Method for recovering sewage of artificial board production system

A production system, recycling technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high treatment cost, rising water in circulating water system, and large investment. , to achieve the effect of high heat utilization rate, low operating cost and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

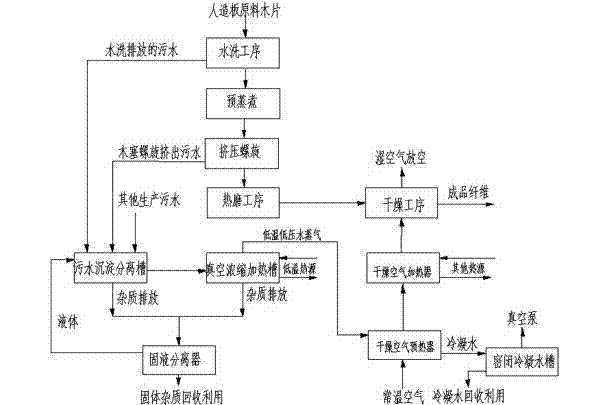

[0022] Embodiment one: with reference to attached figure 1 , the vacuum concentration heating tank of the present invention operates independently and is applied to a daily output of 500m 3 MDF production system with chip washing device.

[0023] The daily discharge of sewage in the wood chip washing process is 50m 3 , the daily sewage discharge volume of the cork screw is 30m 3 , the amount of other sewage is about 10m per day 3 , a total of about 90m 3 / day, hourly average sewage volume 3.75m 3 , the air volume of the drying fan is about 300000m 3 / h, separately set the air preheater on the air inlet side of the dry air heater.

[0024] In this embodiment, the flue gas from the biomass heat-conducting oil furnace of the wood-based panel production system is used as the heat source for the vacuum concentration heating tank, and the temperature of the flue gas is 150-180°C. -2.0KPa, the temperature rise of the dry air preheater is 20-25°C, the temperature of the recover...

Embodiment 2

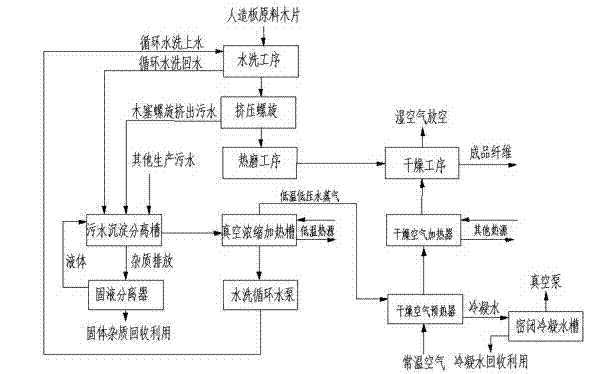

[0025] Embodiment two: with reference to attached figure 2 , the vacuum concentration heating tank of the present invention is connected to the water washing system in series, and is applied to a daily output of 500m 3 MDF production system with wood chip washing device.

[0026] 250-300m of circulating water in the wood chip washing process 3 / h, the daily sewage discharge volume of the cork screw is 30m 3 , the amount of other sewage is about 10m per day 3 , the hourly average sewage volume is 3-3.5m 3 , the air volume of the drying fan is about 300000m 3 / h, separately set the air preheater on the air inlet side of the dry air heater.

[0027]Solid caustic soda is used to adjust the pH value of circulating water to 8.5-9.0. The sewage vacuum concentration heating tank adopts the flue gas of the biomass heat conduction oil furnace of the wood-based panel production system as the heat source, and the temperature of the flue gas is 150-180 ° C. Control the vacuum concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com