Method for improving whiteness of sodium thiocyanate in coking desulfurization waste liquid

A technology of coking desulfurization waste liquid and sodium thiocyanate, which is applied in the direction of thiocyanate, etc., can solve the problems of low whiteness, unsatisfactory sodium thiocyanate, yellowing of sodium thiocyanate, etc., and achieve high whiteness and easy operation Convenience, the effect of reducing emissions and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, work flow, and use methods of the present invention achieve the purpose and effect easily understood, the present invention will be further described below in conjunction with specific embodiments.

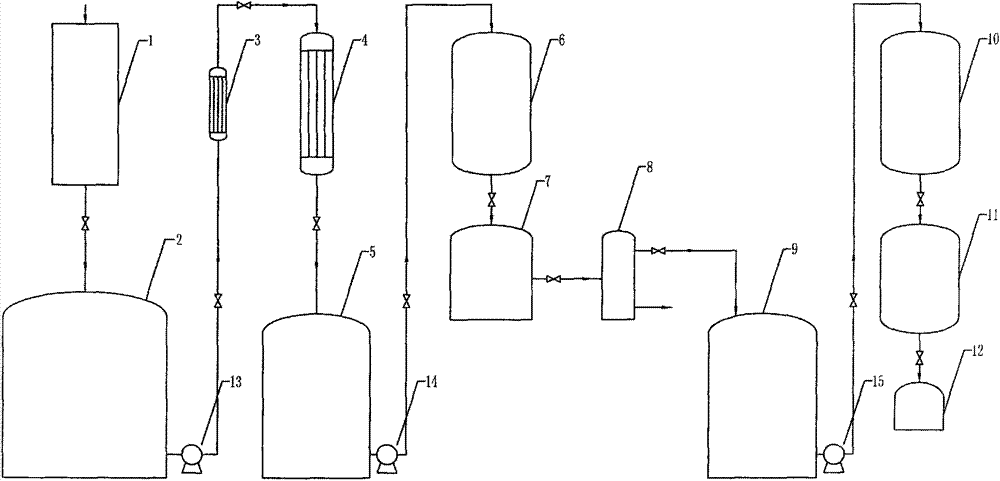

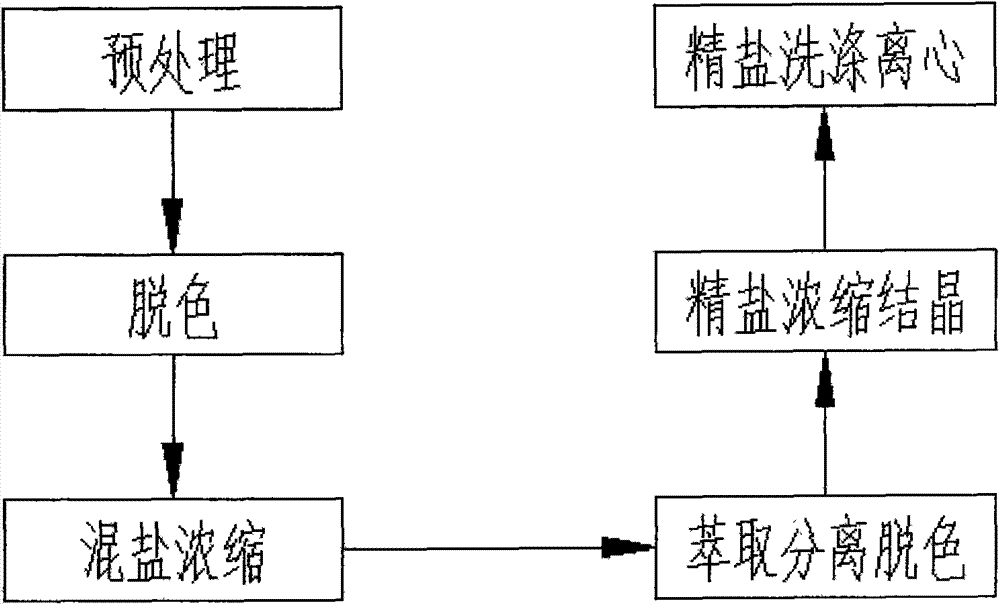

[0019] Such as figure 1 As shown, a device for improving the whiteness of sodium thiocyanate in coking desulfurization waste liquid, including a plate and frame filter press 1, a desulfurization liquid recovery tank 2, a preheater 3, a decolorization tower 4, and a decolorization clear liquid tank connected in sequence 5. Mixed salt evaporator 6, mixing tank 7, settling tank 8, refined salt clear liquid tank 9, refined salt evaporator 10, refined salt crystallization kettle 11, centrifuge 12, desulfurization liquid recovery tank 2 and preheater 3 A clear liquid pump 13, a decolorization pump 14 is provided between the mixed salt evaporator 6 and the mixing tank 7, and a refined salt pump 15 is provided between the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com