Ethylene-propylene-diene monomer rubber seal ring

A technology of EPDM rubber and sealing rubber ring, which is applied in the field of rubber preparation, can solve the problems of lack of electrical insulation and chemical medium corrosion resistance, weather resistance, ozone resistance, poor heat resistance, medium and environmental pollution, etc. Achieve good electrical insulation and chemical medium corrosion resistance, enhanced heat resistance, and simple composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An EPDM sealing rubber ring, the components of which are calculated in parts by weight: 100 parts of EPDM rubber, 1.2 parts of sulfur, 2.6 parts of accelerator CZ, 3.5 parts of zinc oxide, and 0.5 parts of stearic acid , 70 parts of carbon black, 75 parts of light calcium, 35 parts of naphthenic oil, 1 part of anti-aging agent 4010NA, and 1 part of anti-scorch agent CTP. After the above-mentioned components are subjected to conventional rubber preparation methods, that is, mixing, extrusion and vulcanization processes, the finished EPDM sealing rubber ring is obtained, and its performance tests are shown in Table 1.

Embodiment 2

[0019] A kind of EPDM sealing rubber ring, its components are counted as follows in parts by weight: 140 parts of EPDM rubber, 1.2 parts of sulfur, 2.6 parts of accelerator, 3.5 parts of zinc oxide, 1 part of stearic acid, carbon 63 parts of black, 75 parts of light calcium, 20 parts of naphthenic oil, 1 part of anti-aging agent 4010NA and 1 part of anti-scorch agent CTP. After the above-mentioned components are subjected to conventional rubber preparation methods, that is, mixing, extrusion and vulcanization processes, the finished EPDM sealing rubber ring is obtained, and its performance tests are shown in Table 1.

Embodiment 3

[0021] An EPDM sealing rubber ring, the components of which are calculated in parts by weight: 195 parts of EPDM rubber, 1.2 parts of sulfur, 2.6 parts of accelerator DM, 3.5 parts of zinc oxide, and 2 parts of stearic acid , 60 parts of carbon black, 75 parts of light calcium, 10 parts of naphthenic oil, 1 part of anti-aging agent D, and 1 part of anti-scorch agent CTP. After the above-mentioned components are subjected to conventional rubber preparation methods, that is, mixing, extrusion and vulcanization processes, the finished EPDM sealing rubber ring is obtained, and its performance tests are shown in Table 1.

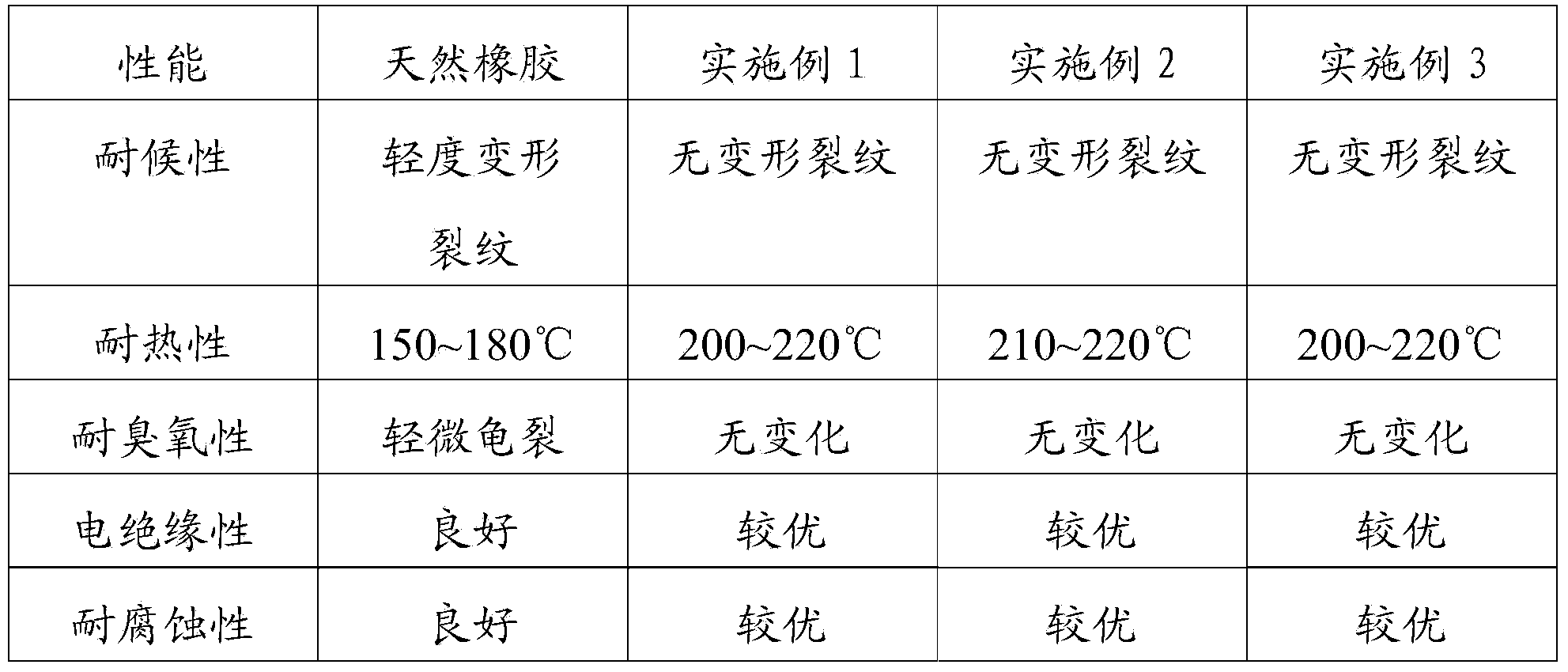

[0022] Table 1 The performance comparison table of each embodiment and natural rubber

[0023]

[0024] As can be seen from Table 1, compared with natural rubber, the weather resistance, ozone resistance and heat resistance of the EPDM rubber obtained by the present invention are significantly enhanced, and also have good electrical insulation and chemical med...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com