Polyanion-like lithium ion battery layered positive electrode material and preparation method thereof

A lithium-ion battery and positive electrode material technology, applied in the field of lithium-ion battery materials and electrochemistry, can solve the problems of low conductivity, high conductivity, poor rate performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

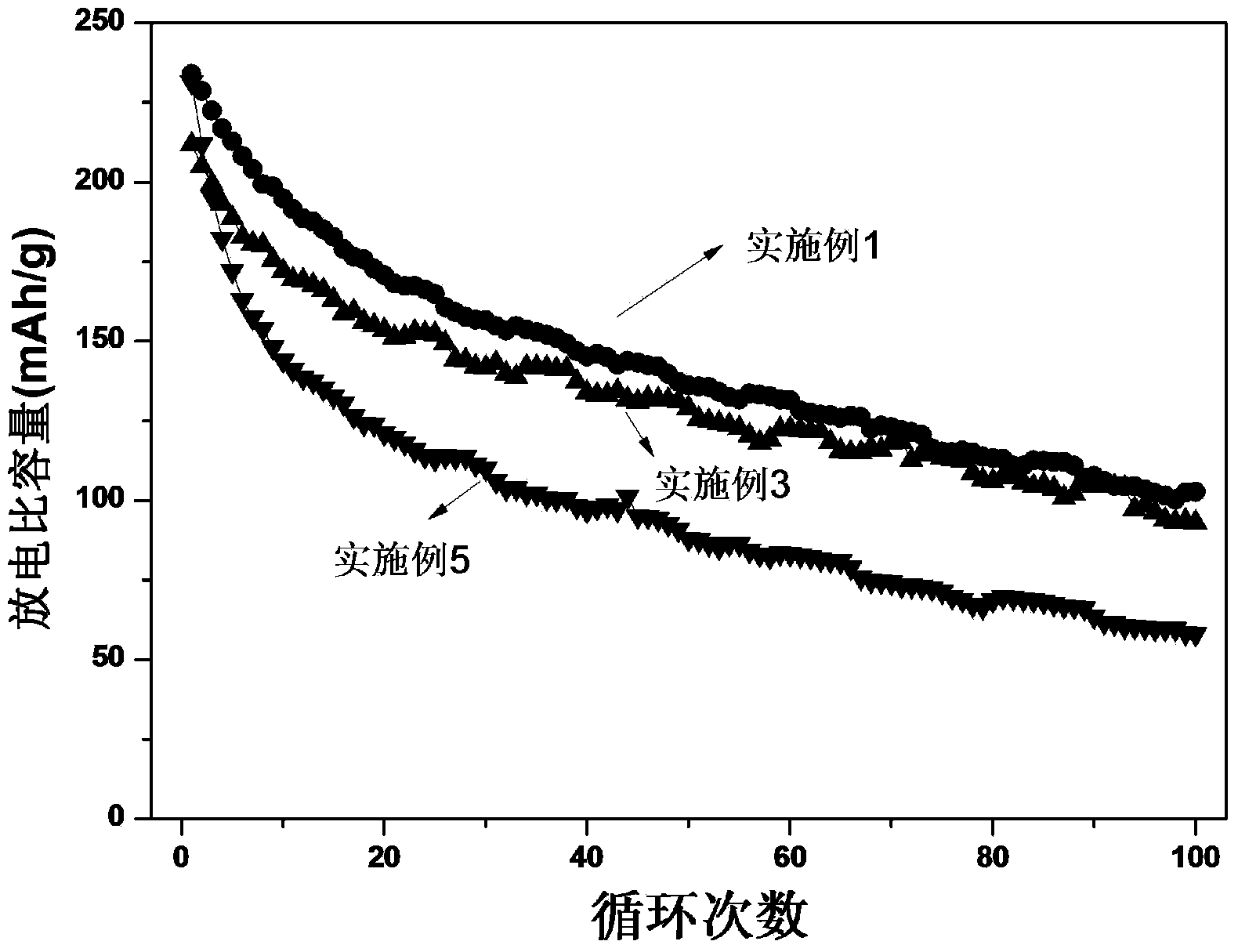

Embodiment 1

[0039] Embodiment 1 solid-phase method synthesizes class polyanion material LiCo(PO 4 ) 0.05 o 1.8

[0040] Take 0.749gLiOH·H 2 O, 1.605gCo 3 o 4 and 0.115gNH 4 h 2 PO 4 Grind after mixing evenly. After grinding evenly, put it in a porcelain boat and place it in a tube furnace for pre-fired at 450°C for 4 hours. Grinding evenly is the target product.

[0041] The target product was mixed with carbon black and PVDF at a mass ratio of 8:1:1, ground evenly with N-methylpyrrolidone as a solvent, then coated on an aluminum foil, and placed in a blast drying oven at 100°C for 1 hour. After taking it out, roll it on a rolling machine several times and cut it into electrode discs. Use this as the positive electrode, use the lithium sheet as the negative electrode, glass microfiber filter paper GF / D produced by whatman company, and the electrolyte is the lithium-ion battery high-voltage electrolyte produced by Beijing Chemical Reagent Research Institute, and pack it into a bu...

Embodiment 2

[0043] Embodiment 2 solid-phase method synthesizes class polyanion material LiCo(PO 4 ) 0.05 o 1.8

[0044] Take 0.749gLiOH·H 2 O, 1.658gCo 2 o 3 and 0.115gNH 4 h 2 PO 4 Grind after mixing evenly. After grinding evenly, put it in a porcelain boat and place it in a tube furnace for pre-fired at 400°C for 5 hours. Grinding evenly is the target product.

[0045] The target product was mixed with carbon black and PVDF at a mass ratio of 8:1:1, ground evenly with N-methylpyrrolidone as a solvent, then coated on an aluminum foil, and placed in a blast drying oven at 100°C for 1 hour. After taking it out, roll it on a rolling machine several times and cut it into electrode discs. Use this as the positive electrode, use the lithium sheet as the negative electrode, glass microfiber filter paper GF / D produced by whatman company, and the electrolyte is the lithium-ion battery high-voltage electrolyte produced by Beijing Chemical Reagent Research Institute, and pack it into a bu...

Embodiment 3

[0047] Embodiment 3 solid-phase method synthesizes class polyanion material LiCo(PO 4 ) 0.1 o 1.6

[0048] Take 0.659gLi 2 CO 3 , 1.605g Co 3 o 4 and 0.196gH 3 PO 4 (Solid) Grind after mixing evenly, put it in a porcelain boat after grinding evenly, place it in a tube furnace and pre-fire it at 500°C for 3 hours, then take it out and grind it again, mix it evenly, and finally put it in a tube furnace again and calcinate at 900°C for 10h , take it out and grind it evenly, which is the target product.

[0049] The target product was mixed with carbon black and PVDF at a mass ratio of 8:1:1, ground evenly with N-methylpyrrolidone as a solvent, then coated on an aluminum foil, and placed in a blast drying oven at 100°C for 1 hour. After taking it out, roll it on a rolling machine several times and cut it into electrode discs. Use this as the positive electrode, use the lithium sheet as the negative electrode, glass microfiber filter paper GF / D produced by whatman company...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reversible discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com