Catalyst component applied to olefin polymerization, preparation method thereof, catalyst for olefin polymerization and application of catalyst

A technology for olefin polymerization and catalysts, which is applied in the field of olefin polymerization catalysts and can solve problems such as poor stereospecificity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

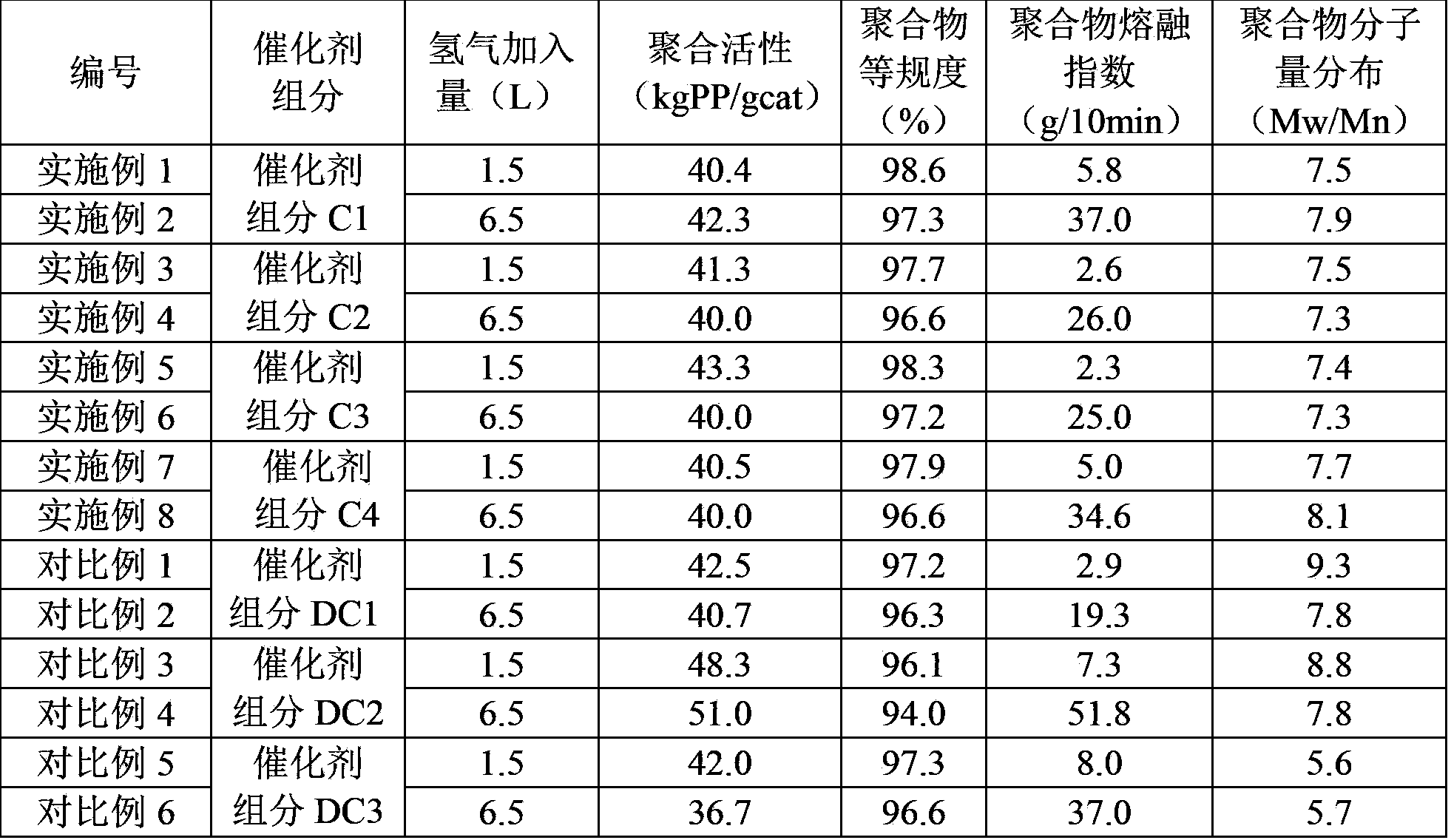

Examples

preparation example Construction

[0033] According to the present invention, the magnesium source can be various magnesium-containing compounds that can be used as catalysts for olefin polymerization, for example, the magnesium source can be magnesium halide, magnesium alcoholate or haloalcoholate, magnesium halide adduct carrier etc. The magnesium halide can be, for example, magnesium chloride and / or magnesium bromide; the magnesium alcoholate, for example, can be diethoxymagnesium; the magnesium halide alcoholate, for example, can be ethoxymagnesium chloride; The type of magnesium halide adduct carrier is known to those skilled in the art, for example, the magnesium halide adduct carrier disclosed in patents such as CN1091748A, CN101050245A, CN101486722A, 201110142357.X, 201110142156.X and 201110142024.7, and these patents disclosed The relevant content is fully incorporated in this application by reference. The specific preparation method of the magnesium halide adduct carrier may include the following ste...

Embodiment 1

[0052] This example is used to illustrate the catalyst component for olefin polymerization and its preparation method, the catalyst for olefin polymerization and its application provided by the present invention.

[0053] (1) Preparation of catalyst components for olefin polymerization:

[0054] In a 300ml glass reaction bottle, add 90ml of titanium tetrachloride and cool to -20°C, add 8 grams of magnesium halide carrier (prepared according to the method disclosed in CN1330086A Example 1), then heat up to 110°C, and Add 0.0003 mol of tributyl phosphate and 0.015 mol of 4-ethyl-3,5-heptanediol dibenzoate during the heating process, maintain at 110°C for 30 minutes, filter off the liquid, and then add tetrachloro Titanium dioxide was washed twice, and finally washed five times with hexane, and vacuum-dried to obtain catalyst component C1 for olefin polymerization. Using a grating spectrophotometer, detect the titanium element content in the catalyst component according to spect...

Embodiment 2

[0058] This example is used to illustrate the catalyst component for olefin polymerization and its preparation method, the catalyst for olefin polymerization and its application provided by the present invention.

[0059] Catalyst components for olefin polymerization and propylene polymerization were prepared according to the method in Example 1, except that the amount of hydrogen added during the propylene polymerization was 6.5 L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com