Epoxy molding compound filled with high amount of silica powder and preparation method thereof

A technology of epoxy molding compound and silicon micropowder, which is applied in the field of epoxy molding compound and its preparation, can solve problems such as difficulty in adapting to small-profile packaging structures, increased melt viscosity, and affecting processing and molding, and achieves good strength and reduced porosity , Easy to shape and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] First, pulverize the epoxy resin and curing agent to obtain particles with a particle size of less than 3 mm, and then weigh the components according to the proportions in the table below. Heat-melted and mixed uniformly at ~110 ℃, solid flakes are obtained after cooling, pulverized and sieved to obtain particles with a particle size of less than 4 mm, and the pulverized materials are packaged directly or after beating.

[0034]

[0035] The above raw material components are all by weight.

[0036] The epoxy molding compounds obtained from the examples in the table above have been tested and have the technical effects shown in the table below:

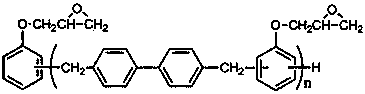

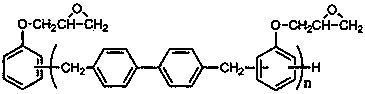

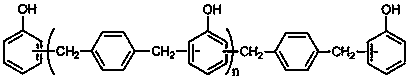

[0037] component specific substance Example 1 Example 2 Example 3 epoxy resin o-Cresol Novolac Epoxy Resin 77 70 70 epoxy resin Epoxy resin containing biphenyl structure 23 28 30 Hardener novolac resin 47.5 49 50 Hardener xylok phenolic resin 2.5 3.5 5 curing acceler...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com