Method for extracting sodium copper chlorophyll from silkworm excrement

A technology of chlorophyll copper sodium salt and silkworm sand, which is applied in the direction of organic chemistry, etc., can solve the problems of increasing the difficulty of chlorophyll extraction, increasing cost and time consumption, increasing environmental pollution, etc. economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

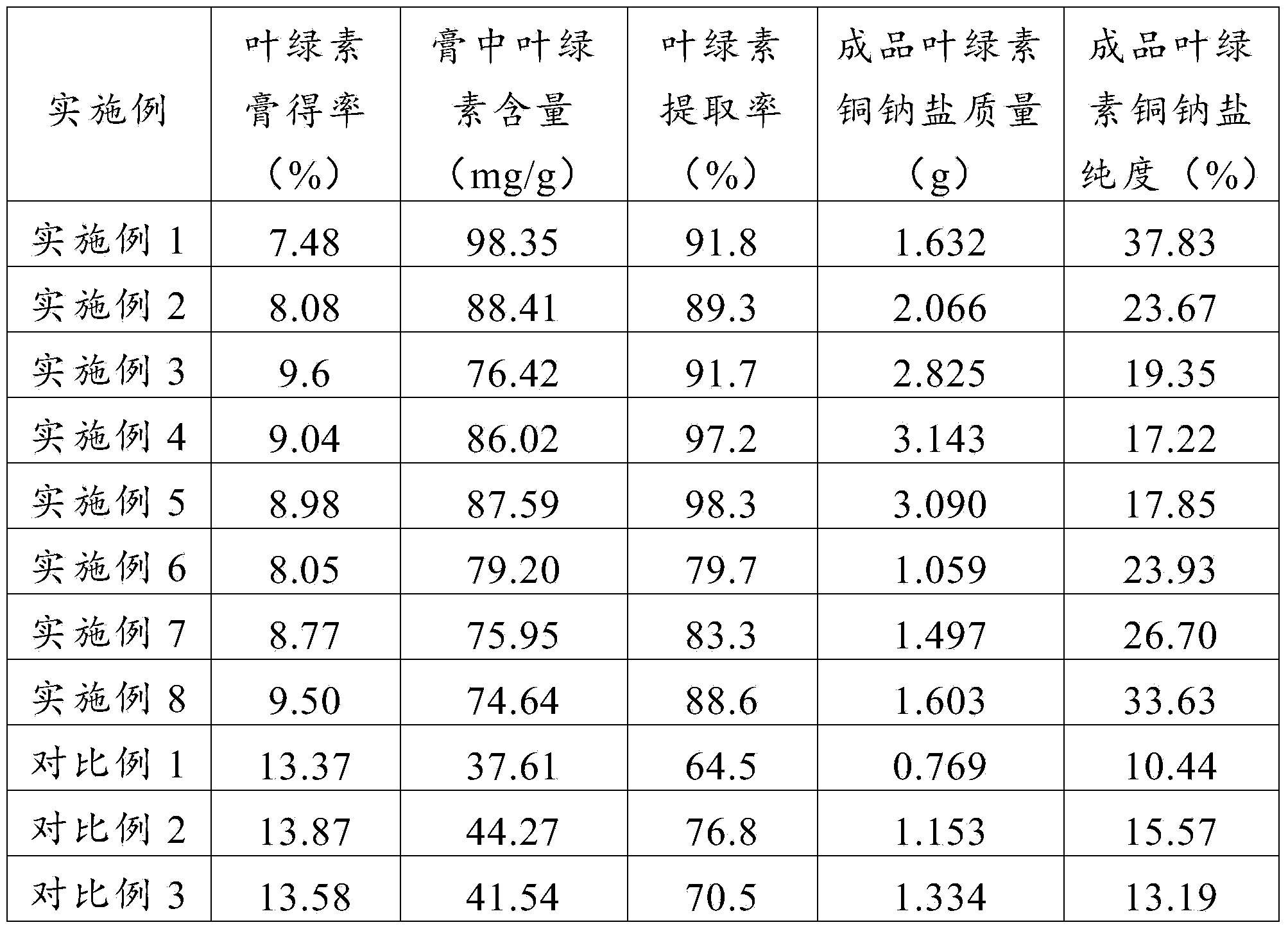

Embodiment 1

[0080] Present embodiment realizes with the silkworm excrement raw material of 5000g first silkworm age stage.

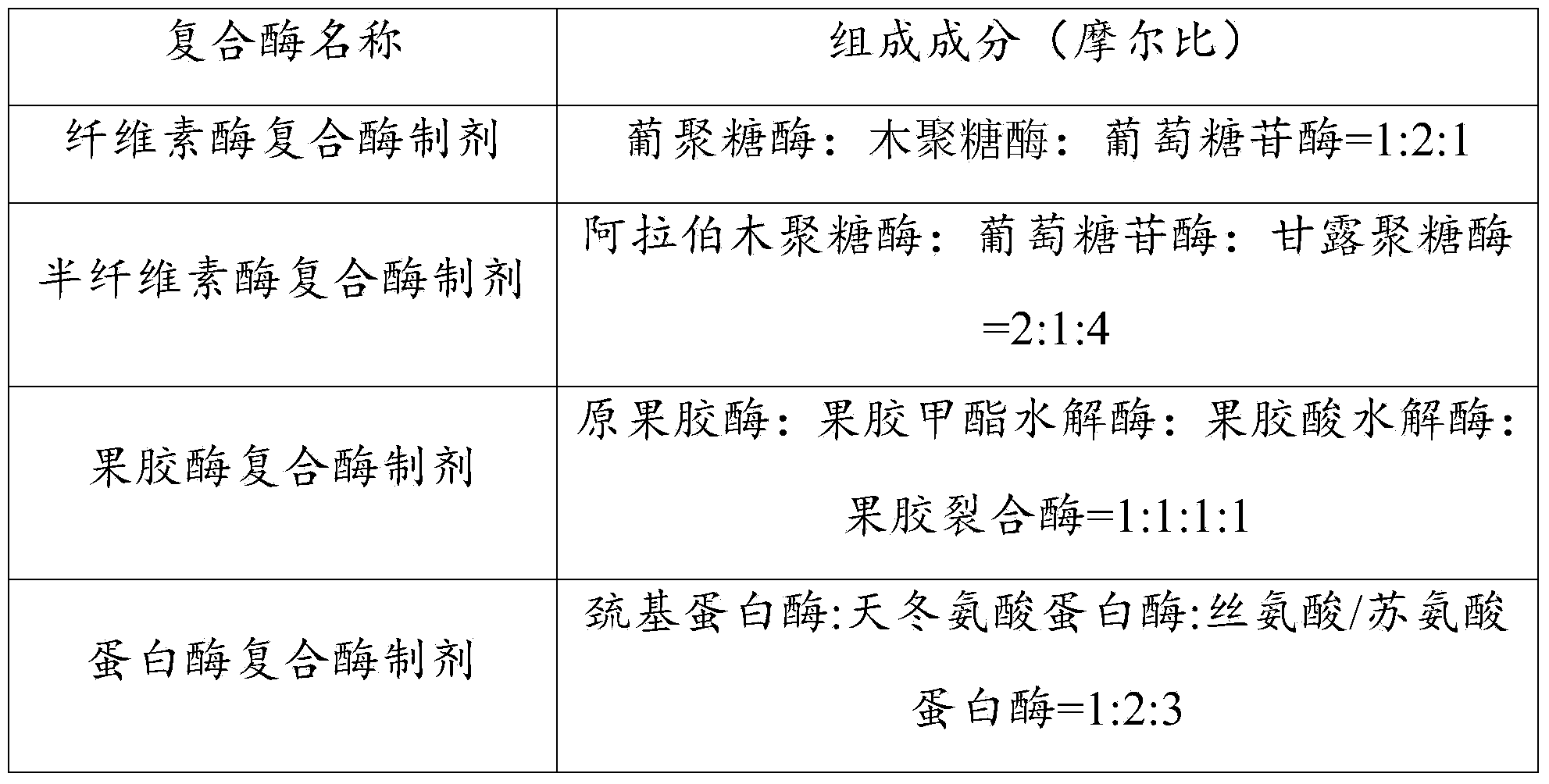

[0081] Precisely weigh 3.10g of cellulase compound enzyme preparation, 2.78g of hemicellulase compound enzyme preparation, 1.81g of pectinase compound enzyme preparation, and 0.46g of triacylglycerol acyl hydrolase, dissolve them in 3000g of 40°C water, and spray them on Into 5000g of crushed silkworm excrement powder, spray while stirring and mixing. After 1 hour, dissolve 2.13g of protease in water and spray it on the raw material. After stirring evenly, make it hydrolyze for 5 hours.

[0082] Enzymatic hydrolysis: put the silkworm excrement hydrolyzed for 5 hours in a constant temperature environment of 30°C for 6 hours, and stir in time during the reaction, so that the enzymatic hydrolysis reaction can fully proceed.

[0083]Granulation: Re-granulation is carried out after the reaction is completed. First, the muddy silkworm excrement with a water content of 65%...

Embodiment 2

[0088] Present embodiment realizes with the silkworm excrement raw material of 5000g second silkworm age stage.

[0089] Precisely weigh 4.82g of the pectinase compound enzyme preparation and 3.37g of the cellulase compound enzyme preparation and dissolve them in 3000g of 40°C water. After fully dissolving, spray them into 5000g of crushed silkworm excrement powder, and stir and mix evenly while spraying; 4.15g was dissolved in water, sprayed on the raw material and stirred for 3h.

[0090] Enzymatic hydrolysis: put the silkworm sand mud added with enzymes in a constant temperature environment of 30°C for 6 hours, and stir in time during the reaction, so that the enzymatic hydrolysis reaction can fully proceed.

[0091] Granulation: Re-granulation is carried out after the reaction is completed. First, the muddy silkworm excrement with a water content of 65% by weight is dried at a high speed for 5 minutes at 105°C until the water content of the silkworm excrement powder is 40%...

Embodiment 3

[0096] Present embodiment realizes with the silkworm excrement raw material of 5000g the third silkworm age stage.

[0097] Accurately weigh 3.10g of the cellulase compound enzyme preparation, 2.78g of the hemicellulase compound enzyme preparation, and 1.81g of the pectinase compound enzyme preparation and add them to 3000g of water. Stir to mix while spraying.

[0098] Enzymatic hydrolysis: put the silkworm sand mud added with enzymes in a constant temperature environment of 30°C for 6 hours, and stir in time during the reaction, so that the enzymatic hydrolysis reaction can fully proceed.

[0099] Granulation: Re-granulation is carried out after the reaction is completed. First, the muddy silkworm excrement with a water content of 65% by weight is dried at a high speed for 5 minutes at 105°C until the water content of the silkworm excrement powder is 40% by weight, and then high-speed granulation is used. Machine into particles with a diameter of 0.5 cm and a length of 1.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com