Integration method of high-density thick-film hybrid integrated circuit without lead ball

A thick film hybrid, integrated circuit technology, applied in circuits, electrical components, electrical solid devices, etc., to achieve the effect of reducing volume, improving frequency characteristics and integration, broad market prospects and application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

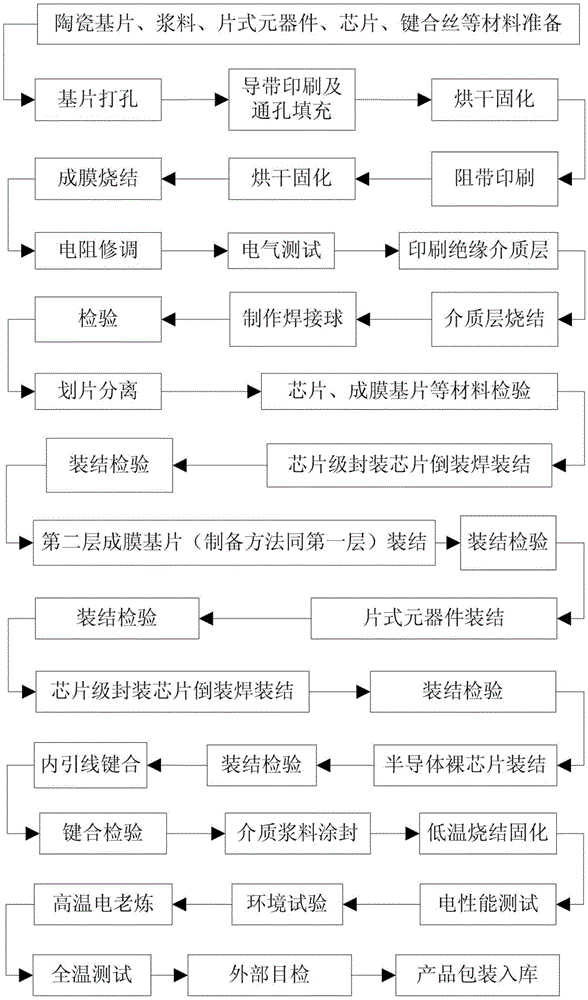

[0022] Example: The technological process of the inventive method is as Figure 11 shown, including the following steps:

[0023] (1) Preparation of ceramic substrate, gold paste, and ruthenium-based resistor paste;

[0024] (2) Cleaning and drying of substrates, cleaning and drying of shells;

[0025] (3) For the printing of thick film conduction tape paste, dry at 150°C for 10 minutes; at the same time, fill with metal paste for through holes;

[0026] (4) Printing of resistance paste, drying at 150°C for 10 minutes;

[0027] (5) Film formation and sintering at 850°C for 10 minutes, and the total film formation time is 35 minutes;

[0028] (6) Laser adjustment resistance;

[0029] (7) Parameter and function test;

[0030] (8) Print aluminum oxide ceramic insulating dielectric paste, sinter at a temperature of 650°C for 60 minutes, and sinter to form a film in a nitrogen-protected environment;

[0031] (9) Gold welding balls are formed by ignition with high-pressure g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com