SERS (surface enhanced Raman scattering) device, as well as preparing method and application thereof

A technology of surface-enhanced Raman and scattering devices, applied in Raman scattering, material excitation analysis, etc., can solve the problem of limited SERS effect enhancement, non-adjustable distance between gold nanoparticles in active substrates, and inability to fully utilize gold nanoparticles" "hot spot" effect and other issues, to achieve the effect of wide application prospects and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The concrete steps of preparation are:

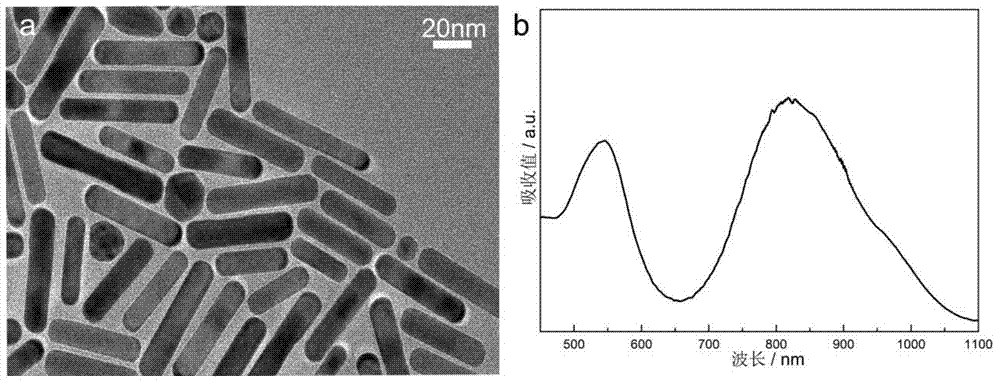

[0044] Step 1: Mix poly(N-isopropylacrylamide), gold nanorods and water in a weight ratio of 1.8:0.003:100 to obtain a mixed colloid.

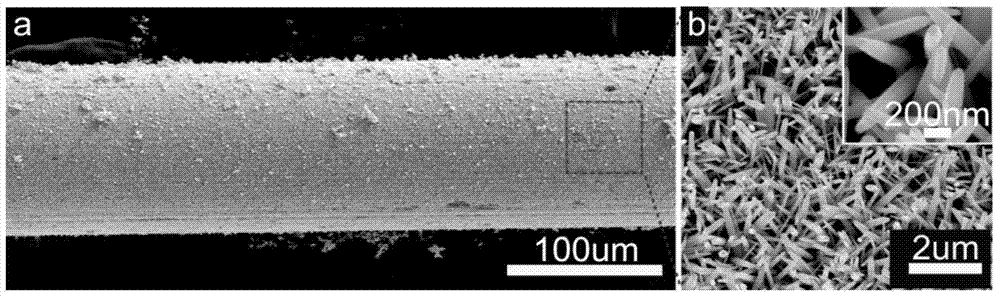

[0045] Step 2, slowly add ammonia water with a concentration of 25wt% to the aqueous solution of zinc nitrate hexahydrate with a concentration of 1.5wt%, until the white precipitate of zinc hydroxide is completely dissolved to obtain an electrodeposition solution. Then, the electric heating wire is used as the cathode, and the graphite is used as the anode, and they are placed in the electrodeposition solution together, and the electrodeposition is carried out at a constant current of 45 μA for 2 hours; among them, the electric heating wire is constantan wire, and the approximate figure 2 a and figure 2 A heating wire with ZnO nanotapered rods standing on its surface shown in b.

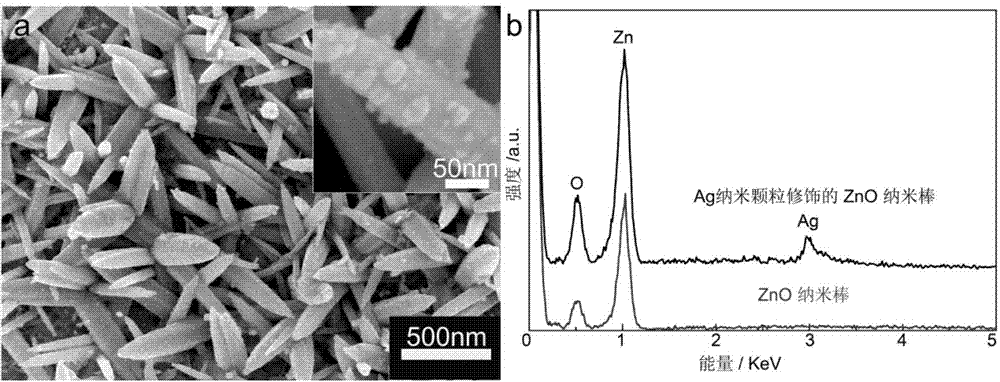

[0046] Step 3, first immerse the heating wire with zinc oxide nano-tapered rods standing on its surface in a silv...

Embodiment 2

[0048] The concrete steps of preparation are:

[0049] Step 1: Mix poly(N-isopropylacrylamide), gold nanorods and water in a weight ratio of 1.9:0.0025:100 to obtain a mixed colloid.

[0050] In step 2, slowly add ammonia water with a concentration of 27 wt% to the zinc nitrate hexahydrate aqueous solution with a concentration of 1.8 wt%, until the white precipitate of zinc hydroxide is completely dissolved to obtain an electrodeposition solution. Then, the heating wire is used as the cathode and the graphite is used as the anode, and they are placed in the electrodeposition solution together, and the electrodeposition is carried out at a constant current of 48μA for 1.8h; among them, the heating wire is constantan wire, and an approximate figure 2 a and figure 2 A heating wire with ZnO nanotapered rods standing on its surface shown in b.

[0051] Step 3, first immerse the heating wire with zinc oxide nano-tapered rods standing on its surface in a silver nitrate solution w...

Embodiment 3

[0053] The concrete steps of preparation are:

[0054] Step 1: Mix poly(N-isopropylacrylamide), gold nanorods and water in a weight ratio of 2.0:0.002:100 to obtain a mixed colloid.

[0055] In step 2, slowly add ammonia water with a concentration of 28 wt% to the zinc nitrate hexahydrate aqueous solution with a concentration of 2.0 wt%, until the white precipitate of zinc hydroxide is completely dissolved to obtain an electrodeposition solution. Then, the heating wire is used as the cathode and the graphite is used as the anode, and they are placed in the electrodeposition solution together, and are electrodeposited at a constant current of 50 μA for 1.5 h; wherein, the heating wire is constantan wire, and the following is obtained: figure 2 a and figure 2 A heating wire with ZnO nanotapered rods standing on its surface shown in b.

[0056] Step 3, first immerse the heating wire with zinc oxide nano-tapered rods standing on its surface in a silver nitrate solution with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Stick length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com