Surface modified anode material for lithium ion battery and method

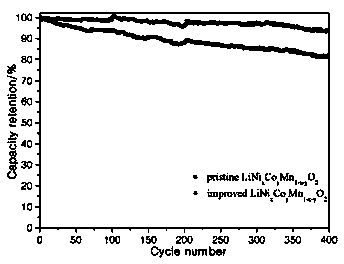

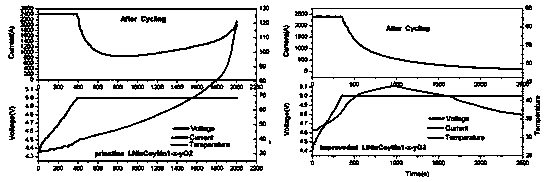

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve the problems affecting the high-current charge and discharge performance of positive electrode materials, and achieve the goal of overcoming the reduction of high-current charge and discharge performance, The effect of easy control and simple coating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

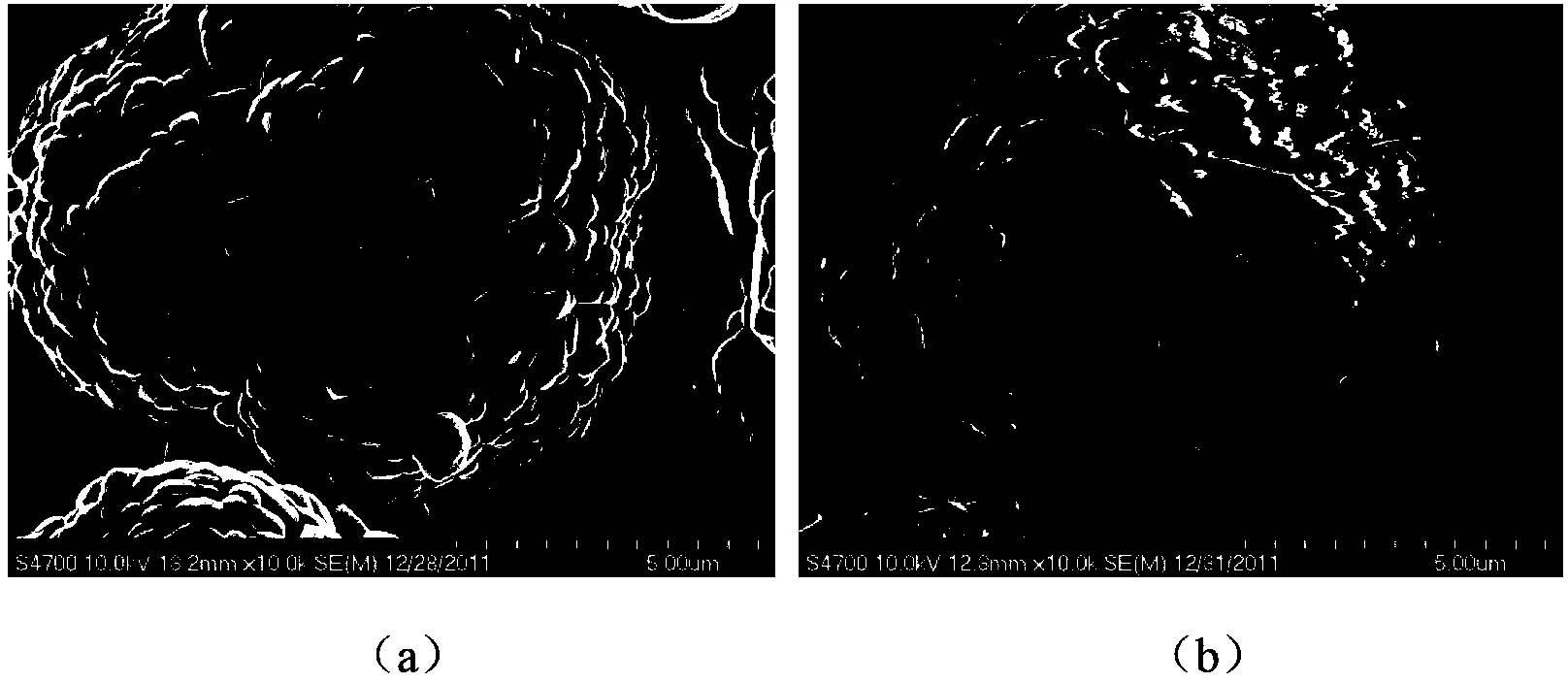

Embodiment 1

[0020] Example 1: Dissolve 4g of aluminum isopropoxide in 400mL of isopropanol, add 2.7g of citric acid and 100g of LiNi under stirring 1 / 3 co 1 / 3 mn 1 / 3 o 2 , continue to stir the reaction for 4h to fully hydrolyze the aluminum isopropoxide and adjust the pH value to form a sol to adsorb to LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 particle surface. Then the temperature was raised to 80°C, evaporated to dryness under stirring, and then the material was placed in a sintering furnace and kept at 300°C for 5 hours at a heating rate of 5°C / min. After cooling in the furnace, 1wt% alumina and 1wt% carbon composite coated LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Material.

Embodiment 2

[0023] Example 2: Dissolve 14.6g magnesium nitrate and 5.0g diammonium hydrogen phosphate in 50mL deionized water, gradually form a magnesium phosphate sol under stirring, then add 2g carbon nanotubes and adjust the pH value to form a sol adsorbed on 100gLiMn 2 o 4 material surface. After continuing to stir for 2 hours, transfer it to a 150°C oven for drying, then treat it at 600°C for 0.5h and sieve to obtain LiMn with 5wt% and 2wt% coatings of magnesium phosphate and carbon nanotubes, respectively. 2 o 4 Material.

Embodiment 3

[0024] Example 3: LiCoO 2 Disperse in a mixed solvent of ethanol and deionized water, where the volume ratio of ethanol and water is 1:1. Then add superconducting carbon black and polyvinylpyrrolidone under stirring, then add an aqueous solution of ammonium fluoride dropwise, react for 1 hour, dry at 100°C, and then heat treat at 500°C for 3 hours to obtain a composite coating of lanthanum fluoride and carbon LiCoO 2 Material. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com