Low heat loss thermal field system of kyo raw furnace

A kyotoba kiln and heat technology, which is applied in the field of thermal field insulation cover system, can solve the problems of large power consumption and large heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

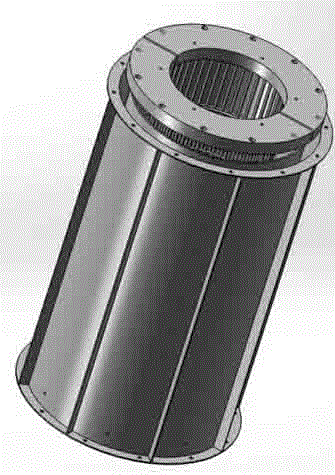

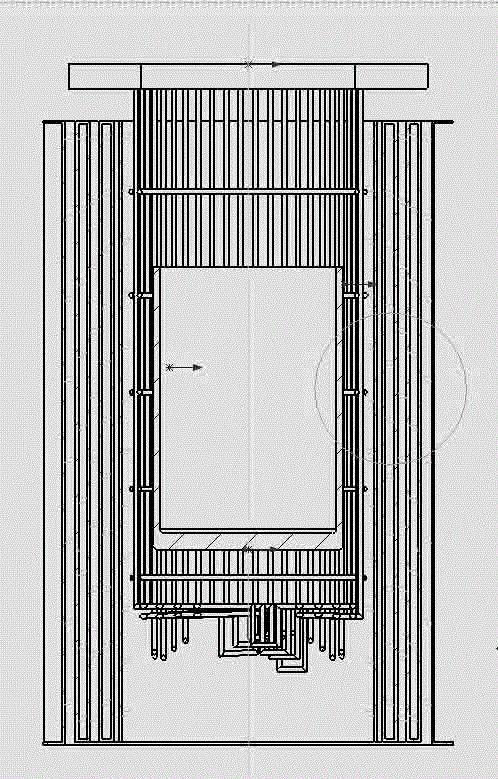

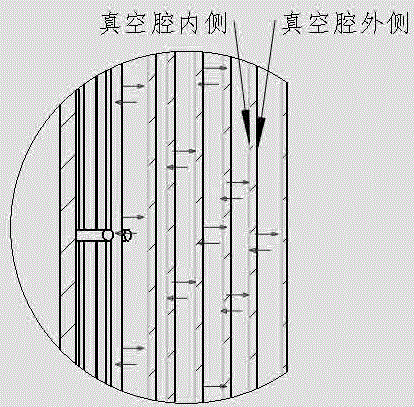

[0011] figure 2 Among them, the outermost layer and the innermost layer of the insulation cylinder are both molybdenum cylinders, and two molybdenum vacuum chambers are nested between them. Because high-temperature volatiles are easily produced in the Kyo Raw Furnace, the molybdenum insulation layer is easily polluted by volatiles. Using a molybdenum vacuum insulation cylinder can not only reduce the number of contaminated molybdenum layers, but also play a role in heat insulation. The inside of each layer of molybdenum is highly polished so that most of the radiant heat is reflected back. During the whole growth process of the crystal in a vacuum environment, the heat is transferred to the molybdenum cylinder through thermal radiation. Under the heat insulation effect of the highly polished molybdenum surface and the vacuum cylinder, the heat is reflected to the greatest extent, reducing the heat exchange of cooling water cool down.

[0012] The thermal field system of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com