Semiconductor resistance-type gas sensor and preparation method thereof

A gas sensor and semiconductor technology, applied in the direction of material resistance, can solve the problems of high working temperature and low sensitivity, and achieve the effect of low cost, high sensitivity and real-time monitoring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the semiconductor resistive gas sensor of an embodiment of the present invention comprises the following steps:

[0025] (1) Coating the semiconductor colloidal quantum dot solution on the insulating substrate printed with electrodes to form a uniform film. Specifically, the colloidal quantum dots can be coated on the substrate to form a film at room temperature by means of drop coating, spin coating, soaking and pulling, spray coating, printing, and the like.

[0026] (2) Treat the quantum dot film with a short-chain ligand solution to replace the long-chain oleic acid on the surface of the quantum dot, so that gas molecules can easily enter the quantum dot film.

[0027] (3) Removal of residual short-chain ligands and their by-products.

[0028] (4) Steps (1) to (3) are repeatedly performed to obtain a semiconductor colloidal quantum dot film with a desired thickness, and the preparation of the gas sensor is completed.

[0029] The preparat...

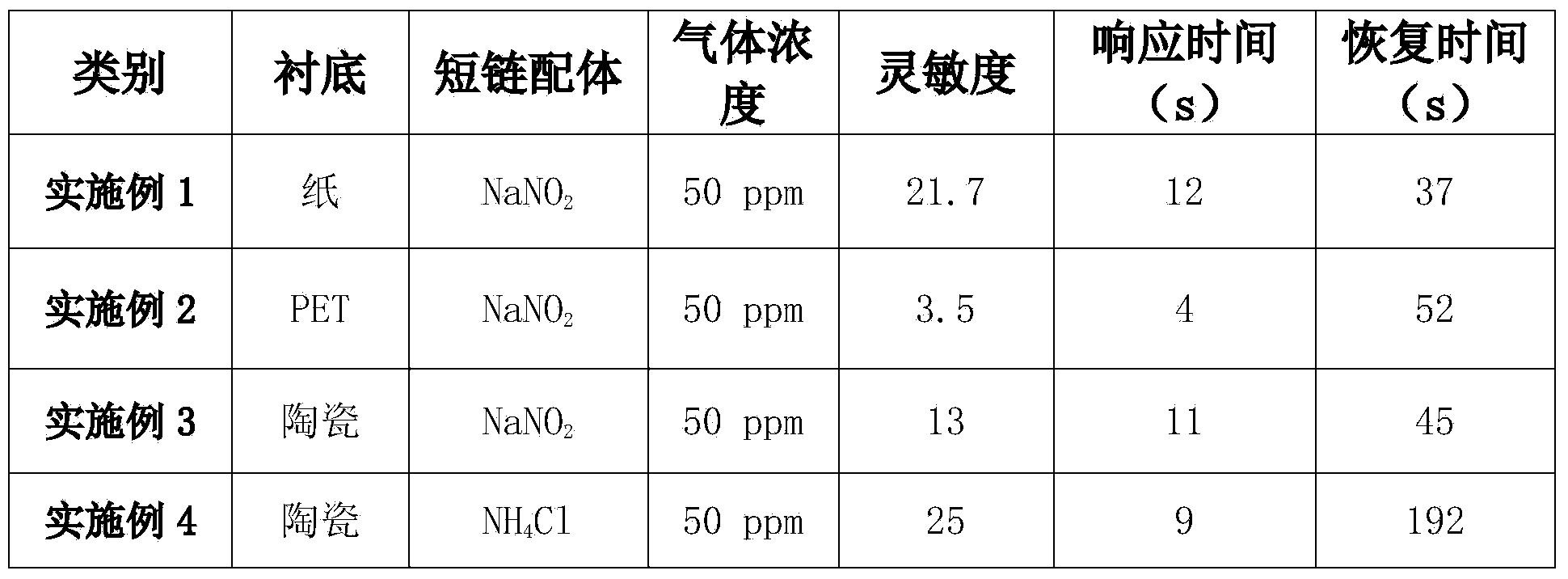

Embodiment 1

[0037] (1) Preparation of PbS colloidal quantum dot solution. PbO is used as the lead source, bistrimethylsilathane (TMS) is used as the sulfur source, and the colloid chemical method is used to generate it.

[0038] Specifically, 0.9 g (4 mmol) PbO was dissolved in 3 ml oleic acid (OA) and 17 ml octadecene (ODE) under nitrogen atmosphere and heated to 90 °C to prepare the precursor of lead oleate as the lead source. After evacuating for 8 hours, the temperature of the precursor was raised to 120°C. Dissolve 180ul (1mmol) TMS into 10ml ODE as sulfur source. Quickly inject the sulfur source into the lead source at 120°C, and after the color of the reaction system turns black (about 15s), put the solution into cold water to quickly drop the temperature to room temperature. Add an appropriate amount of acetone to the cooled solution, centrifuge and stir to remove the supernatant, then disperse with toluene and centrifuge with acetone for multiple cycles until the supernatant is...

Embodiment 2

[0042] The PbS colloidal quantum dot solution prepared in Example 1 is evenly dropped on the PET plastic substrate printed with electrodes, and spin-coated for 15s at a speed of 2500rpm; the sodium nitrite (NaNO 2 ) methanol solution to cover the entire quantum dot film, soak for 45s and dry, repeat twice; wash off residual NaNO with anhydrous methanol 2 Particles and their reaction by-products, soaked for 5s and dried, repeated three times; repeated all the above steps twice to obtain three layers of NaNO 2 The processed lead sulfide quantum dot thin film completed the preparation of the gas sensor.

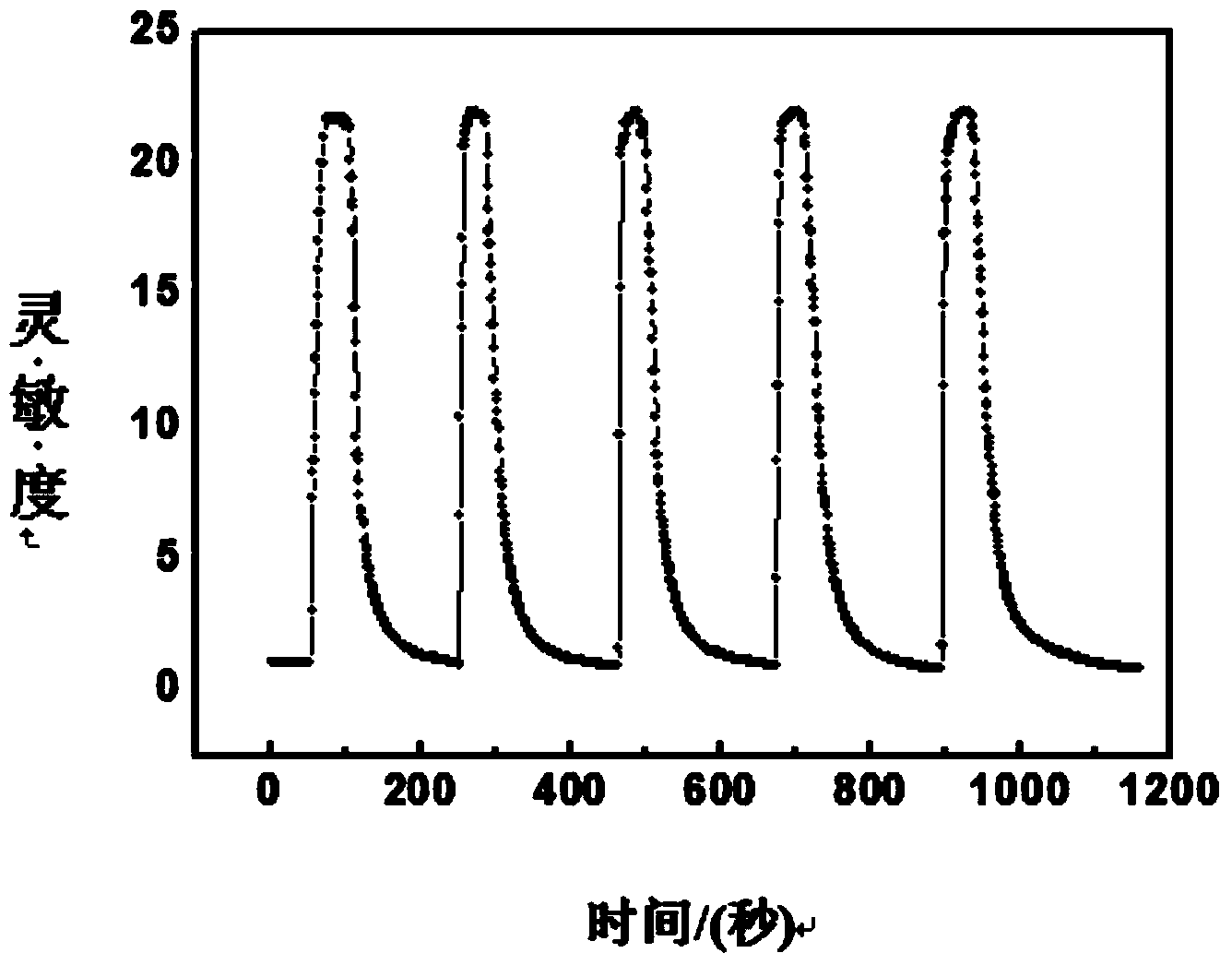

[0043] The response curve of the gas sensor prepared in Example 2 of the present invention to 50 ppm nitrogen dioxide at room temperature was tested.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com