Method for preparing non-polar zinc oxide thin film on silicon-based substrate

A non-polar, thin-film technology, applied in the field of functional material preparation, can solve the problems of increased energy consumption, high turn-on voltage, unfavorable electrical conductivity, etc., and achieve the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

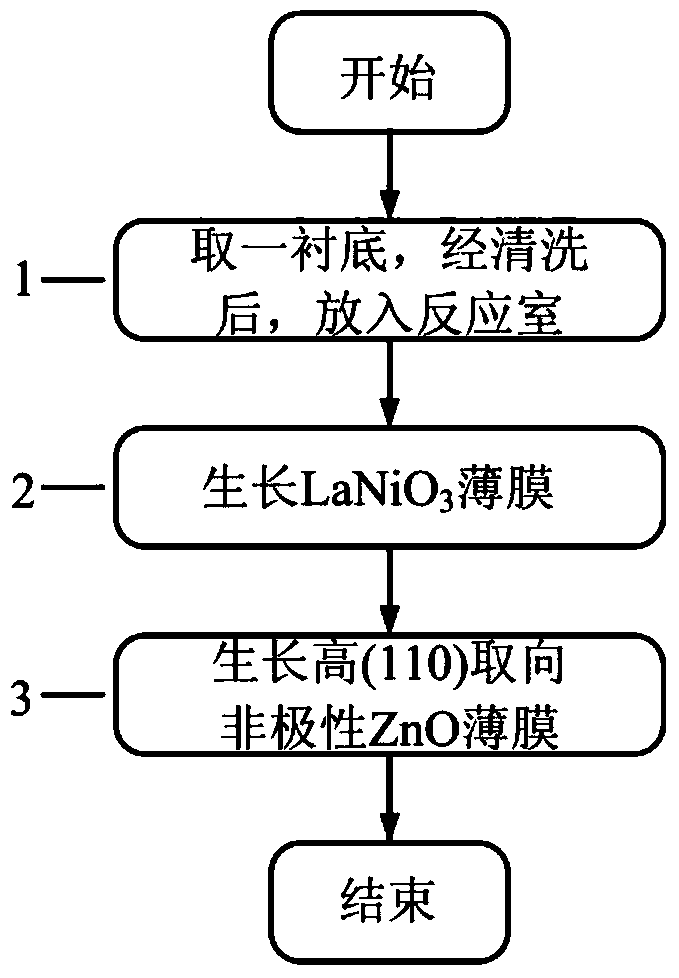

Method used

Image

Examples

Embodiment 1

[0035] (1) Take one (100) crystal-oriented single-crystal Si wafer substrate, use ultrasonic cleaning, wash in acetone, ethanol and deionized water for 10 minutes, and then dry it with nitrogen gas for later use;

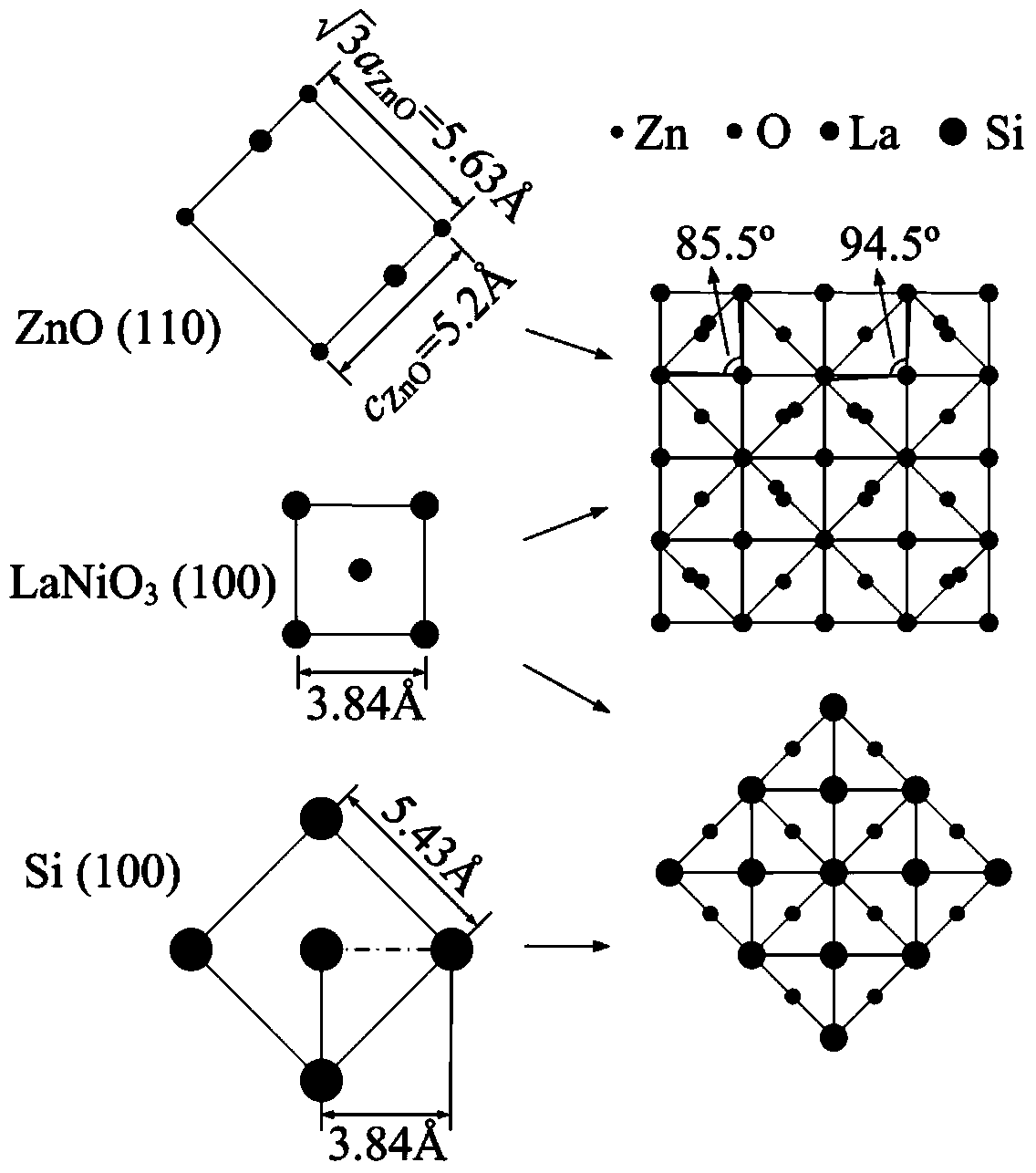

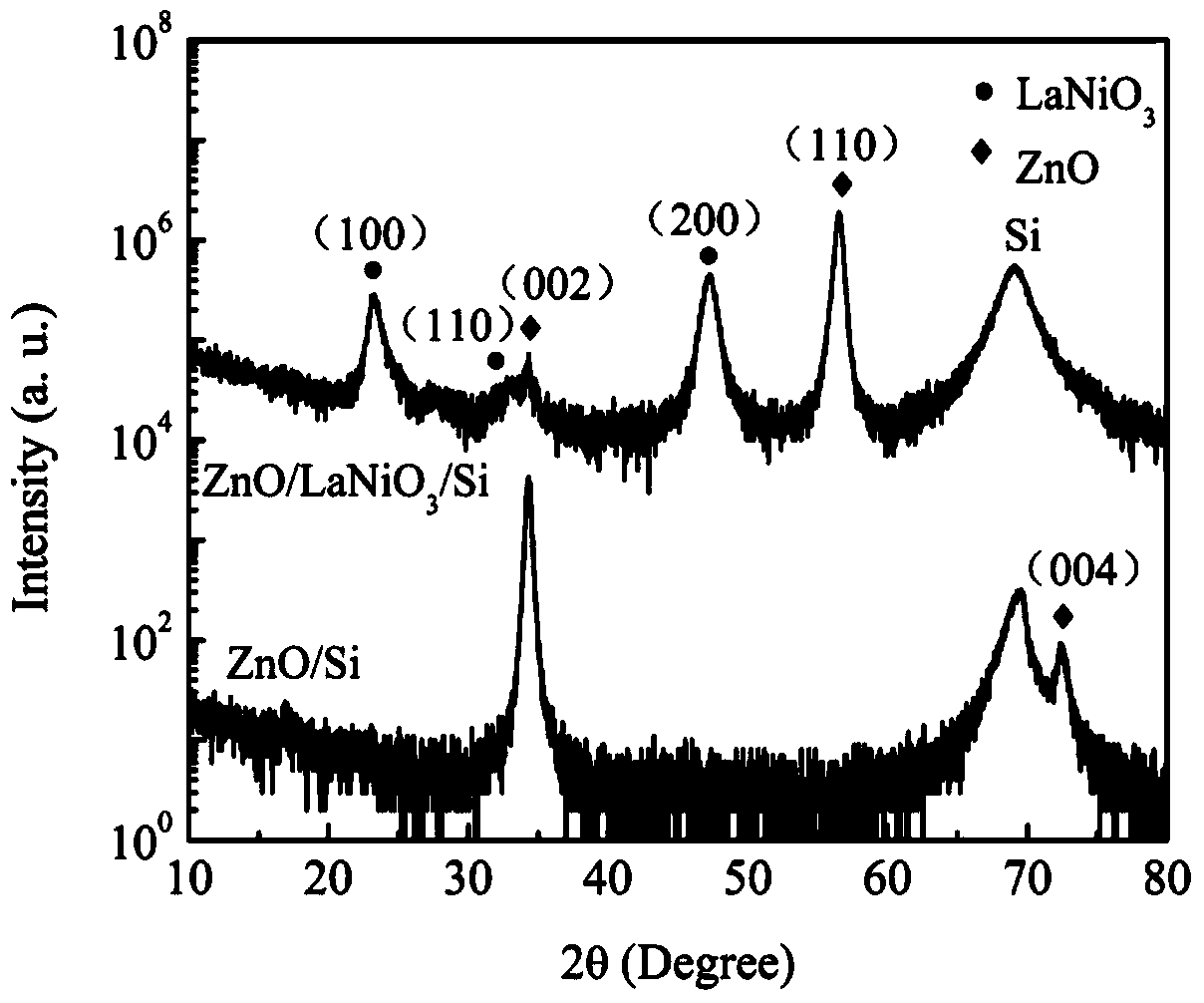

[0036] (2) Before the experiment starts, the vacuum degree of the reaction chamber is controlled to be 8×10 -4 Below Pa, the speed of the sputtering table is maintained at 15rad / s; first, the (100) Si substrate is heated to 300°C, and the purity is 99.99% LaNiO 3 Ceramic target pre-sputtering 30min, working gas Ar and O 2 The flow ratio is 1:4, the sputtering power and working pressure are controlled to be 250W and 0.5Pa, respectively, after sputtering for 60min, take it out, and anneal at 700°C for 30min to obtain LaNiO with a layer thickness of 90nm. 3 Conductive film;

[0037] (3) Before the experiment starts, the vacuum degree of the reaction chamber is controlled to be 8×10 -4 Below Pa, the speed of the sputtering table is maintained at 15rad / s; the (100) or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com