Method for preparing one-dimensional silicon nanostructure array on surface of optical fiber

A silicon nano-fiber technology, applied in the field of nanomaterial preparation and application, can solve the problems of difficult long-distance optical fibers, difficult to prepare high aspect ratio nanowires, and preparation of nanostructures, etc., and achieves low cost, uniform and controllable length, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

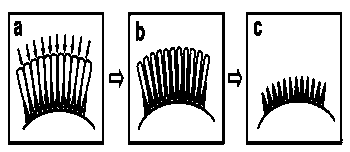

[0019] Refer to the attached figure 1 Describe in detail the concrete steps of the method of the present invention:

[0020] (1) Soak the silica fiber in acetone to remove the polymer cladding. Further, ethanol and deionized water are used to clean the optical fiber.

[0021] (2) Place the cleaned and dried optical fiber in the cavity of the plasma chemical vapor deposition system, and hang it in parallel near the substrate tray. A layer of amorphous silicon with a thickness of several microns is deposited on the optical fiber. The power supply adopts radio frequency or very high frequency, and the power density is 50-100 mW / cm 2 . The substrate tray is not heated. The reaction gas is silane (or diluted by adding an appropriate amount of hydrogen), and an appropriate amount of doping gas, such as phosphine or diborane, can also be added.

[0022] (3) Perform high-temperature annealing on the amorphous silicon deposited on the optical fiber to obtain polysilicon. The anne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com