A kind of vinyl acetate-ethylene-tertiary carbonic acid vinyl ester copolymer emulsion and synthetic method

A technology of vinyl tertiary carbonate and vinyl acetate, which is applied in the field of vinyl acetate-ethylene-vinyl tertiary carbonate copolymer emulsion and synthesis, can solve the problems of lack of tertiary copolymer emulsion of tertiary carbonate and ethylene, lack of development of vinyl acetate, etc. Achieve the effect of low residual monomer, easy industrial production, and lower film forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

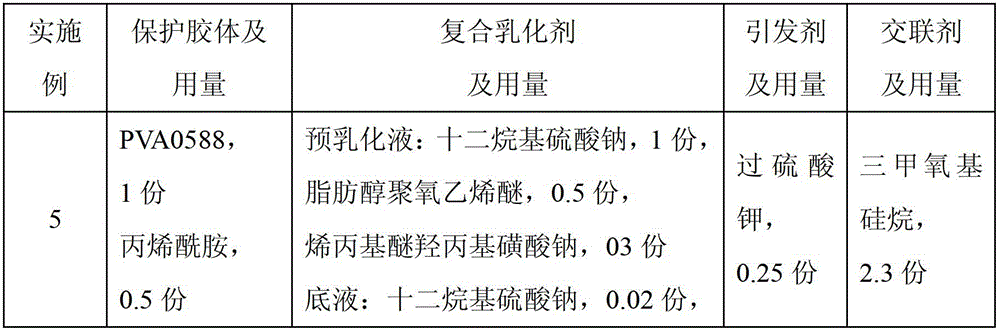

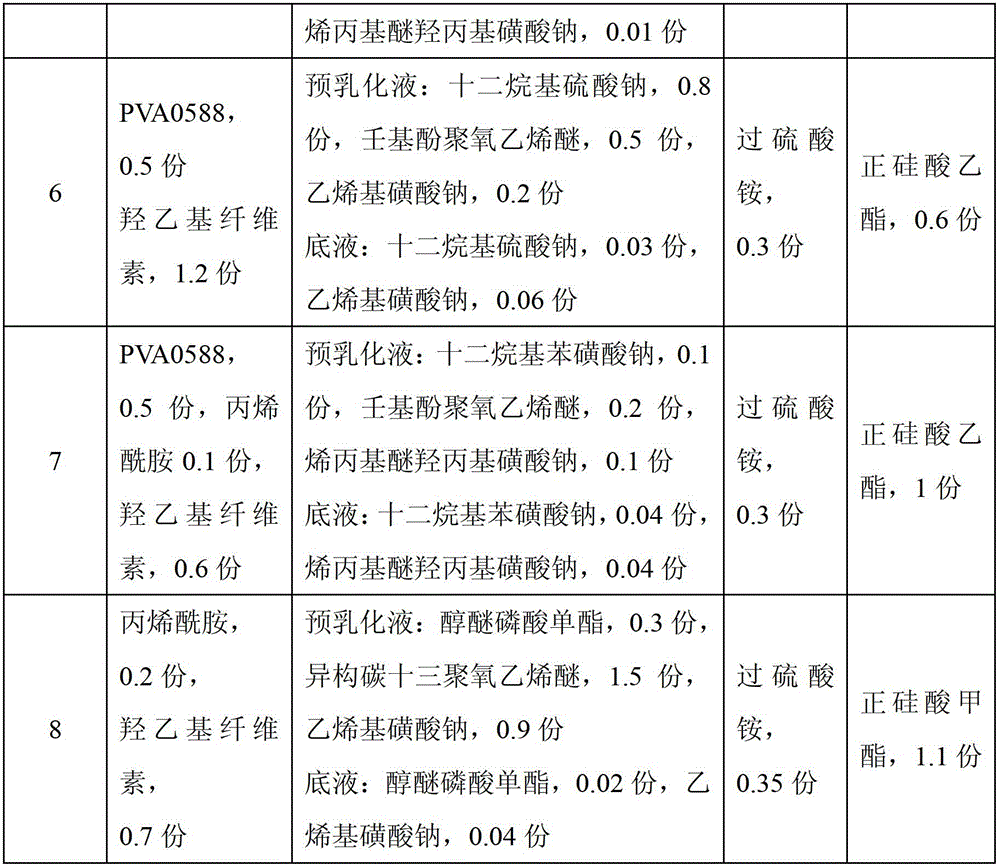

Examples

Embodiment 1

[0039] A vinyl acetate-ethylene-ethylene tertiary carbonate copolymer emulsion, which comprises the following raw material components, calculated in parts by mass: monomers: 45 parts of vinyl acetate, 6 parts of ethylene, 10 parts of ethylene tertiary carbonate, and 0.40 parts of compound emulsifier parts, 1 part of protective colloid, 0.1 part of initiator, 0.5 part of cross-linking agent, and 55 parts of water.

[0040] Among them, the composite emulsifier adopts 0.21 part of anionic emulsifier alcohol ether phosphoric acid monoester, 0.15 part of non-ionic emulsifier nonylphenol polyoxyethylene ether, and 0.04 part of reactive emulsifier sodium vinyl sulfonate; protective colloid adopts PVA0588 polyvinyl alcohol 1 0.1 part of ammonium persulfate was used as the initiator; 0.5 part of methyl orthosilicate was used as the cross-linking agent.

[0041] The vinyl acetate-ethylene-ethylene tertiary ethylene carbonate copolymer emulsion synthesized according to the components com...

Embodiment 2

[0050] A vinyl acetate-ethylene-vinyl tertiary carbonate copolymer emulsion, comprising the following raw material components, calculated in parts by mass: monomers: 70 parts of vinyl acetate, 15 parts of ethylene, 30 parts of ethylene tertiary carbonate, and 2.5 parts of a composite emulsifier. parts, 2.5 parts of protective colloid, 0.3 parts of initiator, 2.5 parts of cross-linking agent, and 55 parts of water.

[0051] Among them, the composite emulsifier adopts 1.03 parts of anionic emulsifier sodium lauryl sulfate, 1 part of non-ionic emulsifier fatty alcohol polyoxyethylene ether, and 0.47 part of reactive emulsifier sodium vinyl sulfonate; the protective colloid adopts 2.5 parts of acrylamide; The initiator is 0.3 part of potassium persulfate; the cross-linking agent is 2.5 parts of ethyl orthosilicate.

[0052] The vinyl acetate-ethylene-ethylene tertiary ethylene carbonate copolymer emulsion synthesized according to the components comprises the following steps:

[0...

Embodiment 3

[0060] A vinyl acetate-ethylene-ethylene tertiary carbonate copolymer emulsion, which comprises the following raw material components, in parts by mass: monomers: 60 parts of vinyl acetate, 10 parts of ethylene, 20 parts of ethylene tertiary carbonate, and 2.38 parts of a composite emulsifier parts, 1.5 parts of protective colloid, 0.2 parts of initiator, 2 parts of cross-linking agent, and 60 parts of water.

[0061] Among them, the composite emulsifier adopts 1.23 parts of anionic emulsifier sodium dodecyl benzene sulfonate, 0.8 part of nonionic emulsifier isocarbon tridecethoxyethylene ether, and 0.35 part of reactive emulsifier sodium vinyl sulfonate; protective colloid adopts 0.5 part of acrylamide, 1 part of hydroxyethyl cellulose; 0.2 part of potassium persulfate as initiator; 2 parts of trimethoxysilane as cross-linking agent.

[0062] The vinyl acetate-ethylene-ethylene tertiary ethylene carbonate copolymer emulsion synthesized according to the components comprises th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com