Glass fiber reinforced halogen-free flame-retardant PA6 (Poly Amide 6)/PS (Poly Styrene) alloy material and preparation method thereof

An alloy material and glass fiber technology is applied in the field of glass fiber reinforced halogen-free flame retardant PA6/PS alloy material and its preparation, and achieves the effects of smooth surface, good alloy compatibility and good surface finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

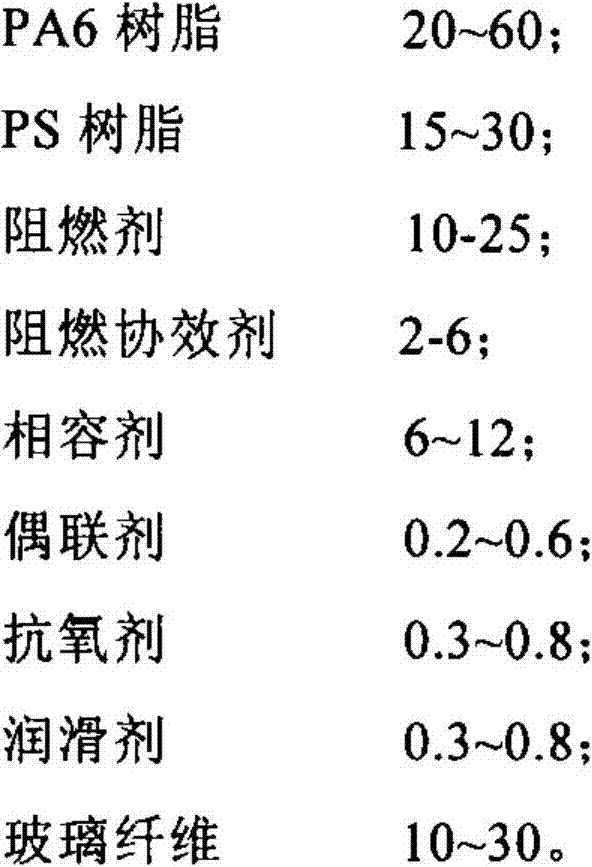

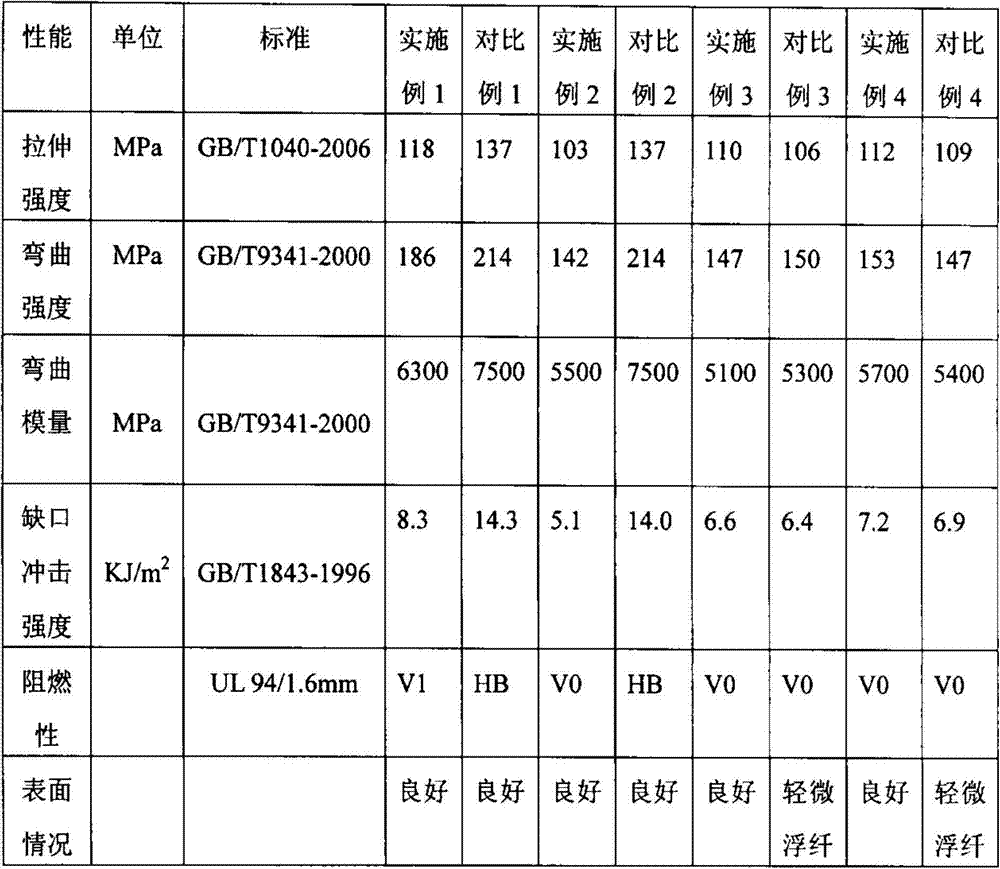

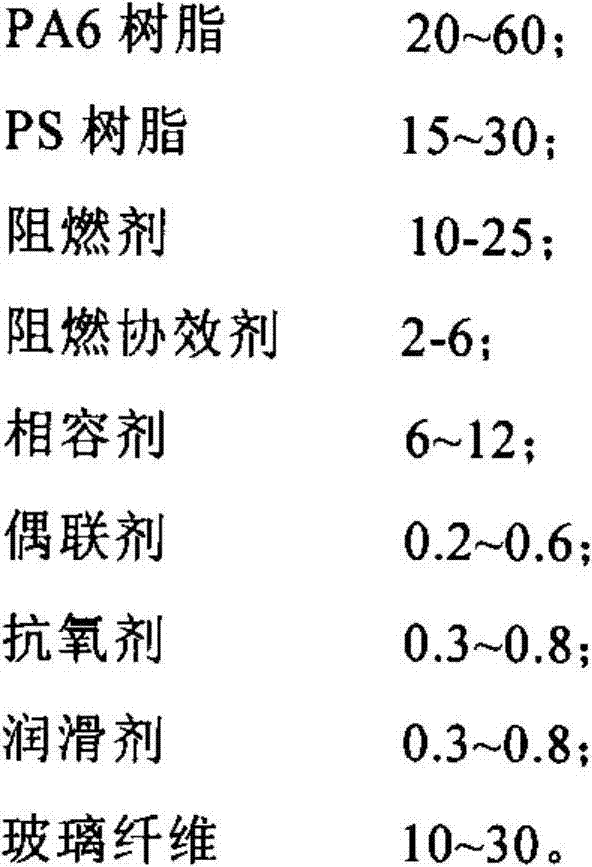

[0034] Embodiment 1 and comparative example 1

[0035] The flame retardant is a halogen-free flame retardant with a molar mass ratio of 4:1, the flame retardant synergist is pentaerythritol, the compatibilizer is acrylonitrile-butadiene-styrene grafted maleic anhydride copolymer, and the coupling agent It is 3-triethoxysilyl-1-propylamine, the antioxidant is a compound of antioxidant 1098 and antioxidant 168 with a weight ratio of 1:1, the lubricant is zinc stearate, glass fiber It is alkali-free glass fiber. Weigh each raw material according to the following parts by weight, and bake PA6 at 100°C for 3 hours:

[0036] Example 1: 30 parts of PA6, 13 parts of PS, 13 parts of flame retardant, 3 parts of flame retardant synergist, 8 parts of compatibilizer, 0.3 part of coupling agent, 0.3 part of antioxidant, 0.3 part of lubricant, 30 parts of glass fiber share.

Embodiment 2 and comparative example 2

[0040] The flame retardant is a halogen-free flame retardant with a molar mass ratio of 4:1, the flame retardant synergist is pentaerythritol, the compatibilizer is acrylonitrile-butadiene-styrene grafted maleic anhydride copolymer, and the coupling agent It is 3-triethoxysilyl-1-propylamine, the antioxidant is a compound of antioxidant 1098 and antioxidant 168 with a weight ratio of 1:1, the lubricant is zinc stearate, glass fiber It is alkali-free glass fiber. Weigh each raw material according to the following parts by weight, and bake PA6 at 100°C for 3 hours:

Embodiment 2

[0041] Example 2: 20 parts of PA6, 15 parts of PS, 20 parts of flame retardant, 4 parts of flame retardant synergist, 8 parts of compatibilizer, 0.3 part of coupling agent, 0.3 part of antioxidant, 0.3 part of lubricant, 30 parts of glass fiber share.

[0042] Comparative example 2: 44 parts of PA6, 15 parts of PS, 8 parts of compatibilizer, 0.3 part of coupling agent, 0.3 part of antioxidant, 0.3 part of lubricant, and 30 parts of glass fiber.

[0043]The specific preparation method is: put other raw materials except glass fiber into a high-efficiency mixer and mix for 10 minutes, and then discharge; put the obtained premix and glass fiber into a twin-screw machine for extrusion and water-cooled granulation, twin-screw The rotating speed of the machine is 200 rpm, and the temperature is 235-255°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com