Method for resource comprehensive utilization of PTA refining waste water

A technology for refining waste water and recycling, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve problems such as difficult high-value utilization, comprehensive utilization of unrefined waste water, limited water quality, etc., to achieve The effect of reducing consumption, reducing COD discharge, and reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

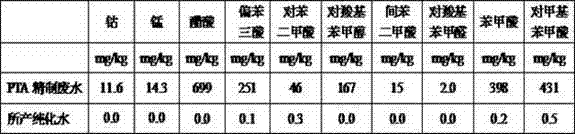

Image

Examples

Embodiment 1

[0024] This example is carried out on a specially constructed pilot plant for comprehensive utilization of PTA refined wastewater.

[0025] This implementation example includes the following 5 steps:

[0026] Step 1, filter the PTA refined wastewater with a filter to remove suspended solids in the water, the filter medium is a filter cloth, and the filter cloth has a pore size of 10 μm;

[0027] In the second step, the filtered water is sequentially passed through the cation exchanger, the first-stage selective adsorber, the second-stage selective adsorber, and the third-stage selective adsorber to obtain purified water;

[0028] In the third step, after the cation exchanger is saturated, it is analyzed with hydrochloric acid, after the first to third-stage selective adsorbers are saturated, it is analyzed with strong alkali, and the analytical solution of the second and third-stage selective adsorbers is removed to waste water;

[0029]In the 4th step, the hydrochloric acid ...

Embodiment 2

[0038] With the same raw material in Example 1, experiment in a similar manner in Example 1, just extract the slurry that crystallizes out in the 4th step with p-xylene, then filter and fully wash the filter cake with PTA refining waste water, the resulting filter cake It is a terephthalic acid product, the filtrate goes to the decanter to separate into oil and water two phases, the water phase goes to waste water, the oil phase is rich in p-toluic acid, and the mass ratio of p-xylene to slurry is 1:5. In this example, the recovery rate of p-toluic acid in the wastewater is 89%, the recovery rate of terephthalic acid is 92%, and the yield of benzoic acid is 73%. The COD flow rate of all discharged wastewater is reduced by 68% compared with the raw material PTA refined wastewater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com