A method of converting cellulose into oil by using green algae

A technology of cellulose and oil, applied in the field of microorganisms, can solve the problem of no cellulose being converted into oil, and achieve the effect of strong degradation of cellulose and short growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

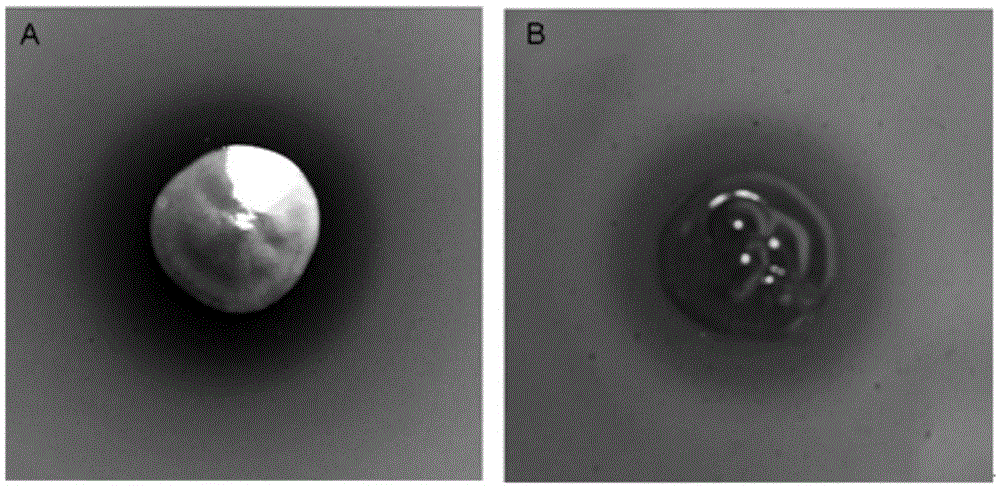

[0014] Example 1. Congo red chromogenic method confirms that A. hainanensis can degrade cellulose under dark conditions

[0015] The medium used is cellulose-MS Congo red medium, and the specific formula is as follows: NH 4 NO 3 1650mgL -l 、KNO 3 1900mgL -l 、KH 2 PO 4 170mgL -l , CaCl 2 2H 2 O440mgL -l , MgSO 4 ·7H 2 O370mgL -l , FeSO 4 ·7H 2 O27.8mgL -l 、Na 2 EDTA37.3gL -l , MnSO 4 4H 2 O22.3mgL -l , ZnSO 4 ·7H 2 O8.6mgL -l 、H 3 BO 3 6.2mgL -l 、KI0.83mgL -l 、Na 2 MoO 4 2H 2 O0.25mgL -l 、CuSO 4 ·5H 2 O0.025mgL -l 、CoCl 2 ·6H 2 O0.0025mgL -l , Inositol 100mgL -l , Glycine 2mgL -l , Thiamine hydrochloride 0.4mgL -l , pyridoxine hydrochloride 0.5mgL -l , Niacin 0.5mgL -l , sucrose 10-30mgL -l , sodium carboxymethyl cellulose 20gL -l , Congo red 200mgL -l , agar powder 9gL -l , pH=6.2.

[0016] The subcultured A. hainanensis was inoculated into the center of the medium plate, and placed in a dark condition for culture at 26°C, and the ...

Embodiment 2

[0017] Embodiment 2. Cultivating Acorns hainanensis in a cellulose-containing liquid medium

[0018] The liquid medium used is MS medium supplemented with shuttlemethyl cellulose, and the specific formula is as follows: NH 4 NO 3 1650mgL -l 、KNO 3 1900mgL -l 、KH 2 PO 4 170mgL -l , CaCl 2 2H 2 O440mgL -l , MgSO 4 ·7H 2 O370mgL -l , FeSO 4 ·7H 2 O27.8mgL -l 、Na 2 EDTA37.3gL -l , MnSO 4 4H 2 O22.3mgL -l , ZnSO 4 ·7H 2 O8.6mgL -l 、H 3 BO 3 6.2mgL -l 、KI0.83mgL -l 、Na 2 MoO 4 2H 2 O0.25mgL -l 、CuSO 4 ·5H 2 O0.025mgL -l 、CoCl 2 ·6H 2 O0.0025mgL -l , Inositol 100mgL -l , Glycine 2mgL -l , Thiamine hydrochloride 0.4mgL -l , pyridoxine hydrochloride 0.5mgL -l , Niacin 0.5mgL -l , glucose or sucrose 30mgL -l Below, sodium carboxymethyl cellulose 20-40gL -l , pH=6.2.

[0019] Inoculate the plate-activated A. hainanensis species in a 500mL Erlenmeyer flask (containing 200mL of the above-mentioned sterilized medium), pre-culture for 10 days at 26...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com