Method for quickly detecting starch coated amount in modified calcium carbonate filler through headspace gas chromatography

A technology of headspace gas chromatography and calcium carbonate filler, applied in the field of papermaking, can solve the problems of low accuracy, large sample volume, cumbersome operation, etc., and achieve the effect of high accuracy, simple operation, and improved normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Weigh about 5 grams of modified calcium carbonate filler sample (taken from Fujian Jinjiang Youlanfa Paper Co., Ltd.) and grind it in a mortar for 5 minutes.

[0038] 2) Weigh 0.6769 g (by dry weight) of the ground modified calcium carbonate filler sample and place it in a 20 mL headspace bottle, then rinse the modified calcium carbonate adhered to the wall of the headspace bottle with 4 mL of distilled water Fill and seal the headspace vial with a Teflon / butyl rubber gasket and an aluminum cap. Then add 10 mL of sulfuric acid solution with a concentration of 2 mol / L using a syringe. Finally, the headspace vial loaded with the modified calcium carbonate filler was sonicated for more than 5 minutes.

[0039] 3) After ultrasonic treatment, put the headspace bottle containing the modified calcium carbonate filler sample obtained in step 2) into the headspace autosampler, and keep the temperature at 70°C for 10 minutes, and the gas chromatograph (thermal conductiv...

Embodiment 2

[0048] 1) Weigh about 8 grams of the modified calcium carbonate filler sample (taken from the sample prepared in the laboratory) and grind it in a mortar for 10 minutes.

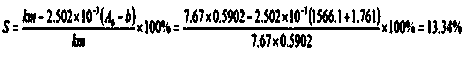

[0049] 2) Weigh 0.5902 g (by dry weight) of the ground modified calcium carbonate filler sample and place it in a 20mL headspace bottle, then rinse the modified calcium carbonate adhered to the wall of the headspace bottle with 4mL distilled water Fill and seal the headspace vial with a Teflon / butyl rubber gasket and an aluminum cap. Then add 10 mL of sulfuric acid solution with a concentration of 2 mol / L using a syringe. Finally, the headspace vial loaded with the modified calcium carbonate filler was sonicated for more than 5 minutes.

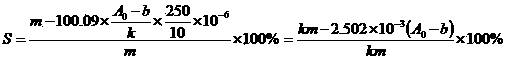

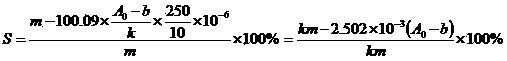

[0050] 3) After ultrasonic treatment, put the headspace bottle containing the modified calcium carbonate filler sample obtained in step 2) into the headspace autosampler, and keep the temperature at 70°C for 10 minutes, and the gas chromatograph (thermal conductivity...

Embodiment 3

[0059] 1) Weigh about 5 grams of modified calcium carbonate filler sample (taken from Fujian Xiyuan Paper Co., Ltd.) and grind it in a mortar for 6 minutes.

[0060] 2) Weigh 0.6201g (by absolute mass) of the ground modified calcium carbonate filler sample and place it in a 20mL headspace bottle, then rinse the modified calcium carbonate adhered to the wall of the headspace bottle with 4mL distilled water Fill and seal the headspace vial with a Teflon / butyl rubber gasket and an aluminum cap. Then add 10 mL of sulfuric acid solution with a concentration of 2 mol / L using a syringe. Finally, the headspace vial loaded with the modified calcium carbonate filler was sonicated for more than 5 minutes.

[0061] 3) After ultrasonic treatment, put the headspace bottle containing the modified calcium carbonate filler sample obtained in step 2) into the headspace autosampler, and keep the temperature at 70°C for 10 minutes, and the gas chromatograph (thermal conductivity detector)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com