Neodymium-iron-boron magnet and preparation method thereof

A technology of neodymium iron boron and magnets, which is applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of reduced magnetic properties at room temperature, increased processes, increased production costs, etc., and achieves the reduction of heavy rare earth content and reduction Production cost, effect of working temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

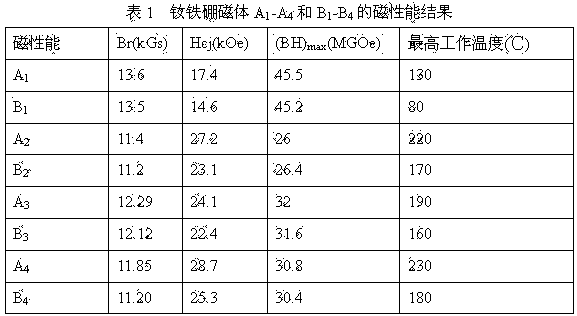

Examples

Embodiment 1

[0034] The chemical formula of the NdFeB matrix alloy in this embodiment is Nd 24.5 PR 6 Dy 2 Fe 68.4 Cu 0.1 B 1.03 , The doping amounts of tin and aluminum are respectively 0.15% and 0.3% of the weight of the NdFeB matrix alloy.

[0035] Preparation: including the following steps: the raw material with a purity greater than 99% is Nd according to the nominal composition 24.5 PR 6 Dy 2 Fe 68.4 Cu 0.1 B 1.03 Proportioning is carried out, and NdFeB alloy flakes with a thickness of 0.25-0.35mm are made by using the quick-setting and spinning process, and powders with an average particle size of 3-5μm are made by the "hydrogen crushing + jet milling" process, and after hydrogen crushing , adding 0.3% antioxidant before the jet mill; adding tin and aluminum nanoparticles with an average particle size of 100nm to the NdFeB matrix alloy powder, the doping ratios of tin and aluminum are respectively 0.15% by weight of the matrix alloy % and 0.3%, mixed in the mixer for 4 ho...

Embodiment 2

[0037] The chemical formula of the NdFeB matrix alloy in this embodiment is Nd 27 Dy 6 Fe 65.6 Nb 0.25 Cu 0.15 B 1.1 , The doping ratios of tin and aluminum are respectively 0.15% and 0.4% of the weight of the NdFeB matrix alloy.

[0038] The preparation method of NdFeB magnet comprises the following steps: the raw material whose purity is greater than 99% is Nd according to the nominal composition 27 Dy 6 Fe 65.6 Nb 0.25 Cu 0.15 B 1.1 Ratio, use the quick-setting stripping process to make NdFeB alloy flakes with a thickness of 0.25-0.35mm; use the "hydrogen crushing + jet mill" process to grind NdFeB alloy flakes into powders with an average particle size of 3-5um , and after hydrogen crushing and before jet milling, an antioxidant with an addition amount of 0.30 wt % is added; tin and aluminum nanoparticles with an average particle diameter of 200nm are added to the NdFeB matrix alloy powder, tin, The doping ratio of aluminum is 0.15% and 0.4% by weight of the bas...

Embodiment 3

[0040] The chemical formula of the NdFeB matrix alloy in this embodiment is Nd 20 PR 7 Dy 4 Fe 67.07 Ga 0.4 Nb 0.3 Cu 0.2 B 1.03 , The doping ratios of tin and aluminum are respectively 0.15% and 0.2% of the weight of the NdFeB matrix alloy.

[0041] The preparation method of NdFeB magnets comprises the following steps: raw materials with a purity greater than 99% are added according to the nominal composition Nd 20 PR 7 Dy 4 Fe 67.07 Ga 0.4 Nb 0.3 Cu 0.2 B 1.03 Ratio, use the quick-setting stripping process to make NdFeB alloy flakes with a thickness of 0.25-0.35mm; use the "hydrogen crushing + jet mill" process to grind NdFeB alloy flakes into powders with an average particle size of 3-5um , and after hydrogen crushing and before jet milling, an antioxidant with an addition amount of 0.30 wt % is added; tin and aluminum nanoparticles with an average particle diameter of 200nm are added to the NdFeB matrix alloy powder, tin, The doping ratio of aluminum is 0.15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com