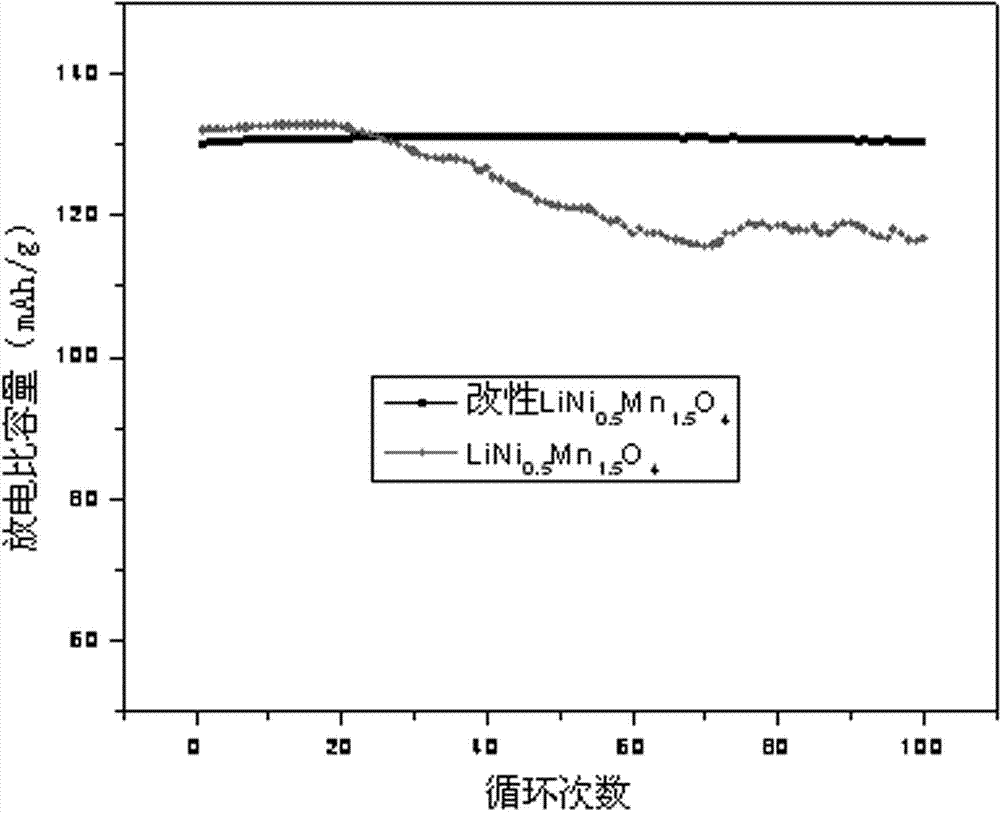

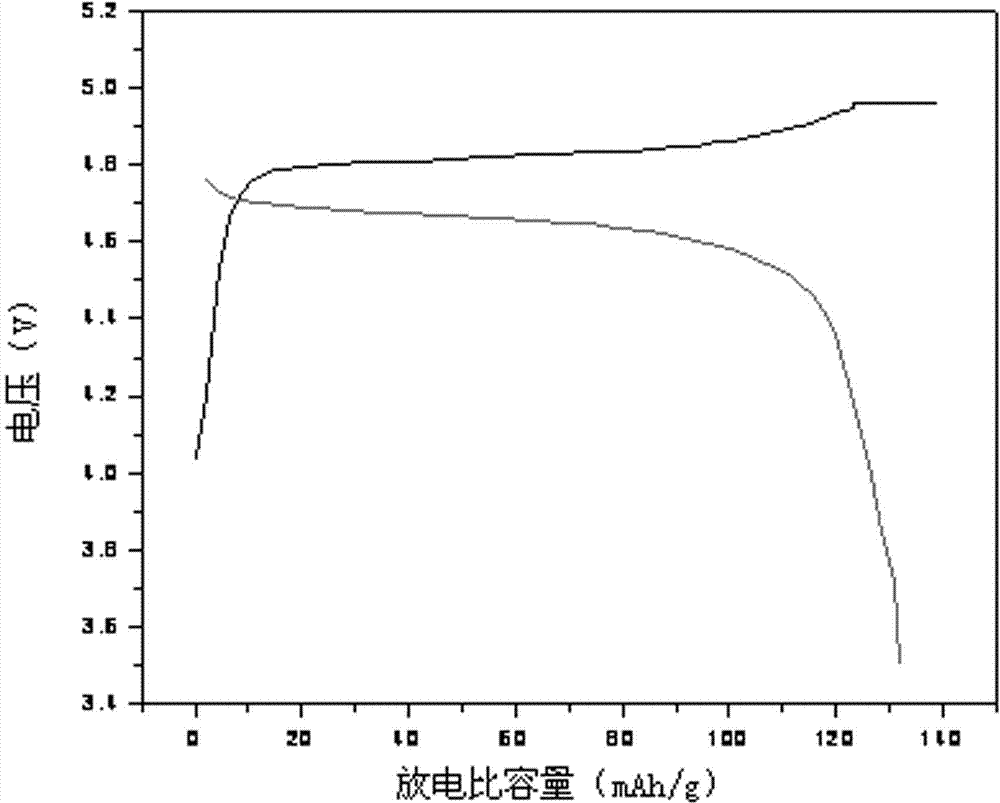

Preparation method for composite modified LiNi0.5Mn1.5O4 cathode material with improved cycle performance

A cathode material, composite modification technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of difficulty in eliminating cathode materials, electrolyte erosion and dissolution, shortening cycle life, etc., and achieve excellent cycle performance. , Strong electron-absorbing ability, reducing the effect of erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weigh 4.31g of nickel sulfate hexahydrate and 8.33g of manganese sulfate monohydrate and dissolve them in 35ml of distilled water, transfer them to a four-necked flask under nitrogen protection, add 15ml of 25% ammonia water dropwise therein, and carry out complexation reaction after the addition is completed 30min, then dropwise add 4mol / L sodium hydroxide 46ml, after the dropwise addition is completed, aging for 5h, after filtering, washing and drying, Ni 0.5 mn 1.5 (OH) 4 Precursor, weighing 5.7g precursor, 1.23g lithium carbonate and 0.06g NH 4F, after mixing, put it in the muffle furnace for sintering at 800°C for 10h in the front section, and sinter at 580°C for 12h in the back section, and then get LiNi after cooling 0.5 mn 1.5 o 3.95 f 0.05 Cathode material, ready for use.

[0024] Weigh 6g LiNi 0.5 mn 1.5 o 3.95 f 0.05 The cathode material is added with dissolved NH 4 In the aqueous solution of F, add a solution containing 0.3g of aluminum nitrate no...

Embodiment 2

[0027] Weigh 3.90g of nickel chloride hexahydrate and 9.75g of manganese sulfate tetrahydrate and dissolve them in 35ml of distilled water, transfer them to a four-neck flask under nitrogen protection, add 23ml of 18% ammonia water dropwise therein, and perform complexation after the addition is completed React for 1h, then dropwise add 4mol / L sodium hydroxide 46ml, after the dropwise addition, age for 6h, filter, wash and dry to obtain Ni 0.5 mn 1.5 (OH) 4 Precursor, weighing 5.7g precursor, 1.23g lithium carbonate and 0.06g NH 4 F, after mixing, put it in the muffle furnace for sintering at 800°C for 10h in the front section, and sinter at 600°C for 10h in the back section, and then get LiNi after cooling 0.5 mn 1.5 o 3.95 f 0.05 Cathode material, ready for use.

[0028] Weigh 6g LiNi 0.5 mn 1.5 o 3.95 f 0.05 The cathode material is added with dissolved NH 4 In the aqueous solution of F, add a solution containing 0.3g of aluminum nitrate nonahydrate, stir for 1 ho...

Embodiment 3

[0031] Weigh 3.90g of nickel chloride hexahydrate and 8.33g of manganese sulfate monohydrate and dissolve them in 35ml of distilled water, transfer them to a four-neck flask under nitrogen protection, add 23ml of 18% ammonia water dropwise therein, and perform complexation after the addition is completed React for 1h, then dropwise add 36ml of 5mol / L sodium hydroxide, after the dropwise addition, age for 6h, filter, wash and dry to obtain Ni 0.5 mn 1.5 (OH) 4 Precursor, weighing 5.7g precursor, 0.75g lithium carbonate and 0.06g NH 4 F, after mixing, put it in the muffle furnace for sintering at 700°C for 15h in the front section, and sinter at 550°C for 10h in the back section, and then get LiNi after cooling 0.5 mn 1.5 o 3.95 f 0.05 Cathode material, ready for use.

[0032] Weigh 6g LiNi 0.5 mn 1.5 o 3.95 f 0.05 The cathode material is added with dissolved NH 4 In the aqueous solution of F, add a solution containing 0.2 g of aluminum nitrate hexahydrate, stir for 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com