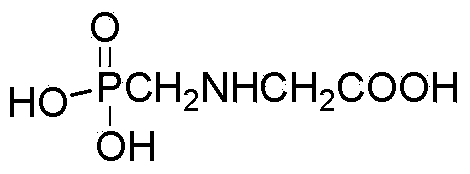

Method for producing glyphosate by comprehensively utilizing glycine crystallization mother liquor

A technology of crystallizing mother liquor and glycine, which is applied in the field of pesticides, can solve the problems of high equipment and catalyst requirements, difficult biochemical treatment, by-product formaldehyde, etc., and achieve social and economic benefits, simplification of reaction procedures, and reduction of material consumption and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

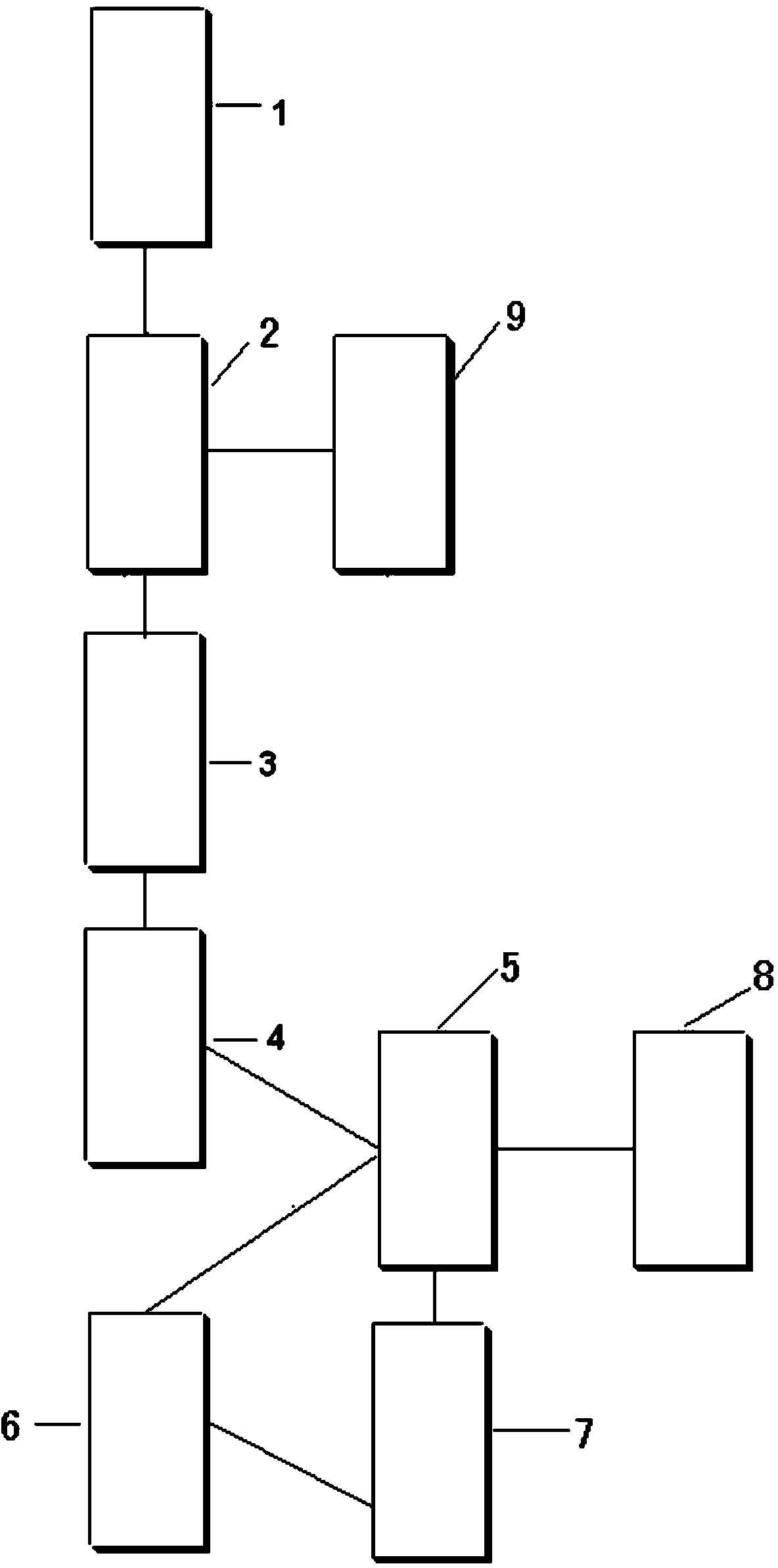

Method used

Image

Examples

Embodiment 1

[0041] Glycine crystallization mother liquor neutralization reaction, its concrete operation is as follows:

[0042] Weigh 507 grams of glycine crystallization mother liquor (wherein the content of glycine is 14%, and the content of iminodiacetic acid is 16%) and placed in a 2000mL four-necked flask equipped with a stirrer, a thermometer, a constant pressure dropping funnel, and a condenser, and then add 155 grams of 40% aqueous sodium hydroxide solution is heated and decompressed and the ammonia in the system is completely removed.

[0043] Chloroacetic acid is converted into sodium chloroacetate aqueous solution, and its concrete operation is as follows:

[0044] Weigh 100 grams of chloroacetic acid and place it in a 500mL beaker, add 300 grams of water, then slowly add 104 grams of 40% aqueous sodium hydroxide solution dropwise, and control the neutralization temperature not to exceed 60°C. After the dropwise addition, we get Sodium chloroacetate in water.

[0045] Slowly...

Embodiment 2

[0051] Glycine crystallization mother liquor neutralization reaction, its concrete operation is as follows:

[0052] Weigh 507 grams of glycine crystallization mother liquor (the content of glycine is 14%, the content of iminodiacetic acid is 16%) and put it in a 2000mL four-neck flask equipped with stirrer, thermometer, constant pressure dropping funnel and condenser, and then add 40 % sodium hydroxide aqueous solution 155 grams, the ammonia in the system is completely removed by heating and decompression.

[0053] Chloroacetic acid is converted into sodium chloroacetate aqueous solution, and its concrete operation is as follows:

[0054] Weigh 100 grams of chloroacetic acid and place it in a 500mL beaker, add 300 grams of water, then slowly add 104 grams of 40% aqueous sodium hydroxide solution dropwise, and control the neutralization temperature not to exceed 60°C. After the dropwise addition, we get Sodium chloroacetate in water.

[0055] Slowly add the obtained sodium c...

Embodiment 3

[0061] The neutralization reaction of glycine crystallization mother liquor, its concrete operation is as follows:

[0062] Weigh 507 grams of glycine crystallization mother liquor (the content of glycine is 14%, the content of iminodiacetic acid is 16%) and place it in a 2000mL four-necked flask equipped with a stirrer, thermometer, constant pressure dropping funnel and condenser, and then add 40 % sodium hydroxide aqueous solution 155 grams, the ammonia in the system is completely removed by heating and decompression.

[0063] Chloroacetic acid is converted into sodium chloroacetate aqueous solution, and its concrete operation is as follows:

[0064] Weigh 100 grams of chloroacetic acid and place it in a 500mL beaker, add 300 grams of water, then slowly add 104 grams of 40% aqueous sodium hydroxide solution dropwise, and control the neutralization temperature not to exceed 60°C. After the addition is completed, we get Sodium chloroacetate in water.

[0065] Slowly add the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com