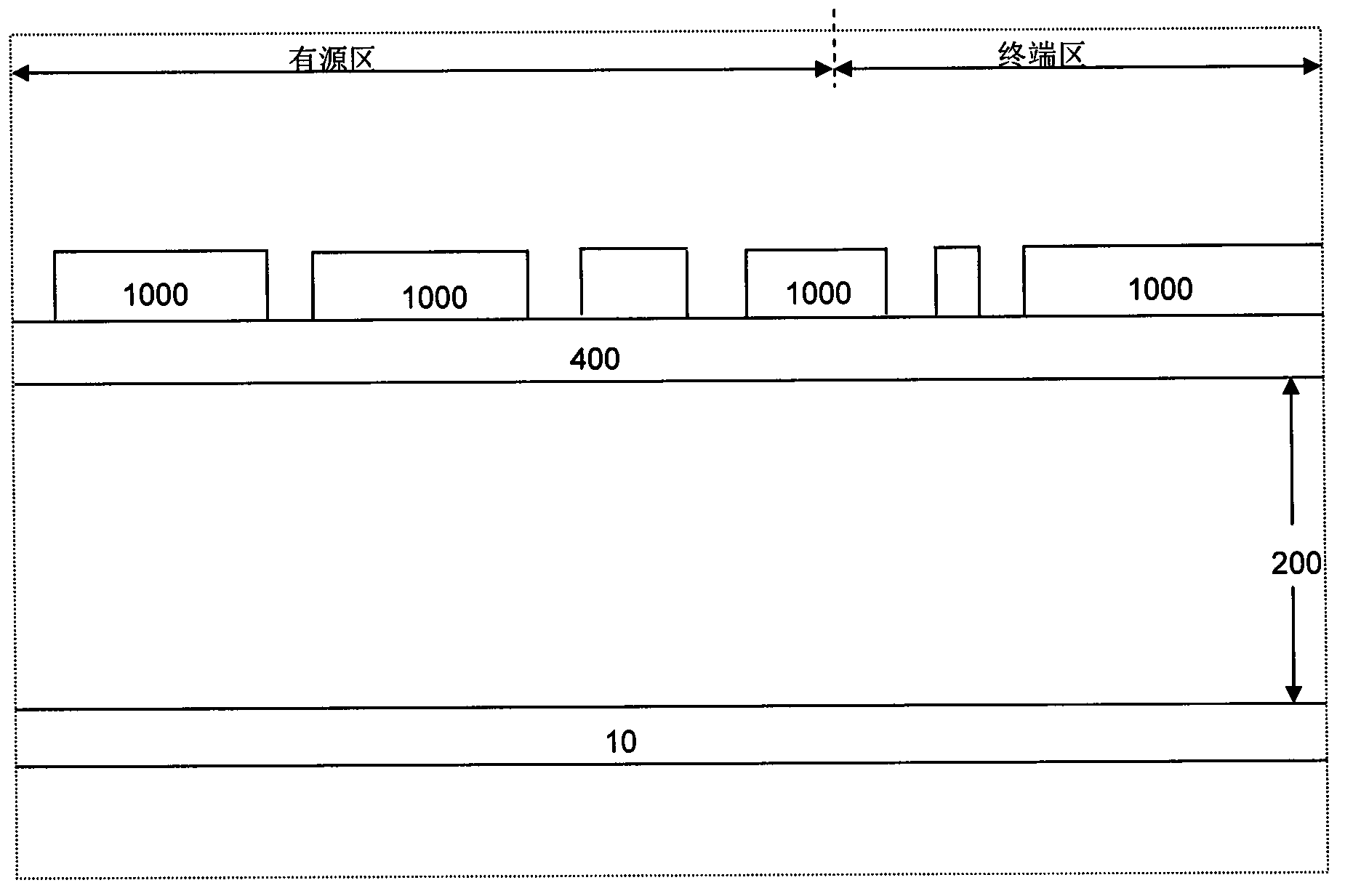

[0086] Such as figure 1 As shown, the epitaxial layer 200 is placed above the substrate 10. First, an oxide layer 400 (with a thickness of 0.3um to 1.5um oxide hard mask) is formed on the epitaxial layer by deposition or thermal growth, and then on the oxide layer A photoresist coating 1000 is deposited and then patterned through a trench mask to expose portions of the oxide layer.

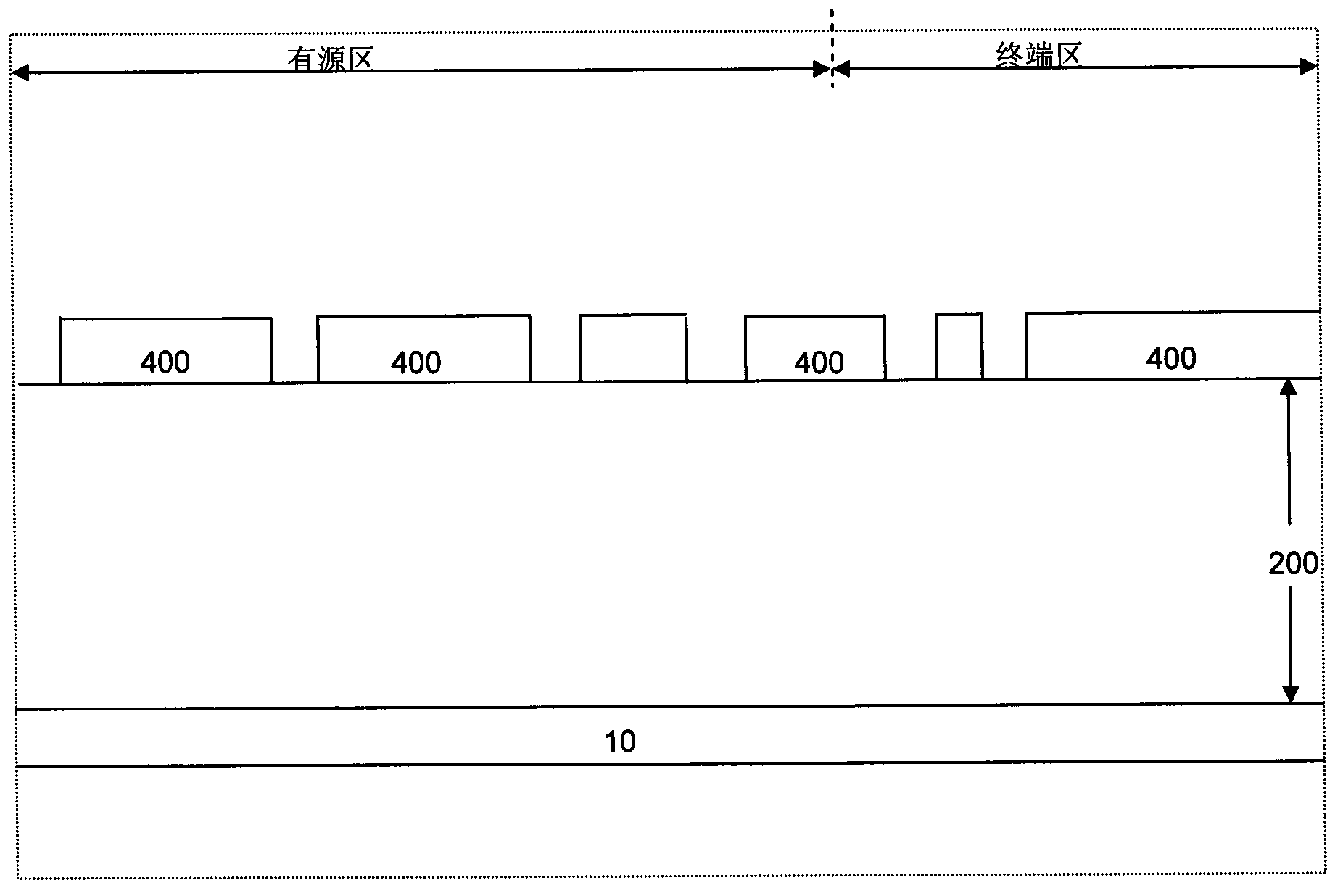

[0087] Such as figure 2 As shown, after dry etching the oxide layer exposed by patterning the trench mask, the epitaxial layer is exposed, and then the photolithographic coating is removed.

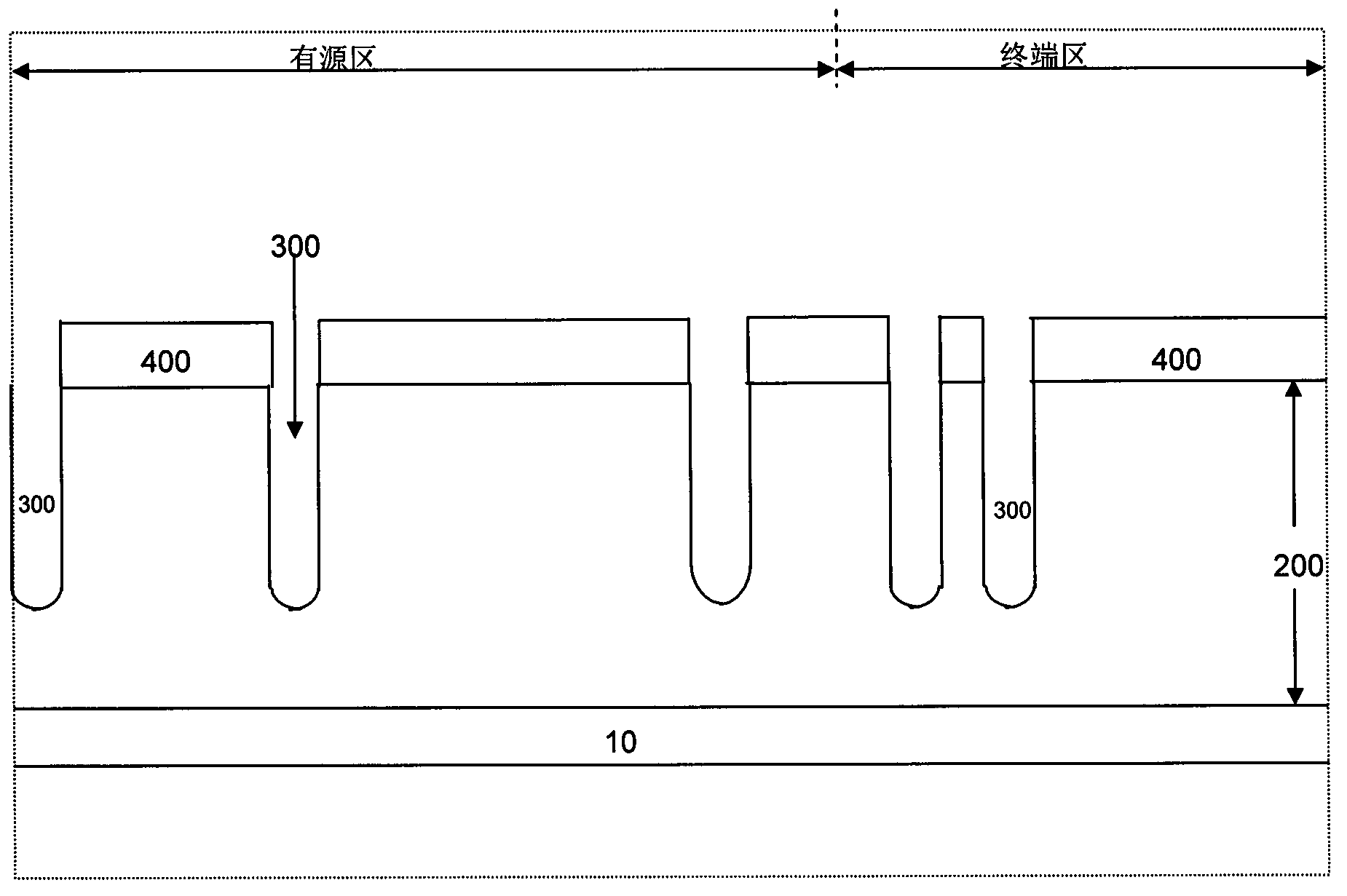

[0088] Such as image 3 As shown, a trench 300 is formed by etching, and the trench (0.8um to 5.0um in depth and 0.12um to 1.5um in width) extends to the N-type epitaxial layer.

[0089] Such as Figure 4 As shown, after the trench is formed, the trench is sacrificially oxidized (10 minutes to 100 minutes at a temperature of 1000°C to 1200°C) to eliminate the silicon layer damaged by the plasma during t...

Embodiment 2

[0100] It is an embodiment of the present invention.

[0101] Step and embodiment 1 are by Figure 1 to Figure 8 Same, then utilize the source region mask step to form the N-type source region 204, and the remaining steps are the same as in Embodiment 1 by Figure 10 to Figure 13 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com