Production technology for concentrating raw material extract of traditional Chinese medicine preparation of anti-inflammation and cholagogic tablet

A technology for Xiaoyanlidan tablets and traditional Chinese medicine preparations is applied in the directions of plant raw materials, non-central analgesics, medical raw materials derived from angiosperm subphylum, etc., and can solve the problems of high production cost, long production time, low quality of extracts and the like , to reduce high temperature degradation damage, reduce steam supply load, and improve the quality of drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

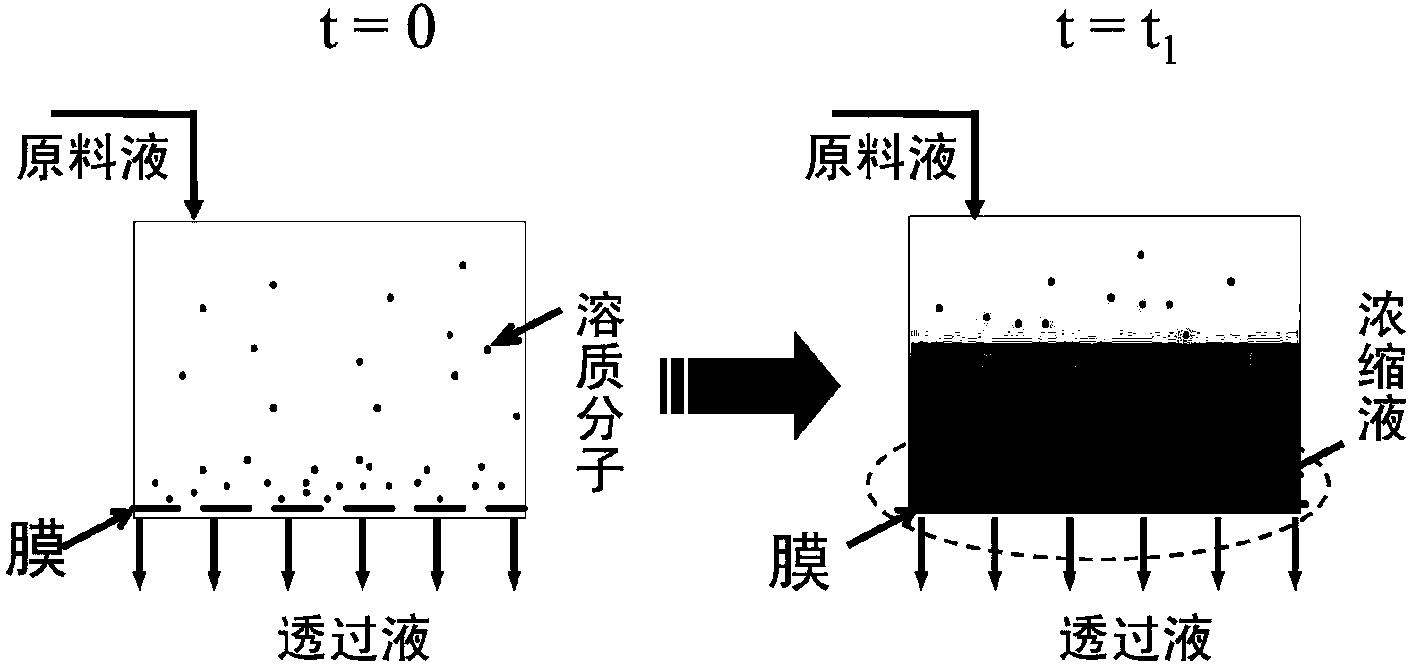

Method used

Image

Examples

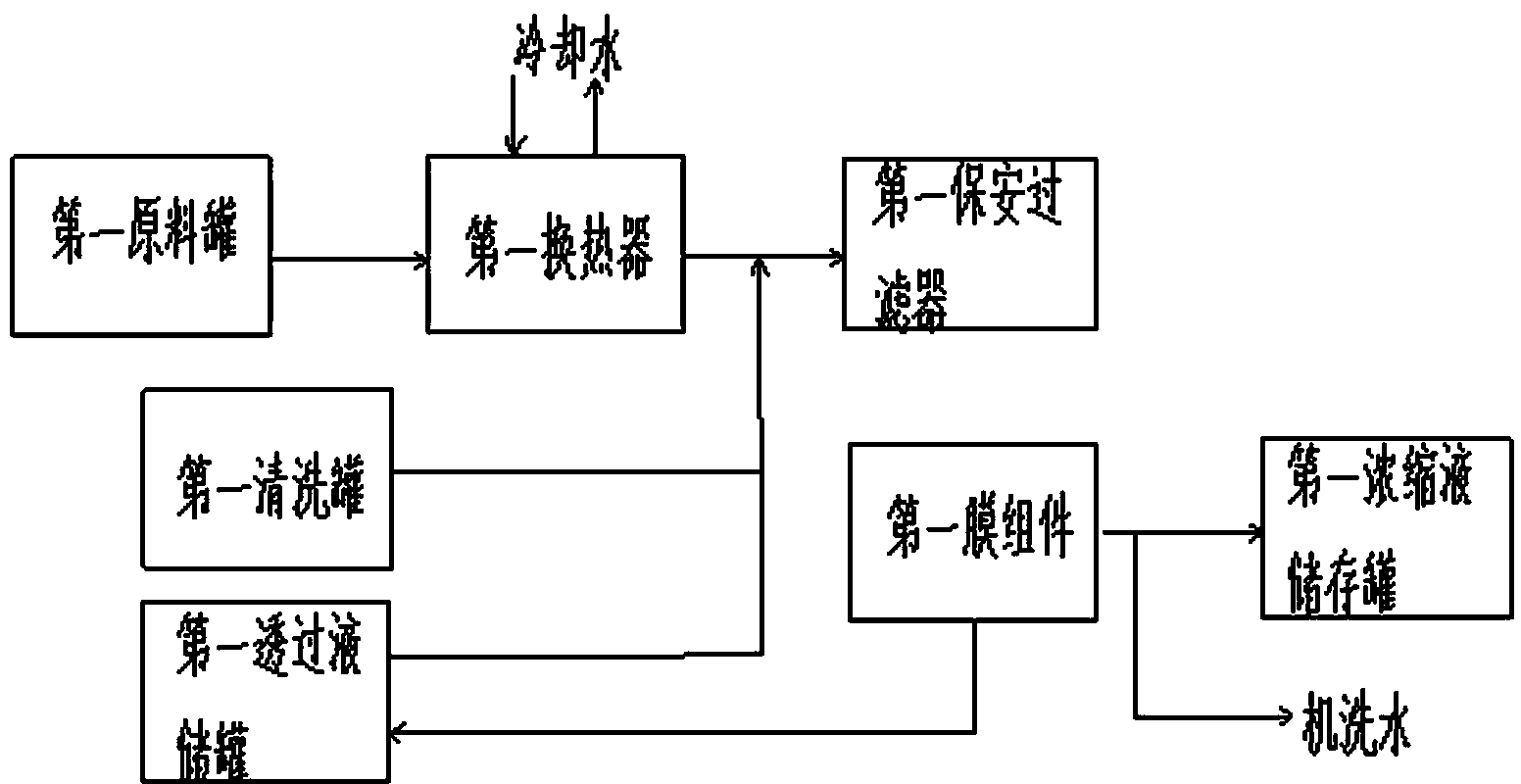

Embodiment 1

[0050] Xiaoyan Lidan Tablets are composed of three Chinese herbal medicines: Andrographis paniculata, Bitterwood, and Xihuangcao. Andrographis paniculata and bitter wood are heated and extracted twice with 80% to 85% ethanol, each time for 2 hours, the extract is cooled by a plate heat exchanger, filtered, and the filtrate is combined, and the DK series nanofiltration separation membrane is used to pre-concentrate through membrane separation equipment , the concentration of the alcohol extract during membrane separation is 0.6% solid content, the operating temperature is 30°C, and the operating pressure is 1.6MPa. The separated permeate is the solvent (ethanol solution) in the extract, which can be used for the extraction and feeding of the same species. After membrane separation, the drug-containing concentrate is recovered by vacuum distillation equipment to recover the remaining ethanol, and concentrated into a thick paste. Xihuangcao is decocted twice with water. The decoc...

Embodiment 2

[0052] Xiaoyan Lidan Tablets are composed of three Chinese herbal medicines: Andrographis paniculata, Bitterwood, and Xihuangcao. Andrographis paniculata and bitter wood are heated and extracted twice with 80% to 85% ethanol, each time for 2 hours, the extract is cooled by a plate heat exchanger, filtered, and the filtrates are combined, and the low-pressure reverse osmosis separation membrane in the reverse osmosis membrane is used to separate through the membrane. The equipment is pre-concentrated. During membrane separation, the concentration of the alcohol extract is 0.8% solid content, the operating temperature is 36°C, and the operating pressure is 2.6MPa. The separated permeate is the solvent (ethanol solution) in the extract, which can be used for the same variety Extraction and feeding, the drug-containing concentrated liquid after membrane separation is recovered by vacuum distillation equipment to recover the remaining ethanol, and concentrated into a thick paste....

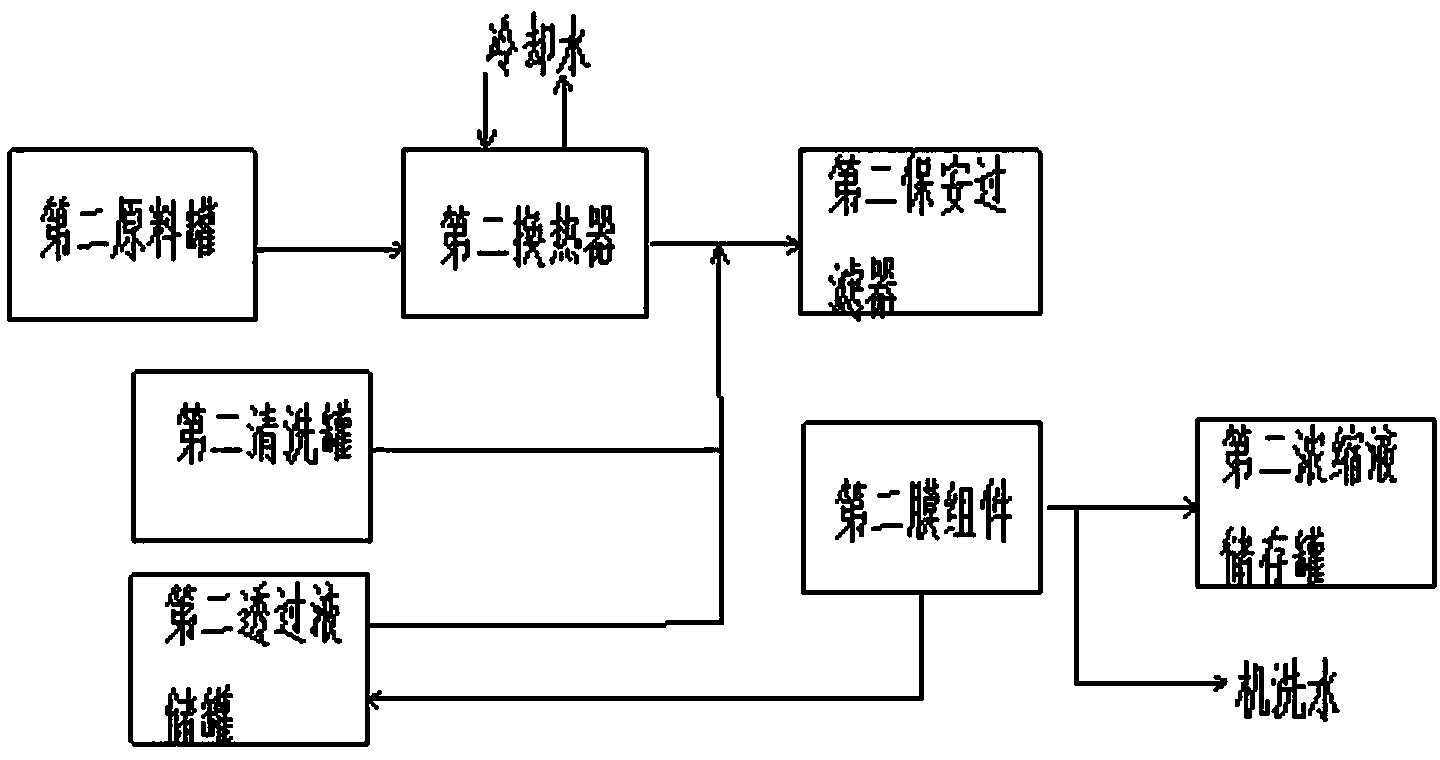

Embodiment 3

[0054] Xiaoyan Lidan Tablets are composed of three Chinese herbal medicines: Andrographis paniculata, Bitterwood, and Xihuangcao. Andrographis paniculata and bitter wood are heated and extracted twice with 80%-85% ethanol, each time for 2 hours, the extract is cooled by a plate heat exchanger, filtered, the filtrate is combined, and the DL series nanofiltration separation membrane is used to pre-concentrate through membrane separation equipment , the concentration of the alcohol extract during membrane separation is 1.2% solid content, the operating temperature is 23°C, and the operating pressure is 3.0MPa. Extraction and feeding, and the drug-containing concentrated liquid obtained from the two membrane separations are all recovered by vacuum distillation equipment to recover the remaining ethanol and concentrated into a thick paste. Xihuangcao is decocted twice with water. The decoction is cooled by a plate heat exchanger, filtered, and the filtrates are combined. A low-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com